Mastering Sheet Metal Fabrication: Essential Tips for Choosing the Right Press Brake

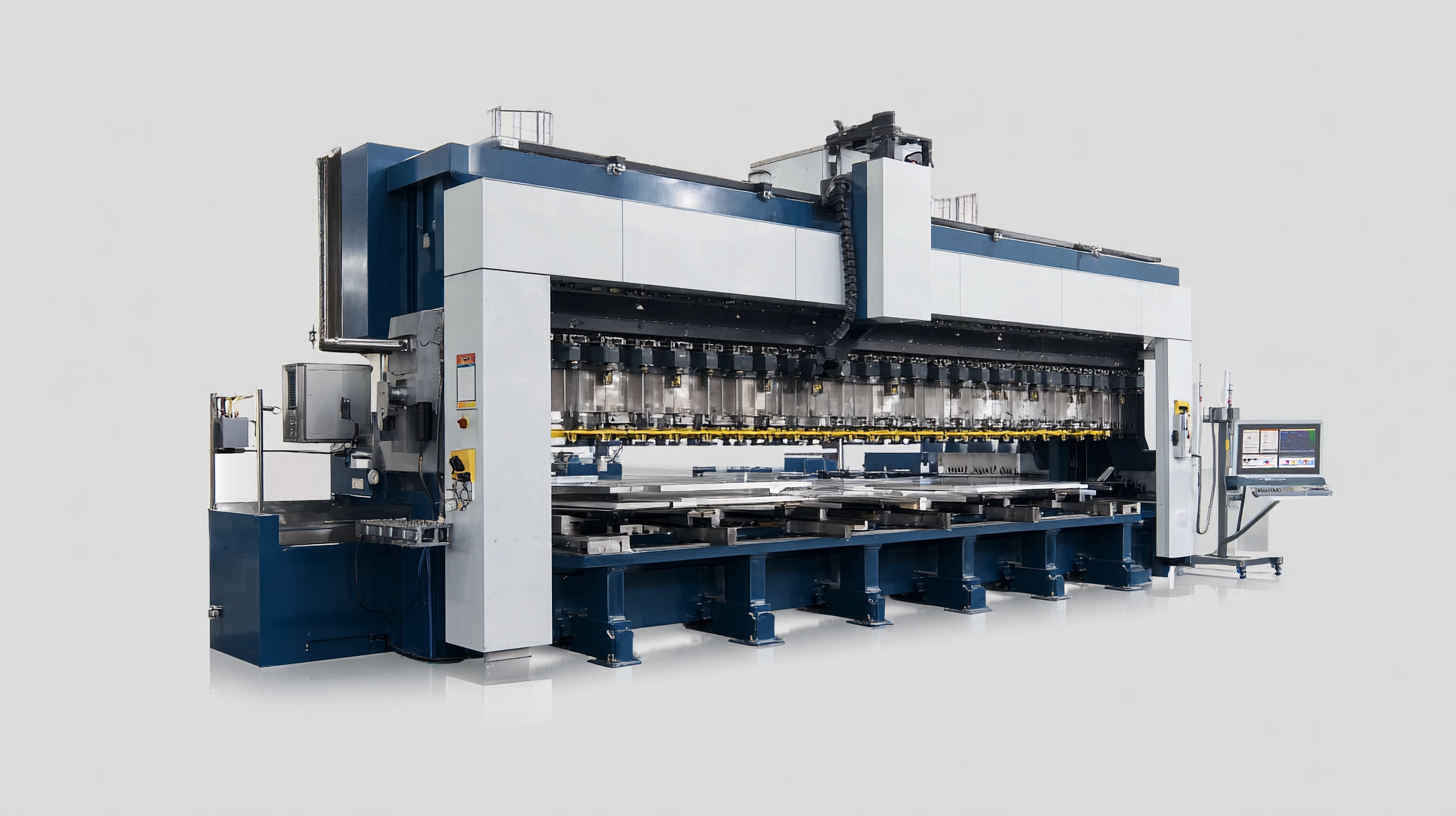

In the world of manufacturing and metalworking, mastering the art of sheet metal fabrication is essential for achieving precision and efficiency in your projects. One of the most crucial tools in this process is the sheet metal press brake. This machine allows fabricators to bend, shape, and manipulate sheet metal with incredible accuracy, enabling the creation of complex designs and structures.

Choosing the right sheet metal press brake can significantly impact the quality of your work, as well as the overall productivity of your operations. With various options available on the market, it becomes imperative to understand the essential features, types, and capabilities of these machines. This article aims to provide key insights and tips for selecting the ideal press brake that caters to your specific fabrication needs. Whether you are a seasoned professional or a newcomer in the field, equipping yourself with this knowledge will ensure that your metalworking projects are not only successful but also efficient and cost-effective.

Understanding Different Types of Press Brakes for Sheet Metal Fabrication

When selecting the right press brake for sheet metal fabrication, understanding the different types available is crucial. Modern press brakes offer advanced features that significantly enhance productivity and precision. For instance, computer numerical control (CNC) press brakes enable operators to automate bending processes, reducing setup times and minimizing errors. According to industry reports, shops utilizing CNC technology can achieve up to a 30% increase in efficiency, allowing for quicker turnaround times on projects.

Furthermore, choosing between a traditional press brake and a panel bender can impact part quality and operational flow. Experienced operators emphasize that while press brakes are well-suited for certain applications, transition to panel benders can lead to different bending characteristics, potentially elongating parts in unforeseen ways. A study highlighted that transitioning processes without proper training can result in up to a 20% increase in reject rates, affecting overall production quality. Therefore, training staff in both equipment usage and process control is essential for maintaining operational integrity in the metal fabrication shop. Ensuring that skilled operators are engaged in these transitions not only preserves efficiency but also enhances the overall quality of the fabrication output.

