Mastering the Best CNC Press Brake Selection Process for Global Buyers

The growing demand for precision fabrication in various industries has made the CNC press brake an essential tool for manufacturers worldwide. According to a recent report by ResearchAndMarkets, the global CNC press brake market is expected to reach $5.42 billion by 2026, driven by advancements in technology and the increasing need for automation in metalworking processes. This surge underscores the importance of selecting the right CNC press brake that aligns with production requirements and quality standards. As global buyers look to capitalize on these trends, understanding the features and specifications that distinguish one machine from another becomes critical. With world-class Chinese manufacturers leading the charge in providing exceptional manufacturing solutions, mastering the selection process for CNC press brakes not only relates to performance but also involves evaluating supplier capabilities, machine durability, and technological innovations.

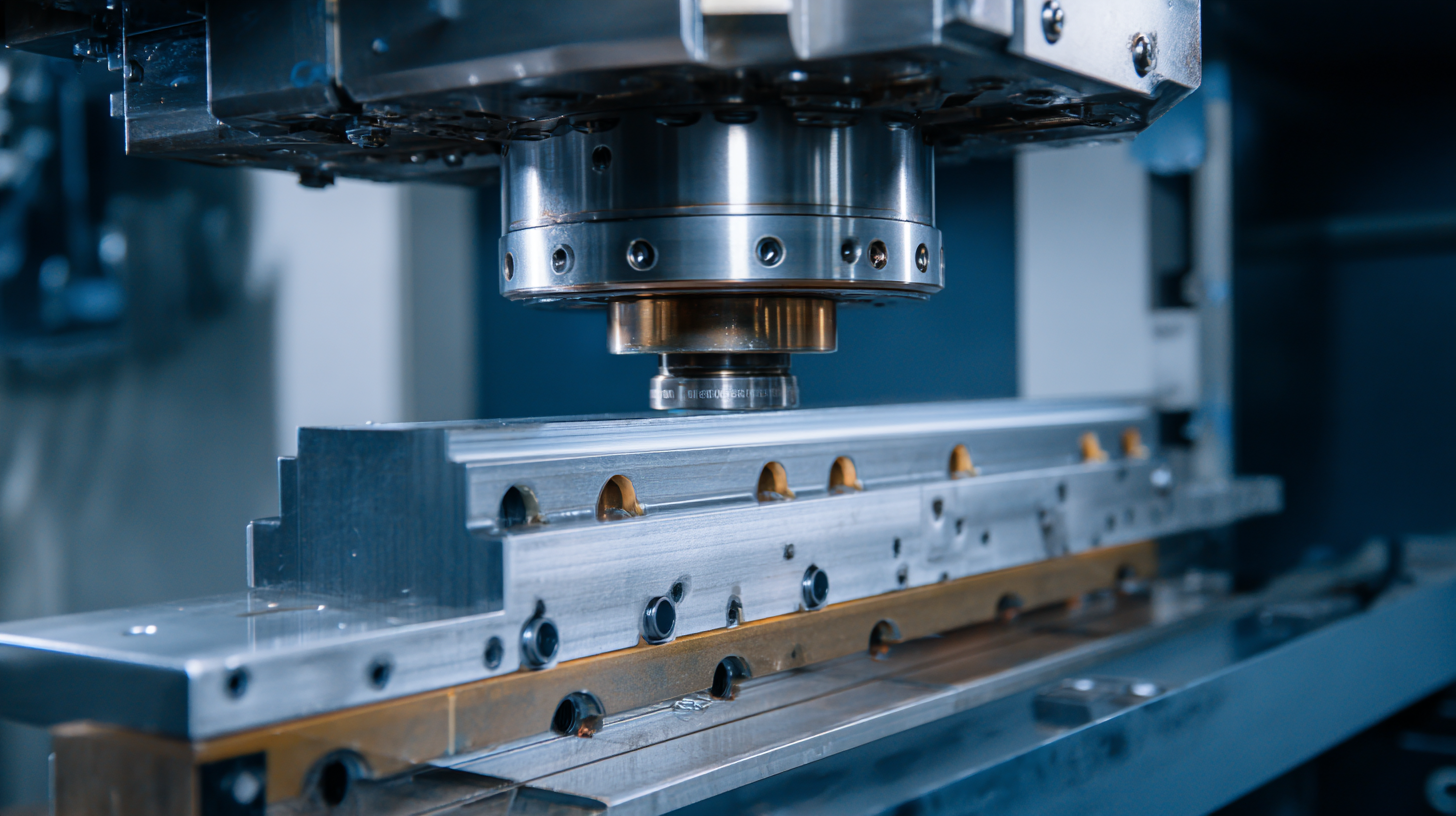

Understanding the Essential Factors for CNC Press Brake Selection

When selecting a CNC press brake, global buyers must understand several essential factors that can significantly impact their purchasing decision. Firstly, the bending capacity and throat depth should align with the specific types of materials and thicknesses that will be processed. This ensures not only operational efficiency but also the ability to achieve precise bends without compromising the integrity of the material. Furthermore, buyers should consider the type of controls available, as modern CNC systems offer enhanced programming options that can streamline production and reduce the risk of human error.

