Maximize Productivity: How Our After-Sales Services and Low Maintenance Costs Elevate Your CNC Hydraulic Press Brake Experience

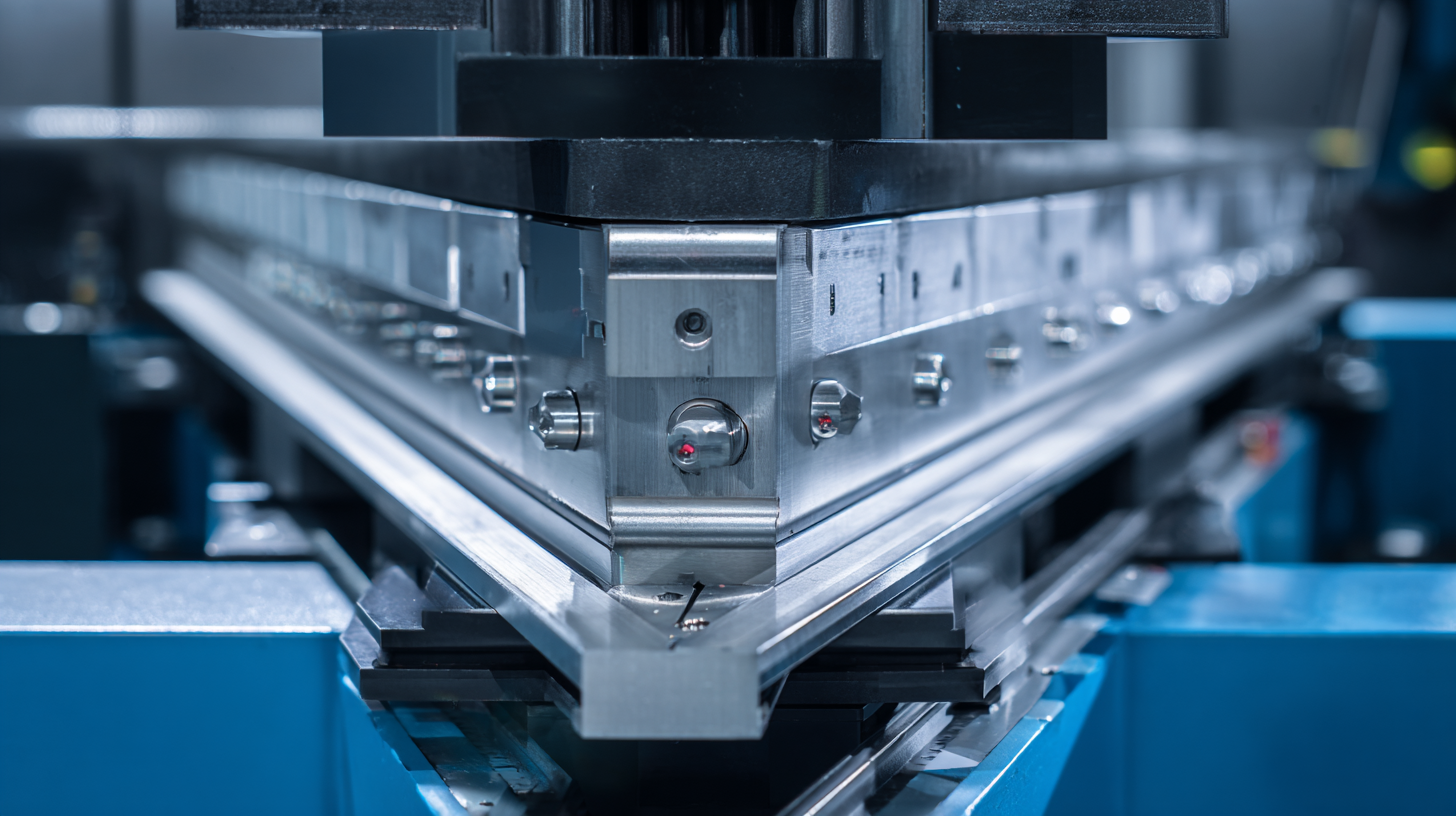

In today’s fast-paced manufacturing environment, maximizing productivity is crucial for maintaining a competitive edge, and nothing exemplifies this better than the use of a CNC hydraulic press brake. These sophisticated machines not only streamline the bending process but also require minimal maintenance to keep operations running smoothly. Our after-sales services are designed to further elevate your experience by ensuring that any potential issues are promptly addressed, thereby reducing downtime and enhancing overall efficiency. Coupled with low maintenance costs, the benefits of investing in a CNC hydraulic press brake extend far beyond initial purchase. This blog will delve into how these combined factors create a seamless workflow, boost productivity, and ultimately contribute to the success of your manufacturing operations.

Maximize CNC Hydraulic Press Brake Efficiency with Reliable After-Sales Support

When it comes to maximizing the efficiency of CNC hydraulic press brakes, reliable after-sales support plays a crucial role. According to a recent industry report, companies that utilize dedicated after-sales services see a 30% increase in operational uptime. This highlights the direct correlation between effective support systems and machine performance. Providing timely maintenance and assistance ensures that these complex machines run smoothly, addressing potential issues before they escalate into costly downtime.

