5 Unique Insights into the Best Metal Shear Machine for Global Buyers

The demand for efficient and precision-driven metal shear machines is at an all-time high as industries continue to seek advanced solutions for metal fabrication. According to a recent market research report, the global metal fabrication market is projected to reach approximately $23 billion by 2026, driven by the rising demand from sectors such as automotive, aerospace, and manufacturing. As businesses strive for enhanced productivity and reduced operational costs, understanding the nuances of various metal shear machine alternatives becomes crucial for global buyers. This blog delves into five unique insights that highlight the best options available, equipping decision-makers with essential knowledge to navigate the complexities of metal cutting technology in an ever-evolving marketplace.

Key Features to Consider in a Metal Shear Machine for Modern Manufacturing Needs

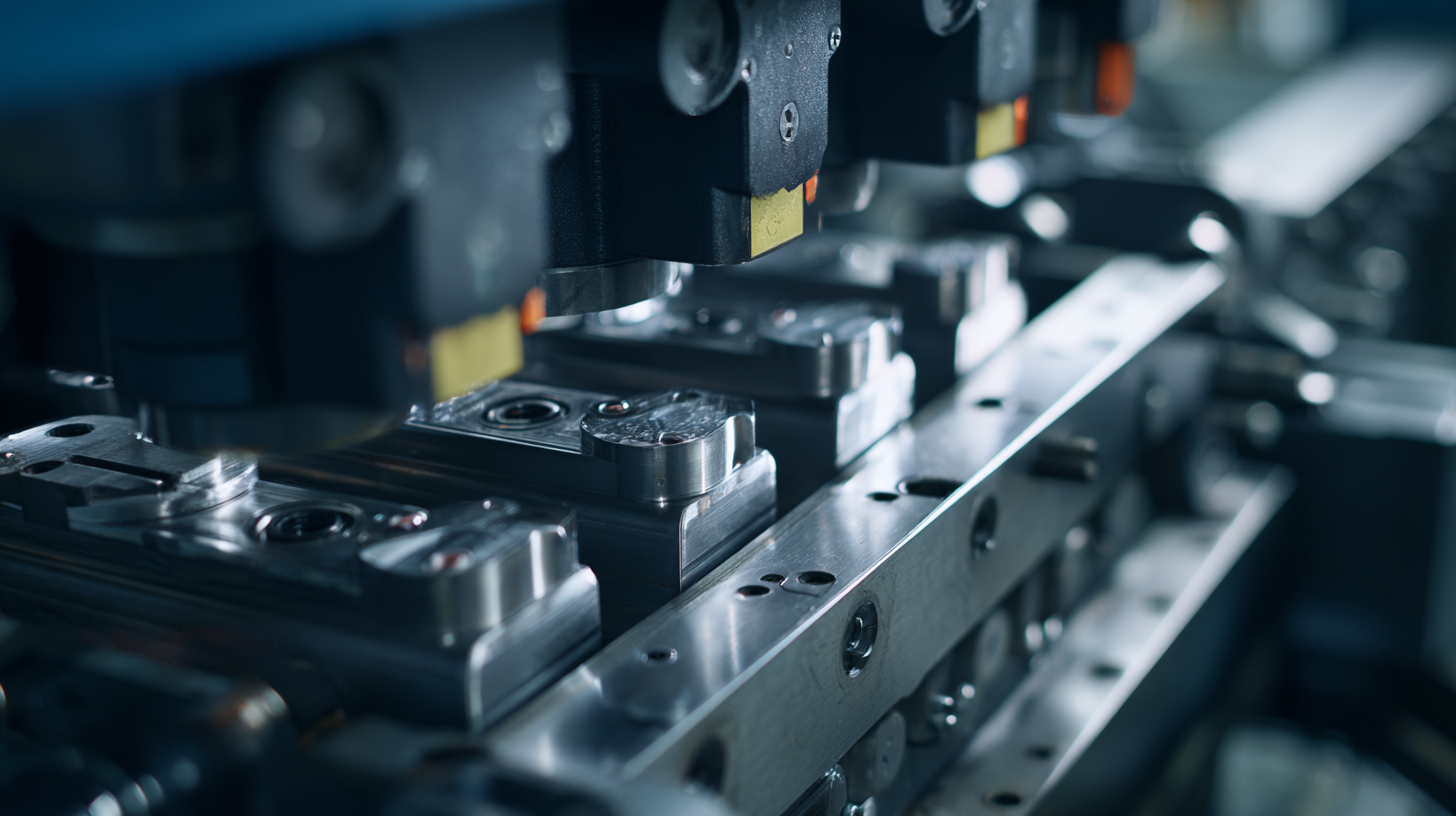

When considering a metal shear machine for modern manufacturing needs, several key features stand out that can significantly impact operational efficiency and productivity. First and foremost, buyers need to examine the type of cutting mechanism employed. Different machines utilize hydraulic, mechanical, or servo-driven systems, each offering distinct advantages depending on the specific materials and thicknesses being processed. According to the latest industry analysis, hydraulic presses dominate the market due to their powerful performance and versatility, representing a substantial portion of the metal forming tools market, projected to reach USD 50 billion by 2030.

Another crucial aspect is the control technology integrated into these machines. Advances in in-process monitoring strategies have revolutionized metal forming, allowing for real-time adjustments based on force, geometry, and temperature measurements. Such capabilities not only enhance precision but also minimize waste—a growing concern in today's sustainability-focused manufacturing landscape. Additionally, as businesses increasingly lean towards automation, the ability of these machines to integrate with modern data systems becomes vital, ensuring seamless operation and efficiency in large-scale production environments. In fact, the rise of Industry 4.0 is influencing metal shear machine designs, pushing manufacturers to innovate and incorporate smarter technologies that cater to the evolving market demands.

