Exploring the Unique Features and Applications of Various Best Press Machine Types

In recent years, the press machine industry has witnessed significant advancements, driven by the increasing demand for efficiency and precision in manufacturing processes. According to a report by Grand View Research, the global press machine market is expected to reach USD 26.8 billion by 2025, growing at a CAGR of 4.8%. This growth is fueled by the diverse applications of various types of press machines, including metal stamping, plastic molding, and textile pressing. As manufacturers seek to optimize production capabilities, understanding the unique features and applications of different press machine types becomes crucial.

Moreover, the focus on after-sales service advantages and maintenance costs has never been more pertinent. This blog explores the distinct characteristics of various press machine types while addressing the significance of after-sales support and projections for future innovations in the industry.

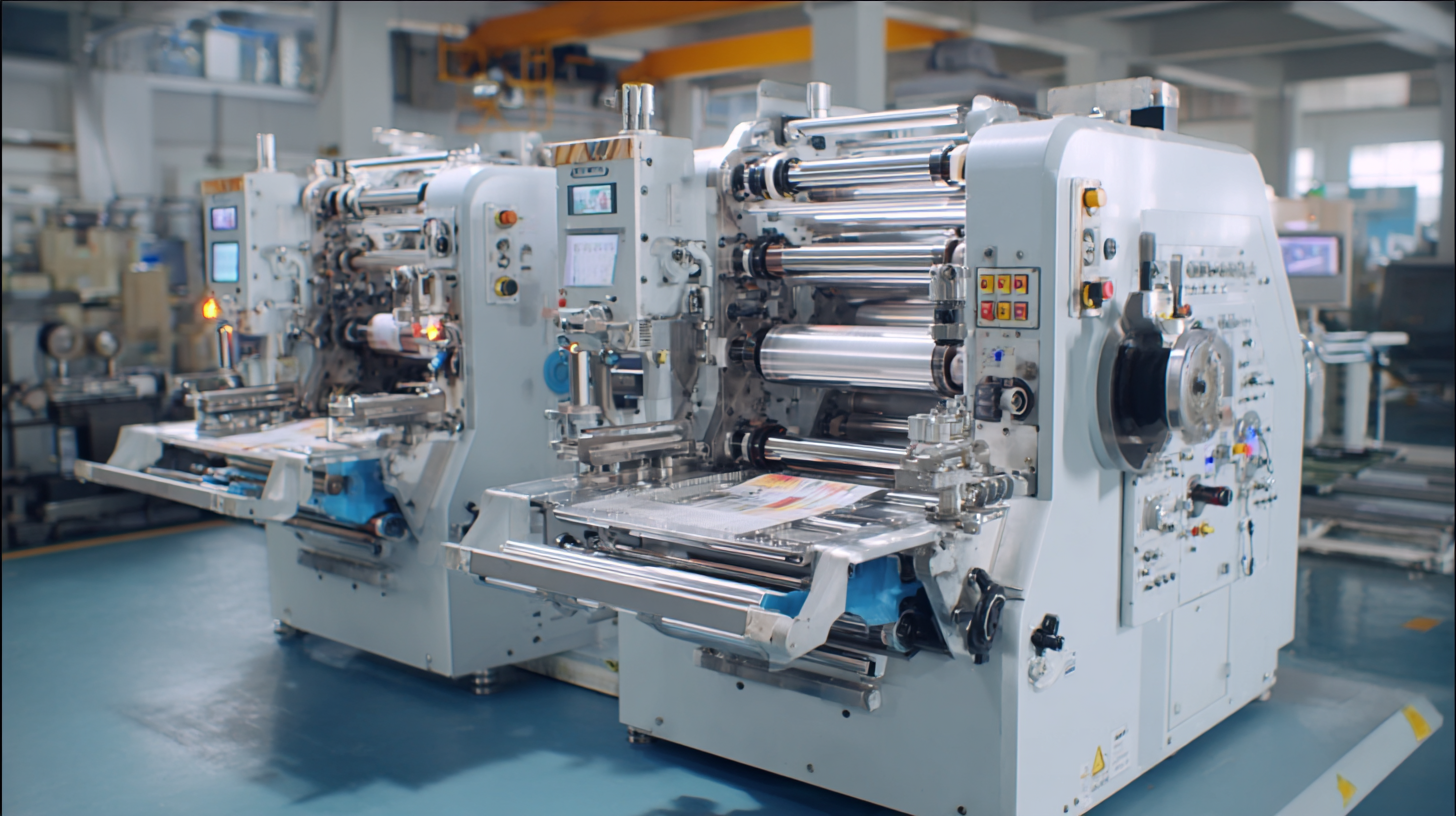

Exploring the Different Types of Best Press Machines and Their Features

When exploring the various types of best press machines, it’s essential to understand their unique features and applications. From heat press machines to heat transfer vinyl (HTV) presses, each type serves distinct purposes in the crafting and garment industry. For instance, according to a report by Allied Market Research, the demand for heat press machines is projected to grow at a CAGR of 4.2% from 2021 to 2028, driven by the increasing popularity of custom apparel and DIY projects. Heat press machines are favored for their ability to transfer designs onto fabrics with precision, making them ideal for small businesses and crafters.

