Ultimate Shear Press Guide: Mastering Efficiency and Precision in Your Production Line

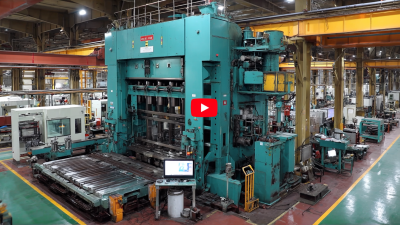

In today's fast-paced manufacturing environment, achieving maximum efficiency and precision is crucial for success, particularly when it comes to operations involving a shear press. This essential tool plays a pivotal role in cutting materials with accuracy, streamlining production lines, and enhancing overall productivity. However, mastering the use of a shear press requires a deep understanding of its mechanics, operational techniques, and best practices.

In this comprehensive guide, we will explore the fundamental concepts and advanced strategies that empower operators and manufacturers to harness the full potential of their shear press systems. From selecting the right equipment to optimizing workflow processes, this "how to" guide aims to equip you with the knowledge and skills necessary to elevate your production capabilities and achieve outstanding results.

Join us as we delve into the intricacies of shear presses and unlock the keys to transformational efficiency in your production line.

Understanding the Basics of Shear Press Operations for Optimal Performance

Understanding the fundamentals of shear press operations is crucial for achieving optimal performance in manufacturing settings. A shear press primarily functions to cut materials with precision and efficiency, and its operational effectiveness significantly impacts production lines. According to a recent industry report by TechSci Research, the global shear press market is projected to grow at a CAGR of 5.2% from 2021 to 2026, underscoring the growing demand for advanced production techniques. This growth emphasizes the need for companies to optimize their shear press operations to stay competitive.

Key aspects of shear press operations include proper machine setup, tooling choice, and regular maintenance. When set up correctly, shear presses can achieve tolerances as tight as ±0.01 mm, which is critical for industries that require high precision, such as aerospace and automotive manufacturing. An analysis by Smithers Pira indicates that inefficient shear press operations can lead to material wastage of up to 20%, directly impacting profit margins. Therefore, understanding and mastering these operational basics not only enhances efficiency but also ensures precision, ultimately driving overall productivity in the manufacturing process.

Key Factors Influencing Efficiency in Shear Press Production Lines

In the rapidly evolving landscape of manufacturing, the efficiency of shear press production lines has become a focal point for industry professionals. Key factors influencing this efficiency include technology advancements, operational precision, and workforce competency. According to recent market analyses, the global metal forming tools market is projected to expand from $29.41 billion in 2025 to $51.67 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 8.4%. This growth is driven largely by increased demand for precision engineering and automation, which enhance the overall throughput of shear press operations.

Moreover, the integration of in-line measurement systems and statistical analyses can significantly influence the efficiency of shear presses. Utilizing high shear wet granulation techniques has shown to improve the flowability of materials, crucial for maintaining production consistency. The emphasis on refining these processes contributes directly to the overall effectiveness of production lines, as faster cycle times and reduced waste lead to cost savings and higher quality outputs. As these innovations continue to evolve, they will likely set new benchmarks for efficiency in the industry, underscoring the importance of staying ahead in technology adoption.

Techniques to Ensure Precision in Shear Press Manufacturing Processes

In the realm of shear press manufacturing, precision is paramount. According to a report by the National Institute of Standards and Technology, manufacturing errors can cost companies up to 10% of their annual revenue. To combat this inefficiency, integrating advanced calibration techniques is essential. Laser alignment systems, for instance, ensure that dies and blades maintain optimal positioning, leading to tighter tolerances and reduced material wastage. By adopting such technology, manufacturers can achieve an impressive reduction in production errors, enhancing overall output quality.

Furthermore, continuous monitoring of shear press operations through data analytics tools helps identify fluctuations in performance and preemptively address potential issues. A 2022 study by the Manufacturing Technology Research Institute found that real-time data analytics could improve production efficiency by up to 25%. Implementing predictive maintenance schedules based on these insights not only minimizes downtime but also extends the lifespan of equipment, making precision and efficiency a sustainable goal in the production line. Therefore, embracing these innovative techniques creates a robust framework for mastery in precision within shear press manufacturing processes.

Common Challenges in Shear Press Operations and How to Overcome Them

In the realm of manufacturing, shear press operations play a pivotal role in achieving high levels of efficiency and precision. However, many companies face common challenges that can hinder productivity. According to a report by the Manufacturing Institute, nearly 60% of manufacturers experience downtime due to maintenance issues. This underlines the importance of regular maintenance schedules and the use of predictive analytics to anticipate equipment failures before they occur.

By integrating IoT technology, companies can monitor shear press performance and reduce unexpected outages.

Another significant hurdle is material wastage, which can account for up to 15% of total production costs, as highlighted by the National Association of Manufacturers. Implementing advanced tooling and optimizing cutting parameters can greatly minimize waste. Studies indicate that companies that invest in high-quality tooling and employ lean manufacturing principles can reduce their material costs by up to 20%.

Enhancing employee training on the operation of shear presses also ensures that workforce skills align with production goals, ultimately leading to improved precision and reduced errors on the production line.

Best Practices for Maintenance and Troubleshooting of Shear Press Equipment

When it comes to maximizing the performance of shear press equipment, maintenance and troubleshooting are essential components that cannot be overlooked. Regular maintenance schedules should be established to ensure that all parts, including blades, hydraulic systems, and controls, are functioning optimally. This includes routine inspections and timely replacement of worn-out components, which can prevent unexpected breakdowns and inefficiencies on the production line. Keeping a detailed maintenance log can also help identify patterns that signal potential issues before they escalate.

In addition to proactive maintenance, effective troubleshooting practices are vital for resolving equipment malfunctions. Operators should be trained to recognize common problems such as misalignment, leakage, or inconsistent cutting quality. Having a structured troubleshooting protocol can significantly reduce downtime. For instance, conducting a thorough analysis of the hydraulic system can reveal pressure issues that may affect cutting precision. Maintaining an organized toolkit with essential spare parts readily available can further enhance repair speed and accuracy, ensuring the production line continues to operate smoothly and efficiently.

Related Posts

-

Unwavering Quality from Trusted Chinese Manufacturers Best Shear Press Solutions

-

What is a Brake Machine? Exploring Its Key Features and Applications

-

The Ultimate Checklist for Sourcing the Best Steel Press Machine for Your Manufacturing Needs

-

Solutions for Optimizing Efficiency with the Best Manual Press Machine

-

Global Reach with China's Top Hydraulic Metal Shear Machines: Precision Engineering Redefined

-

Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs