Solutions for Optimizing Efficiency with the Best Manual Press Machine

In today's manufacturing landscape, the quest for efficiency and productivity is paramount, particularly in industries such as automotive, electronics, and consumer goods. According to a report by Grand View Research, the global manual press machine market was valued at approximately $2.1 billion in 2021 and is projected to grow at a CAGR of 5.6% from 2022 to 2030. This growth underscores the importance of optimizing processes to meet the increasing demand for precision and quality.

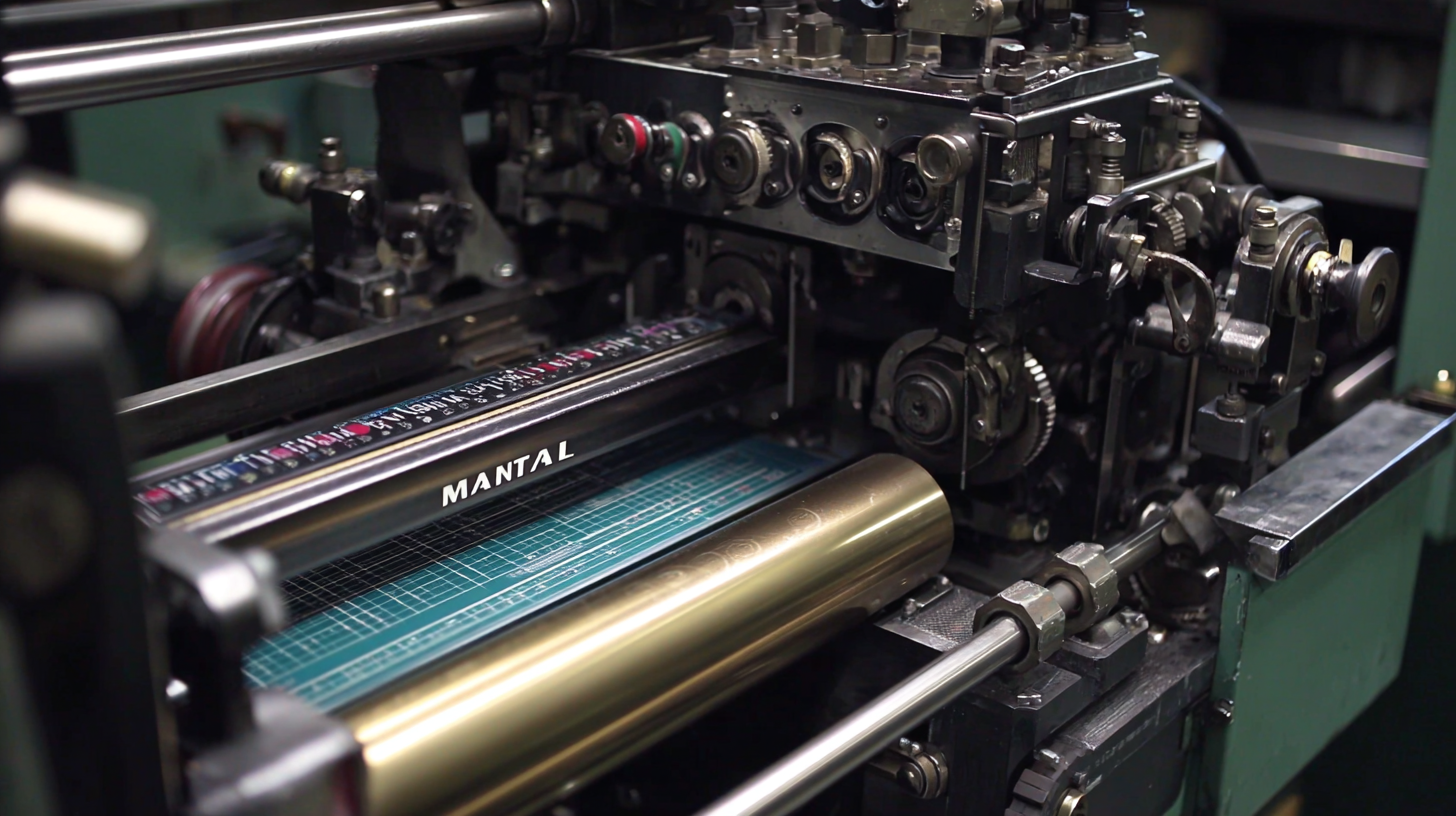

Different types of manual press machines cater to diverse product characteristics and applications, ranging from metal stamping to plastic molding, each offering unique advantages. Understanding these distinctions allows manufacturers to select the most suitable equipment, thereby enhancing operational efficiency and reducing waste. As we explore solutions for optimizing efficiency with the best manual press machines, we will delve into the specific features and suitability of various models to empower businesses in their quest for operational excellence.