Key Specifications to Consider When Selecting a Press Brake

When selecting a press brake for sheet metal fabrication, several key specifications warrant consideration to ensure optimal performance and efficiency. One crucial aspect is the brake's tonnage, which directly impacts its ability to bend materials of varying thicknesses. According to a report by the Fabricators & Manufacturers Association (FMA), a press brake should generally have a tonnage capacity of 1 to 1.5 times the material thickness in inches multiplied by the length of the machine. For instance, a 10-foot press brake for bending 0.25-inch thick steel would require between 60 to 75 tons of tonnage.

Another vital specification is the bending accuracy, often expressed in terms of the ram's repeatability and angle control. Industry studies show that modern CNC press brakes can achieve an accuracy of ±0.002 inches, significantly improving the consistency of production runs. Furthermore, considering the press brake’s tooling compatibility and adaptability is essential for handling diverse projects. By choosing a machine capable of using various punch and die combinations, fabricators can enhance their operational versatility and reduce downtime caused by tooling changes. Ensuring these specifications align with your production needs will ultimately lead to improved productivity and product quality in sheet metal fabrication.

Tips for Evaluating Press Brake Manufacturers and Brands

When evaluating press brake manufacturers and brands, the first step is to consider their reputation in the industry. Look for companies with a proven track record of reliability and innovation. Research customer testimonials and case studies to gauge user experiences. A manufacturer’s longevity in the market can also be a strong indicator of quality. Companies that have been in business for many years are likely to understand the complexities of metal fabrication and continuously improve their products.

Additionally, it is essential to assess the technical support and services offered by the manufacturer. A reliable press brake brand should provide comprehensive training, accessible customer service, and readily available replacement parts. This commitment to customer support not only enhances the lifespan of the equipment but also ensures that any operational challenges can be addressed promptly. By prioritizing manufacturers that invest in their clients through robust service options, you can ensure a smoother and more efficient fabrication process.

Maintenance and Safety Practices for Optimal Press Brake Performance

When it comes to ensuring optimal performance of a press brake, maintenance and safety practices are paramount. According to the Fabricators & Manufacturers Association (FMA), about 23% of all workplace injuries in manufacturing can be attributed to improper use of machinery, including press brakes. To mitigate these risks, regular maintenance checks should be scheduled to inspect essential components such as hydraulic systems, tooling, and safety features.

Tip: Always adhere to the manufacturer's guidelines for lubrication and inspection intervals. Keeping a detailed maintenance log can help track service history and identify potential issues before they lead to costly downtime.

In addition to maintenance, fostering a culture of safety is crucial. Training operators on the best safety practices, including proper machine operation and emergency procedures, significantly reduces the risk of accidents. The Occupational Safety and Health Administration (OSHA) reports that well-trained employees are 40% less likely to suffer workplace injuries.

Tip: Implement a regular training program and conduct safety drills to reinforce best practices among operators. Ensuring that all staff are equipped with personal protective equipment (PPE) is also essential to safeguard against potential hazards.

How to Choose the Right Tools and Accessories for Your Press Brake

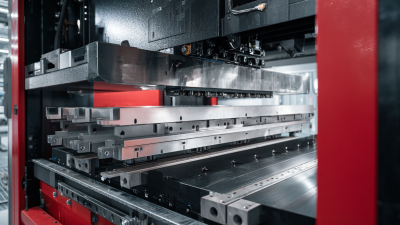

When selecting the right tools and accessories for your press brake, it's essential to consider the specific requirements of your metal fabrication projects. The choice of tooling can significantly influence both the accuracy and efficiency of your bending operations. For instance, using the correct punch and die setup is crucial for achieving the desired bend angle and radius. Investing in high-quality tools, such as segmented dies, allows for greater flexibility in processing various sheet metal thicknesses and dimensions.

In addition to the tooling, other accessories play a vital role in maximizing the performance of your press brake. Back gauges, for example, are indispensable for ensuring precise measurements and repeatability across multiple bends. Clamping systems and material handling devices also enhance safety and productivity by streamlining the workflow. When equipping your press brake, make sure to assess the compatibility of these accessories with your existing equipment and your future project needs, ultimately leading to improved outcomes in your sheet metal fabrication endeavors.

Mastering Sheet Metal Fabrication: Essential Tips for Choosing the Right Press Brake

| Criteria | Description | Key Factors |

|---|---|---|

| Type of Press Brake | Determine whether a mechanical or hydraulic press brake is best for your application. | Power, precision, and available space |

| Bending Capacity | Evaluate the material thickness and width you will be working with. | Material type, thickness, and desired bend angle |

| Tooling Options | Select appropriate dies and punches based on your needs. | Type of bends and material used |

| Control Systems | Choose between manual, programmable, or CNC controls for your press brake. | Ease of use and required precision |

| Safety Features | Ensure the press brake has necessary safety guards and emergency stops. | Compliance with safety standards |

| Budget | Consider the total cost, including purchase, setup, and maintenance. | Initial investment and long-term operating costs |

Related Posts

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology

-

Unlocking Precision: The Best Press Brake Machines from China’s Premier Manufacturing Factory

-

Craftsmanship Redefined Chinese Manufacturing Delivering the Best Press Brake Solutions Worldwide

-

Ultimate Guide to Mastering Metal Press Brake Operations for Precision Fabrication

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

Innovative Solutions for Efficient Metal Forming with the Best Small Press Brake