In addition to heat press machines, another notable type is the pneumatic press. This machine harnesses air pressure to ensure a consistent application of force, which significantly improves print quality. Studies indicate that pneumatic presses can reduce production time by up to 30%, a crucial benefit for businesses aiming to enhance efficiency.

**Tip:** When selecting a press machine, consider the scale of your production. For higher volume demands, a pneumatic machine could be a more efficient investment compared to standard heat presses. Always evaluate the technological specifications to ensure compatibility with your materials. This will enhance your production quality and help meet industry standards effectively.

Key Benefits of Using Press Machines for Various Industries

Press machines have become indispensable tools across various industries, offering a range of key benefits that enhance productivity and product quality. According to a report by Grand View Research, the global market for press machines is expected to reach $5.7 billion by 2025, indicating a growing reliance on these machines in sectors such as automotive, aerospace, and manufacturing. Their ability to apply high-force at precise angles allows for efficient metal forming and stamping, which translates into lower operational costs and higher accuracy in production.

In the automotive industry alone, studies show that leveraging advanced press machines can increase production speed by up to 30%. This improvement not only meets the rising consumer demand for vehicles but also contributes to reducing waste material by optimizing the forming process. Additionally, the versatility of press machines, including hydraulic and mechanical types, enables manufacturers to tackle various applications, from delicate components to heavy-duty parts, enhancing their adaptability in the fast-evolving market. As industries strive for sustainability, these machines also offer energy-efficient solutions that align with environmental goals, making them a vital investment for modern production lines.

Comparison of Different Types of Press Machines: Key Benefits

Innovative Applications of Press Machines in Manufacturing Processes

Press machines have revolutionized the manufacturing industry with their innovative applications, significantly enhancing

productivity and efficiency across various sectors. These versatile machines utilize

hydraulic, pneumatic, or mechanical power to shape, mold, and form materials into desired products. One of the most noteworthy applications is in the

automotive industry, where press machines are integral in fabricating body panels, brackets, and other components. The

precision and speed of modern press machines enable manufacturers to produce high-quality parts with minimal waste, ultimately reducing

production costs.

Furthermore, press machines are making strides in the realm of electronics manufacturing. With the

growing demand for compact and lightweight devices, manufacturers are turning to advanced press technologies to create intricate components for

smartphones, tablets, and other gadgets. These machines allow for the precise control of thickness and shape, ensuring that even the most

delicate parts meet stringent specifications. As industries continue to evolve, the adaptability of press machines will play a crucial role in

meeting the ever-changing demands of manufacturing processes, driving innovation and sustainability forward.

Comparative Analysis of Top Press Machine Brands and Models

When it comes to selecting the right press machine, understanding the comparative advantages of top brands and models is crucial. According to a recent industry report by Market Research Future, the global press machine market is projected to reach $8.5 billion by 2025, reflecting a growth rate of 5.2% annually. Key players such as Matsuura Machinery, XLCNC, and Baileigh Industrial dominate the market due to their innovative technologies and robust performance records. Each brand offers distinct features tailored for various applications, making it essential to evaluate specific needs before making a purchase.

For instance, hydraulic press machines are renowned for their high force, making them ideal for metal forming and heavy-duty applications. Conversely, mechanical press machines excel in speed and efficiency, suitable for high-volume production. When choosing a press machine, consider the materials you will be working with and the desired outcome.

**Tip:** Prioritize machines with adjustable stroke lengths for versatility in handling different thicknesses and types of materials.

Additionally, ensure compatibility with automation systems if you plan on integrating new technologies into your workflow. This compatibility can significantly enhance productivity while ensuring seamless operation across multiple processes.

Understanding Quality Standards in Chinese-Made Press Machines

The quality standards of Chinese-made press machines have garnered attention as the global market evolves. According to a recent report by the International Federation of Robotics, the Chinese robotics market is expected to reach $32 billion by 2025, which highlights the increasing importance of manufacturing efficiency and quality in this sector. As China positions itself as a leader in mechanical engineering, ensuring that press machines meet international quality standards becomes crucial for both domestic and export markets.

In 2021, the China Machinery Industry Federation reported that over 70% of Chinese press machine manufacturers are now ISO certified, reinforcing their commitment to quality and reliability. This certification not only aligns with global quality metrics but also enhances the competitive edge of these machines in diverse applications ranging from automotive to electronics manufacturing. With the rise of smart manufacturing practices, Chinese press machines are integrating advanced technologies such as AI and IoT, enabling higher precision and operational efficiency, ultimately contributing to the industry's push towards sustainable practices and lower production costs.