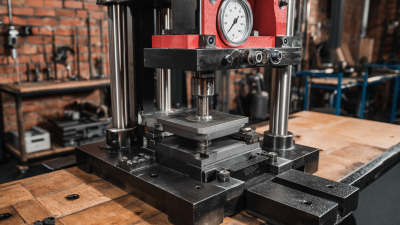

How to Optimize Your Production Process with a Manual Press Machine

In the manufacturing landscape, optimizing production processes is essential for enhancing efficiency and reducing costs. According to a report by the Association of Manufacturing Technology, companies that implement efficient machinery, such as a manual press machine, can see productivity boosts of up to 30%. These machines offer versatility and can be adapted for various applications, making them invaluable in industries ranging from automotive to electronics.

Additionally, a study conducted by the National Institute of Standards and Technology highlights that organizations leveraging manual press machines can significantly minimize material waste, ultimately contributing to more sustainable practices.

As businesses strive to improve their operational workflows, understanding how to effectively utilize a manual press machine can play a crucial role in achieving production goals and maintaining a competitive edge in the marketplace.

Identifying Key Areas for Optimization in Manual Press Operations

Manual press machines play an essential role in various manufacturing processes, and optimizing their operations can significantly enhance productivity. Identifying key areas for optimization involves examining the workflow, material handling, and equipment maintenance practices. According to a review conducted by the University of Texas at Arlington, incorporating industrial engineering tools can streamline processes, reduce waste, and improve overall efficiency. For instance, addressing ergonomic factors and machine setup times directly contributes to shorter cycle times and increased throughput.

Furthermore, leveraging advancements in artificial intelligence (AI) can lead to remarkable improvements in manual press operations. AI-driven solutions can analyze operational data to identify bottlenecks and suggest process adjustments. A recent study highlights how optimizing energy transitions with AI not only enhances overall output but also improves cost management through better resource allocation. By systematically evaluating these areas, manufacturers can create a more sustainable and efficient workflow that drives profitability while maintaining high-quality standards in their production lines.

Choosing the Right Materials for Enhanced Production Efficiency

Choosing the right materials is crucial for optimizing production efficiency when utilizing a manual press machine. According to a report by the Manufacturing Institute, selecting high-quality materials can improve production speed by up to 30%. Materials that are specifically designed for compatibility with manual press machinery can minimize wear and tear, thereby reducing maintenance costs and downtime. For instance, using advanced composites rather than traditional metals can enhance the durability of the products while allowing for more intricate designs.

In addition, the right materials can significantly impact the overall product quality. A study by the Society of Manufacturing Engineers indicated that using materials with superior tensile strength can lead to a reduction in material waste by approximately 15%, emphasizing the importance of not only selecting high-performance materials but also considering their sustainability. When manufacturers invest in the right materials, they are not only optimizing their production processes but also aligning with industry trends toward more sustainable practices, which can enhance their brand reputation and customer loyalty.

Implementing Best Practices for Machine Maintenance and Care

Implementing best practices for machine maintenance and care is crucial for optimizing your production process with a manual press machine. According to a 2022 report by the Manufacturing Institute, 34% of machine downtime is attributed to inadequate maintenance practices. Regular maintenance not only extends the life of your equipment but also enhances operational efficiency, thus decreasing unexpected failures that could disrupt production.

One effective strategy is to establish a routine maintenance schedule. This should include tasks such as lubrificating moving parts, checking for wear and tear, and recalibrating settings. A study by the American Society of Mechanical Engineers reveals that companies adhering to structured maintenance programs experience a 30% increase in productivity.

Tip: Keep a detailed log of all maintenance activities and inspections. This can help identify patterns and predict potential issues before they arise.

Additionally, training operators on proper machine care is vital. According to a report by the National Association of Manufacturers, enhancing operator knowledge regarding maintenance protocols can reduce breakdowns by up to 25%.

Tip: Implement regular training sessions for your staff, focusing on both operational proficiency and maintenance tasks.

Training Workers for Maximum Productivity and Safety

Training workers on the effective use of a manual press machine is crucial to maximizing productivity while ensuring safety in the production environment. It begins with a comprehensive training program that covers the machine's operational principles, proper handling techniques, and the importance of adhering to safety protocols. Workers must be familiar with the machine's components, as well as the adjustments required for different tasks. Understanding the workflow and potential hazards associated with manual press operations enhances their confidence and competence.

Additionally, ongoing training and assessment are essential in maintaining high productivity levels. Regular workshops can keep the workforce updated on best practices, new techniques, and any modifications to safety standards. Implementing a mentorship system, where experienced workers guide newcomers, can significantly enhance skill acquisition and adherence to safety measures. This investment in training not only optimizes the production process but also fosters a culture of safety, reducing the likelihood of accidents and improving overall operational efficiency.

Analyzing Production Data to Drive Continuous Improvement

Optimizing your production process with a manual press machine requires a keen analysis of production data to foster continuous improvement. Integrating real-time data collection allows manufacturers to track efficiency, identify bottlenecks, and refine workflows. According to a report by the American Society for Quality, organizations that implement data-driven decision-making can improve their operational efficiency by up to 15%. This highlights the importance of leveraging production data for informed strategic changes.

One critical element of analyzing production data is to establish key performance indicators (KPIs) that align with your operational goals. These KPIs can include cycle times, defect rates, and overall equipment effectiveness (OEE). Regularly reviewing these metrics provides insights into where processes may fall short and where adjustments can yield the greatest returns.

**Tip:** Implement visual management tools such as dashboards that present real-time KPIs for easy monitoring. This not only keeps your team informed but also fosters a culture of transparency and proactive problem-solving.

Furthermore, don't hesitate to compare your findings against industry benchmarks. For instance, a study by the Manufacturing Institute found that companies employing data analytics had a productivity rate 20% higher than those who did not. Embracing this analytical mindset allows for sustained improvement and helps maintain a competitive edge in the market.

**Tip:** Schedule routine training sessions with your team to discuss data findings and promote collective brainstorming for process improvements. Engaging employees in these discussions encourages ownership and can lead to innovative solutions.

Production Efficiency Analysis Over Six Months

This bar chart illustrates the production output over a six-month period. The increasing trend signifies improvements in the production process, likely driven by effective use of the manual press machine and data analysis for continuous improvement.

Related Posts

-

What is the Importance of Manual Press Machines in Modern Manufacturing

-

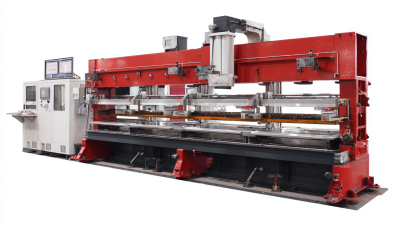

Solutions for Optimizing Efficiency with the Best Manual Press Machine

-

How to Effectively Use a Manual Press Machine for Optimal Results

-

The Definitive Handbook to Sheet Metal Press Machines: Mastering Efficiency and Innovation

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

15 Best Shear Press Machines for Maximum Efficiency in Manufacturing