Identifying the Key Features of an Efficient Manual Press Machine

When selecting the best manual press machine, identifying key features is crucial for optimizing efficiency. First and foremost, the build quality and material should be considered. A strong, durable frame made from high-quality materials ensures stability during operation and minimizes vibration, leading to more precise and consistent results.

Additionally, the weight of the machine can influence its performance; a well-balanced press allows for better control and maneuverability, enabling users to work more effectively.

Another important aspect to evaluate is the press mechanism itself. Look for machines that offer adjustable pressure settings to accommodate various materials and thicknesses, making them versatile for different projects. Speed and ease of operation are also vital; features like ergonomic handles and simple ratchet mechanisms can significantly reduce user fatigue during repetitive tasks.

Furthermore, accessibility in terms of tool changes and maintenance plays a pivotal role in sustaining productivity. In summary, focusing on these key features can greatly enhance the performance of a manual press machine, ultimately contributing to more efficient workflows.

Essential Maintenance Tips for Longevity and Optimal Performance

To ensure the longevity and optimal performance of manual press machines, proper maintenance is paramount. According to the American Society of Mechanical Engineers, regular maintenance can increase equipment lifespan by up to 30%. Operators should follow a consistent maintenance schedule that includes daily inspections, lubrication, and cleaning to prevent wear and tear. For instance, keeping moving parts free of debris and adequately lubricated can reduce friction, which is crucial considering that friction-related issues account for approximately 40% of machinery failures.

Additionally, utilizing the right tools and techniques during operation can greatly enhance efficiency. A report by the Machinery Maintenance Institute emphasizes that aligning the machine components correctly can further improve operational performance by about 15%. Furthermore, the use of high-quality replacement parts not only ensures safety but also maintains the machine's integrity, which, as industry studies have shown, can lead to a significant reduction in downtime. Investing in training for operators on best practices in machine handling and maintenance can also make a substantial difference in the overall efficiency of the manual press machines.

Techniques for Maximizing Output with Manual Press Operations

Maximizing output in manual press operations hinges on a combination of effective techniques and practical insights drawn from industry best practices. Research indicates that organizations utilizing manual press machines can enhance their productivity by up to 30% through optimized workflow management. This can be achieved by meticulously scheduling machine operation times, minimizing downtime, and ensuring that all necessary tools and materials are accessible before starting production.

Another key technique for increasing efficiency is operator training. A comprehensive training program can lead to a significant decrease in errors and rework, which a report from the Manufacturing Institute highlights can account for as much as 20% of total production costs. By investing in skilled operators who are well-versed in the nuances of their equipment, businesses can not only improve output but also maintain high-quality standards. Implementing lean manufacturing principles can further streamline manual press operations, enabling teams to identify and eliminate waste, ultimately leading to smoother, faster production cycles.

Comparative Analysis: Manual Press vs. Automatic Press Efficiency

When considering efficiency in manufacturing, the choice between a manual press and an automatic press can significantly impact productivity. Manual presses offer flexibility and lower initial costs, making them ideal for small businesses or specialized tasks. However, as production demands increase, the limitations in speed and consistency of manual presses become evident compared to their automatic counterparts, which are designed to handle high-volume tasks with precision and reduced labor input.

To optimize efficiency with a manual press, it's essential to focus on workflow and setup time. One tip is to invest time in perfecting the training of operators to ensure they can work swiftly and accurately. Additionally, organizing tools and materials efficiently within reach can drastically reduce downtime during operation.

Another useful approach is to evaluate the type of work being done. For tasks requiring frequent changes or customization, a manual press allows for quick adjustments, which can be a significant advantage. Balancing these factors against the capabilities of automatic presses is crucial; if consistency and volume are more critical, an automatic solution may ultimately provide better overall efficiency.

Integrating Technology: Enhancing Manual Press Operations with Digital Tools

In today’s manufacturing landscape, integrating technology with traditional manual press operations can lead to significant efficiency gains. A recent industry report from the Automation & Robotics Association highlights that manufacturers leveraging digital tools alongside manual processes can improve productivity by up to 30%. This enhancement is largely due to the seamless flow of information and improved workflow coordination facilitated by digital platforms. By adopting technologies like IoT sensors and real-time data analytics, operators can closely monitor the performance of manual presses, leading to quicker decision-making and increased operational efficiency.

Moreover, the introduction of software solutions designed for manual operations is transforming how workshops manage their processes. According to a study by TechResearch, implementing digital management tools can reduce setup times by as much as 20%. These tools not only allow for better scheduling of jobs but also provide insightful data that can inform maintenance schedules, minimizing downtime. This synergy between manual presses and innovative digital solutions exemplifies how traditional manufacturing practices can be enhanced, making them more competitive in a rapidly evolving market.