Tips: Regularly schedule maintenance checks and ensure that your after-sales support team is easily accessible. Keeping a log of all service interactions can also help tailor your service requirements based on historical data.

Moreover, low maintenance costs directly influence the total cost of ownership for CNC hydraulic press brakes. A study by Manufacturing Insights indicated that businesses with proactive maintenance strategies can save up to 25% in maintenance expenses annually. Investing in machines that come with competitive after-sales services often leads to not only higher efficiency but also a lower long-term expenditure.

Tips: Evaluate your CNC machine investment against its support service offerings. Consider how a well-rounded after-sales package can enhance your productivity while minimizing hidden costs.

Understanding the Cost-Benefit Analysis of Low Maintenance for CNC Equipment

In a rapidly evolving industrial landscape, understanding the cost-benefit analysis of low maintenance for CNC equipment can significantly enhance productivity. The global CNC machine market is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, showcasing an impressive CAGR of 9.9%. This growth is driven largely by advancements in technology, which not only improve processing speed but also reduce the frequency and costs associated with maintenance. Efficient after-sales services further contribute to this advantage, ensuring that CNC machines operate at peak performance with minimal downtime.

Tips for maximizing the benefits of low maintenance include investing in high-quality CNC hydraulic press brakes that come equipped with advanced monitoring systems. For instance, predictive maintenance technologies can identify potential issues before they escalate, allowing for timely interventions that keep operations running smoothly. Additionally, regular training for operators on optimal machine usage can reduce wear and tear, prolonging the life of the equipment and keeping maintenance costs low.

With the CNC plasma cutting market projected to reach $673.2 million by 2024, enhancing operational efficiency through low maintenance and effective after-sales support is crucial. By integrating these practices, manufacturers can not only reduce costs but also stay competitive in a dynamic market.

Key Industry Statistics Highlighting the Impact of After-Sales Services on Productivity

After-sales services play a crucial role in maximizing the productivity of CNC hydraulic press brakes. According to a recent report by the Association for Manufacturing Technology, companies that invest in robust after-sales support see a productivity increase of up to 20%. This can largely be attributed to reduced downtime, as timely maintenance and expert assistance ensure that machines are operating at peak performance.

To further enhance your productivity, consider implementing a structured maintenance schedule. Regular checks can prevent unexpected breakdowns and extend the lifespan of your equipment. For instance, routine inspections and minor repairs typically cost 30% less than emergency services, highlighting the importance of proactive maintenance in managing operational costs.

Additionally, training your staff on effective machine operation can significantly reduce errors and increase output. A study by the National Institute of Standards and Technology found that organizations with well-trained operators can improve production efficiency by up to 25%. By focusing on both after-sales support and employee training, businesses can create a more efficient manufacturing environment that is both cost-effective and productive.

Best Practices for Maximizing CNC Machine Uptime and Performance

Maximizing CNC machine uptime and performance is essential for any manufacturing operation aiming to increase productivity and profitability. By implementing best practices such as regular maintenance and utilizing advanced analytics, manufacturers can dramatically enhance the efficiency of their CNC hydraulic press brakes. By actively monitoring machine performance and identifying potential issues before they escalate, businesses can reduce downtime and ensure that their operations run smoothly.

Incorporating machine learning models into production processes can provide valuable insights, enabling manufacturers to optimize their machines' performance. Analyzing data from various sources allows shops to benchmark against industry standards and continuously refine their workflows. For instance, understanding how different operational metrics correlate with machine uptime can inform decisions that lead to improved productivity.

Ultimately, by focusing on best practices and leveraging data-driven strategies, manufacturers can fully unlock the potential of their CNC machines, leading to enhanced competitiveness in the market.

The Role of Predictive Maintenance in Reducing Total Operating Costs for CNC Press Brakes

Predictive maintenance plays a crucial role in enhancing the efficiency and longevity of CNC press brakes. By leveraging advanced analytics and monitoring technologies, manufacturers can anticipate potential issues before they escalate into costly breakdowns. This proactive approach not only minimizes downtime but also significantly reduces total operating costs, making your investment more worthwhile.

**Tip:** Regularly monitor the performance metrics of your press brake. This data can help identify patterns and predict when maintenance may be required, allowing for timely interventions.

Implementing a predictive maintenance strategy means that your CNC hydraulic press brake can operate at peak efficiency. By addressing maintenance needs based on actual usage and wear, rather than adhering to a rigid schedule, companies can ensure that machinery performs optimally. Furthermore, this focused maintenance strategy extends the life cycle of your equipment and boosts overall productivity.

**Tip:** Integrate a maintenance management system that tracks not just machine performance but also maintenance history. This ensures you have comprehensive insights for better decision-making.

By investing in predictive maintenance, users enjoy fewer disruptions in production schedules, leading to improved operational efficiency. This cost-effective approach not only safeguards your machinery but also enhances your ability to meet market demands swiftly.