How to Optimize Efficiency with Hand Press Machines in Your Production Line

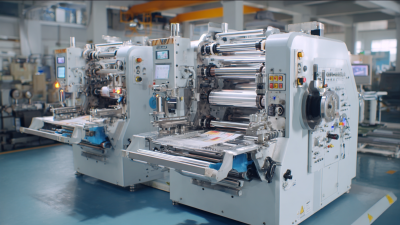

In today's fast-paced manufacturing environment, optimizing efficiency is crucial for staying competitive, and one of the tools that can significantly contribute to this goal is the hand press machine. These versatile machines are designed to provide precise mechanical force, allowing for a range of applications from assembly to material processing. By incorporating hand press machines into your production line, businesses can not only streamline their workflows but also enhance productivity and reduce labor costs. This blog will explore the various types of hand press machines available, their unique features, and the key strategies for effectively integrating them into your operational processes. Understanding how to harness the power of a hand press machine can lead to substantial improvements in efficiency and overall performance on the production floor.

Benefits of Hand Press Machines: Understanding Production Efficiency Gains

Hand press machines are a valuable asset in any production line, particularly due to the increased efficiency they can bring to various manufacturing processes. One of the main benefits of using hand press machines is their ability to ensure precision in production, resulting in a more streamlined workflow. With a well-calibrated hand press machine, operators can achieve consistent results while reducing the risk of errors that can slow down the production process.

To maximize the efficiency of hand press machines, companies should consider investing in regular maintenance to keep the equipment in top shape. Additionally, training operators on the correct handling techniques can minimize downtime and enhance productivity. Implementing a system to monitor usage and performance can also highlight areas where improvements are needed, facilitating further enhancement of production efficiency.

Another important tip for optimizing efficiency is to analyze the layout of the production line. Hand press machines should be positioned to allow for easy access and minimal movement for operators. This setup reduces fatigue and speeds up the overall manufacturing process, ultimately leading to greater productivity and profitability. By leveraging the advantages of hand press machines thoughtfully, production lines can attain significant efficiency gains.

How to Optimize Efficiency with Hand Press Machines in Your Production Line

| Dimension | Metric | Value | Description |

|---|---|---|---|

| Production Time | Hours per Week | 40 | Standard working hours for production |

| Units Produced | Units per Hour | 100 | Total units produced during working hours |

| Overall Equipment Effectiveness (OEE) | Percentage | 85% | Measure of manufacturing efficiency |

| Waste Rate | Percentage | 5% | Proportion of materials wasted during production |

| Labor Efficiency | Units per Employee | 200 | Number of units produced per employee per shift |

Maximizing Output: Key Metrics for Hand Press Machine Utilization

Maximizing the output of hand press machines is essential for enhancing productivity in any production line. One key metric to consider is the Overall Equipment Effectiveness (OEE), which combines machine availability, performance efficiency, and quality rate into a single score.

Maximizing the output of hand press machines is essential for enhancing productivity in any production line. One key metric to consider is the Overall Equipment Effectiveness (OEE), which combines machine availability, performance efficiency, and quality rate into a single score.

According to the Manufacturing Performance Benchmarking report by the Aberdeen Group, organizations with well-monitored OEE metrics can achieve up to a 25% increase in manufacturing output. This highlights the importance of regular maintenance schedules and timely interventions to minimize downtime, ultimately leading to a more efficient production process.

Another critical metric is cycle time, which refers to the total time it takes to complete one cycle of operation. In many cases, optimizing cycle time can lead to significant productivity gains. Research by the Lean Manufacturing Institute shows that reducing cycle time by just 10% can directly translate to a 15% increase in daily output for hand press machines.

By employing techniques such as process mapping and root cause analysis, companies can identify bottlenecks and streamline operations, ensuring that hand press machines are utilized to their fullest potential while maintaining high quality standards.

Common Challenges in Hand Press Operations and Their Solutions

In hand press operations, several common challenges can hinder productivity and efficiency. One significant issue is inconsistency in pressure application, which can lead to variations in product quality. To combat this problem, it's essential to implement standardized training for operators, ensuring they understand the importance of consistent force application. Additionally, regular maintenance checks on the hand press machines can help identify any wear or malfunction, allowing for timely repairs and preventing issues that could arise during production.

Another challenge is the ergonomic strain on operators due to repetitive motions and awkward postures. This can lead to decreased efficiency and increased injury risk over time. Introducing adjustable workstations and promoting the use of ergonomic hand tools can significantly improve comfort for operators. By providing training on proper body mechanics and regular breaks, employers can ensure a healthier, more productive workforce, ultimately leading to better output and reduced absenteeism.

Efficiency Optimization with Hand Press Machines

This chart illustrates various efficiency metrics related to hand press machine operations, including cycle time, downtime, setup time, and quality defects. These metrics provide insight into common challenges in hand press operations and help identify areas for improvement.

Case Studies: Real-World Examples of Hand Press Machines Enhancing Productivity

Hand press machines are transforming production lines across various industries by enhancing productivity and efficiency. A recent report from the Manufacturing Institute reveals that incorporating hand press machines can improve operational efficiency by up to 20%, significantly reducing the time needed for assembly and fabrication tasks. For example, a leading automotive parts manufacturer implemented hand press technology, resulting in a 30% reduction in cycle time, which allowed them to scale their production output without the need for extensive workforce expansion.

In the electronics sector, a case study involving a major consumer electronics firm highlighted how hand press machines streamlined their production process. By switching to these machines, the company not only increased its precision in component assembly but also decreased waste by 15%, leading to both cost savings and improved product quality. With precision and user-friendliness at the forefront, hand press machines have proven to be essential tools that drive efficiency and foster innovation in modern manufacturing environments.

Future Trends: Innovations in Hand Press Technology for Optimal Performance

In the ever-evolving landscape of manufacturing, hand press machines are embracing innovative technologies that enhance their efficiency and effectiveness. The future trends in hand press technology highlight the integration of smart features, such as IoT connectivity and automation, which can streamline the production process. By equipping machines with sensors, operators can gather real-time data, monitor performance, and predict maintenance needs, ultimately reducing downtime and boosting productivity.

To maximize the performance of hand press machines, one effective tip is to invest in ergonomic designs. Comfortable setups not only enhance user experience but also minimize fatigue, allowing operators to maintain focus and efficiency throughout the production cycle. Additionally, regular training sessions on the latest technologies and best practices will empower employees, ensuring they can effectively utilize the full capabilities of these advanced machines.

Another trend shaping the future is the development of modular hand press systems. These versatile setups allow manufacturers to easily reconfigure their production lines based on changing demands. Implementing a modular system can significantly reduce setup times and increase flexibility, ultimately leading to more efficient operations.

Related Posts

-

Unlocking Global Trade with Best Hydraulic Metal Shear Machine Import and Export Certification Guide

-

The Definitive Handbook to Sheet Metal Press Machines: Mastering Efficiency and Innovation

-

Unwavering Quality from Trusted Chinese Manufacturers Best Shear Press Solutions

-

Achieving Excellence in Manufacturing Standards with the Best Industrial Press Techniques

-

The Future of Precision Engineering with Best Press Brake Technology

-

Exploring the Unique Features and Applications of Various Best Press Machine Types