Innovative Technologies That Enhance Metal Shear Efficiency and Accuracy

In the ever-evolving realm of metal processing, the efficiency and accuracy of shear machines are paramount. Innovative technologies have emerged, enabling manufacturers to push the boundaries of what's possible. One significant advancement is the integration of computerized numerical control (CNC) systems. These systems allow metal shear machines to execute precise cuts consistently, adapting seamlessly to different material types and thicknesses. With enhanced programming capabilities, operators can achieve intricate designs that were once tedious and imprecise, significantly reducing waste and operational time.

Another groundbreaking innovation is the implementation of laser-guided shearing technology. This approach utilizes laser beams to achieve unparalleled accuracy in alignment and cutting. By projecting the cutting path in real-time, operators can ensure flawless execution, minimizing human error. Additionally, features like automatic load detection and material thickness adjustment further optimize the cutting process, making modern shear machines not only faster but also smarter. As global buyers seek the best solutions for their metal processing needs, understanding these technological advancements is essential in making informed decisions that enhance productivity and ultimately, profitability.

5 Unique Insights into the Best Metal Shear Machine for Global Buyers - Innovative Technologies That Enhance Metal Shear Efficiency and Accuracy

| Feature | Description | Benefit | Application |

|---|---|---|---|

| Hydraulic Drive System | Utilizes hydraulic power for cutting | Provides high cutting force with precision | Metal fabrication, automotive parts |

| CNC Integration | Computer Numerical Control for automated cutting | Enhances accuracy and repeatability | Manufacturing, prototyping |

| Tooling Options | Variety of blades for different materials | Customizable for specific cutting needs | Metal sheets, aluminum, plastics |

| Safety Features | Includes emergency stops and protective guards | Reduces risk of operator injury | Workshops, production lines |

| Energy Efficiency | Designed to reduce power consumption | Lower operational costs | Sustainable manufacturing practices |

Cost-Effectiveness: Investing in the Right Metal Shear Machine for Your Business

Investing in the right metal shear machine is a crucial decision for businesses looking to enhance their production efficiency. According to a report by Research and Markets, the global metal fabrication market is projected to reach $19.74 billion by 2027, indicating a growing demand for high-quality metal processing tools.

Choosing the right shear machine can significantly impact operational costs, as a well-selected device reduces material waste and improves cut precision, leading to better product outcomes and higher profit margins.

Cost-effectiveness extends beyond initial purchase prices. Operational efficiency plays a significant role in total cost ownership. The Fabricators and Manufacturers Association (FMA) states that businesses can save up to 30% in operational costs over five years with energy-efficient machines. Additionally, advancements in technology, such as CNC controls and automation features, allow for faster production cycles and reduced downtime. These enhancements not only streamline the manufacturing process but also facilitate a quicker return on investment, making it imperative for global buyers to consider the long-term benefits of their metal shear machine choices.

Global Trends Shaping the Future of Metal Shear Machines in Various Industries

The global trends shaping the future of metal shear machines are significantly influenced by advancements across various industries. Notably, the metal forming tools market is projected to expand from $29.41 billion in 2025 to an impressive $51.67 billion by 2032, with a compound annual growth rate (CAGR) of 8.4%. This growth is driven by the increasing demand for precision tools that enhance production efficiency and the sustainability of manufacturing processes.

Furthermore, as infrastructural development accelerates worldwide, the rebar cutting tools market is expected to reach $8.2 billion by 2032, enjoying a CAGR of 6.1% over the same period. These figures highlight a robust market environment where innovative technologies and machine performance enhancements are essential. Manufacturers are now focusing on integrating smart features and automation into metal shear machines, aligning with industry needs for sustainability and improved operational efficiency.

The continuous evolution of storage solutions, particularly in energy sectors, also plays a crucial role in shaping metal shear machine designs. As clean and sustainable energy solutions gain prominence, the interplay between energy technologies and metal processing machinery cannot be overlooked, indicating a future where adaptability and innovation are paramount in manufacturing equipment.

User Reviews: Real Experiences with Top Metal Shear Machines Worldwide

User reviews play a crucial role in guiding global buyers toward the best metal shear machines. According to a recent industry report by MarketsandMarkets, the metal cutting machine market is projected to reach $8.1 billion by 2025, driven by the increasing demand for precision cutting in various sectors. Many users highlight that quality and reliability are paramount, with a notable preference for machines equipped with advanced features such as automatic feed systems and programmable controls. These features not only enhance efficiency but also reduce the likelihood of material waste, a critical consideration in today’s eco-conscious market.

When selecting a metal shear machine, users should prioritize machines that have received high ratings for durability and service support. A report from Technavio emphasizes that over 60% of buyers consider post-purchase service quality as a decisive factor in their satisfaction. To ensure a wise investment, potential buyers are advised to seek out reviews from verified users and compare them against industry benchmarks. This approach helps in identifying models that consistently perform well in real-world applications.

Tip: Always look for machines that come with comprehensive warranties and robust customer support. This not only safeguards your investment but also provides peace of mind, knowing that assistance is readily available in case of an issue. Furthermore, connecting with other users via forums or social media groups can offer valuable insights into long-term performance and potential pitfalls of specific models.