Another critical factor is the construction quality of the press brake. Buyers must assess the machine's frame rigidity and precision of parts, as these elements are crucial for maintaining accuracy during operation. Additionally, features such as automatic crowning and back gauge systems can enhance the overall performance, providing greater flexibility in handling various tasks. Investing time in evaluating these essential factors will enable buyers to select a CNC press brake that not only meets their immediate production needs but also offers long-term reliability and efficiency in manufacturing processes.

Evaluating Different Types of CNC Press Brakes for Your Needs

Selecting the right CNC press brake is crucial for optimizing your manufacturing processes. With various types available, each designed for specific applications, it's important to evaluate your needs carefully. You might consider factors such as bending capacity, material thickness, and the overall complexity of your projects. Understanding these requirements will assist in narrowing down your options.

Tips: Always assess the technological features of different CNC press brakes. Look for models that offer advanced controls and automation, which can enhance precision and reduce operator error. Additionally, consider the availability of support services and spare parts in your region to ensure long-term operational efficiency.

Another essential aspect is the machine’s versatility. Some CNC press brakes are better suited for high production runs, while others excel in one-off projects or custom work. Gauge how flexible your chosen machine needs to be based on your future production demands.

Tips: Prioritize machines that offer tool-changing capabilities, as this can dramatically increase efficiency when transitioning between different tasks. Also, reading customer reviews can provide insights into reliability and performance, helping you make an informed decision.

Comparative Analysis: Traditional vs. Modern CNC Press Brakes

When it comes to selecting a CNC press brake, understanding the key differences between traditional and modern models is crucial for global buyers. Traditional CNC press brakes often come with mechanical controls that require more manual intervention and offer limited flexibility in terms of programming. These machines, while reliable, may fall short in terms of speed and precision, leading to increased cycle times and potential production bottlenecks. Operators frequently need to possess advanced technical knowledge to optimize their usage, which can be a barrier for less experienced teams.

In contrast, modern CNC press brakes leverage advanced automation and digital controls, significantly enhancing operational efficiency. With features like adaptive technology, these press brakes can automatically adjust to variances in material thickness and type, providing not only improved accuracy but also reduced waste. Additionally, user-friendly interfaces and programmable options enable even those with minimal experience to achieve high-quality results. Global buyers must consider these advancements when making their selection, as the capabilities of modern machines can lead to substantial productivity gains in the long run.

Key Features to Look for in a High-Quality CNC Press Brake

When selecting a high-quality CNC press brake, several key features should be prioritized to ensure optimal performance and durability. One of the most crucial aspects is the machine's precision and accuracy. According to a report by IBISWorld, the global CNC machine tools market is expected to grow at a CAGR of 6% through 2026, reflecting the increasing demand for precision-engineered machining solutions. Features such as advanced servo systems and high-quality tooling can significantly enhance a press brake's capability to produce precise bends with minimal tolerance, making it indispensable for manufacturers aiming to meet stringent quality standards.

Another critical factor is the machine's tonnage and bending length. Industry standards suggest that the choice of tonnage should correlate with the thickness of the material being processed; a general guideline is about 1 ton of pressure per 1 mm of thickness for mild steels. Furthermore, the bending length should accommodate the largest component size you intend to work with. According to Technavio, the global press brake market is projected to reach USD 3.9 billion by 2025, which underscores the need for versatile machines that can handle a wide range of materials and sizes. Buyers should also consider the ease of use provided by modern CNC controls, as user-friendly interfaces can reduce training time and enhance operational efficiency.

Top Mistakes to Avoid When Choosing a CNC Press Brake

Choosing the right CNC press brake is crucial for global buyers looking to enhance their manufacturing capabilities. However, there are common mistakes that can lead to suboptimal decisions. One significant mistake is neglecting to consider the specific needs of your production environment. It's essential to evaluate factors such as the types of materials you will be bending, the thickness of the materials, and the required bend precision. Without a clear understanding of these requirements, you may end up with a machine that does not meet your operational demands.

Another common pitfall is overlooking the importance of technology integration. As the CNC machine market is projected to grow significantly, with a compound annual growth rate of 9.9% from 2025 to 2032, buyers often find themselves drawn to the latest advancements. However, ensuring that the press brake can seamlessly integrate with your existing systems is vital. Failing to do so can lead to inefficiencies and increased operational costs. Careful consideration of technology compatibility is essential for making a sound investment in the future of your manufacturing process.