Comprehensive Manual Press Machine Guide: Everything You Need to Know for Optimal Use

In the ever-evolving landscape of manufacturing, the manual press machine has emerged as a cornerstone for efficient production processes, particularly in small to medium-sized enterprises. According to a recent report by the International Federation of Robotics, the manual press machine market has seen a notable growth rate of 6% annually, reflecting its vital role in the industry. This versatile equipment not only enhances productivity but also ensures precision in operations, making it an invaluable asset for operators and businesses alike. However, optimal use of manual press machines requires a deep understanding of their functionalities and best practices. In this comprehensive guide, we will explore everything you need to know—from essential tips to advanced techniques—to maximize the efficiency and longevity of your manual press machine, ensuring your operations remain competitive and effective in today’s demanding market.

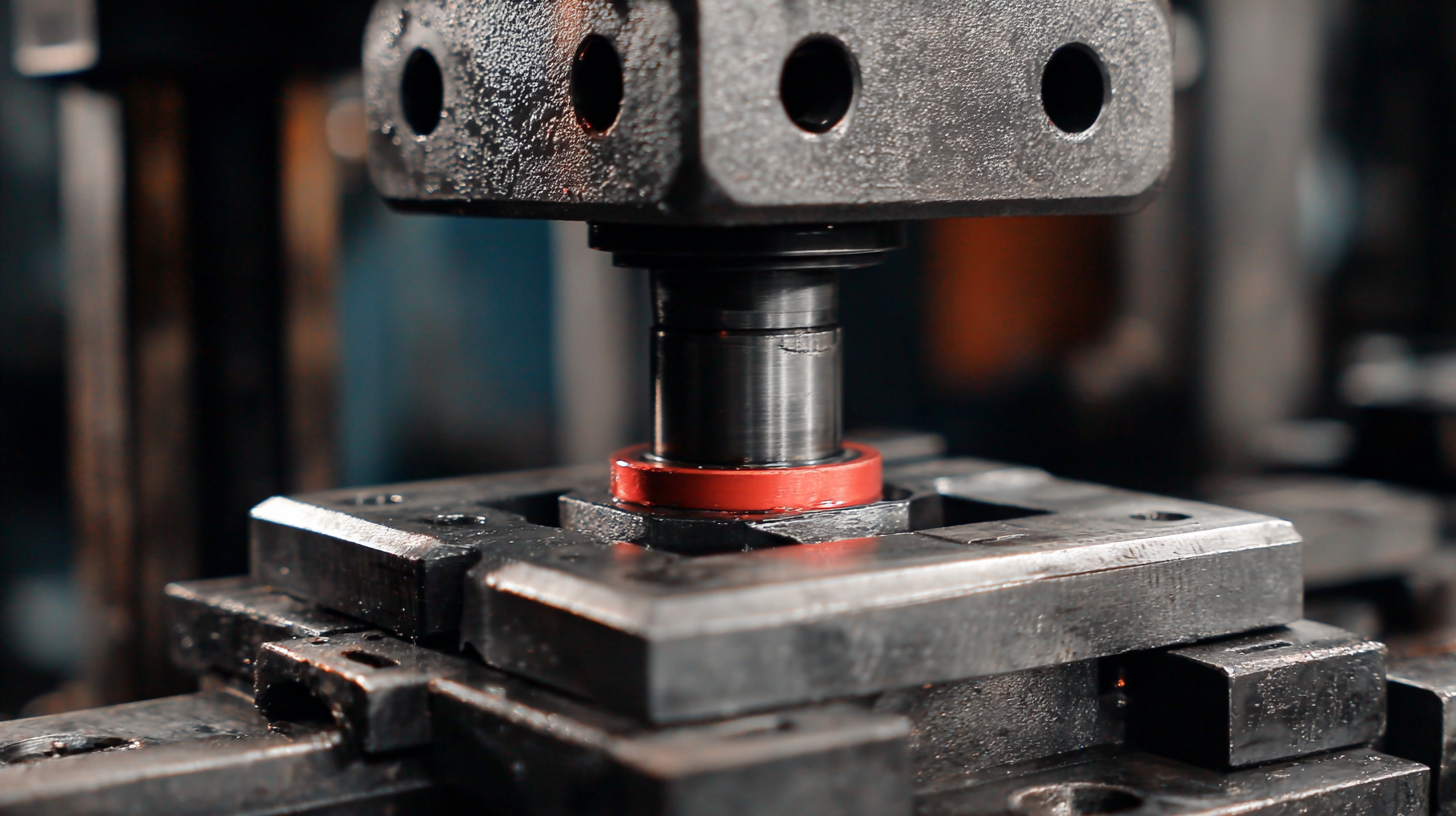

Understanding the Basics of Manual Press Machines and Their Key Components

Manual press machines are essential tools in various industries, offering precision and control for a range of applications. To effectively use these machines, it's crucial to understand their key components, which typically include the frame, the ram, and the handle. The frame provides stability and support, while the ram applies pressure to mold or shape materials. The handle allows for manual operation, giving the user the leverage needed to exert force accurately.

When using a manual press machine, ensure that you maintain it properly. Regular inspection of the components for wear and tear can prevent malfunction and enhance the machine’s lifespan. Additionally, familiarize yourself with the operation manual to understand specific requirements and safety procedures for your particular model.

Tip: Always use the appropriate force for the material you are working with to avoid damage and ensure effectiveness. Furthermore, consider the workspace arrangement; a well-organized setup can greatly improve efficiency and safety while operating the machine.

Essential Safety Protocols: Ensuring Safe Operation of Manual Press Machines

When operating manual press machines, safety should always be the top priority. First and foremost, operators should wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and steel-toed boots. This basic gear helps mitigate the risk of injury from potential accidents. Additionally, ensuring that the work area is clean and free of distractions can reduce the likelihood of mishaps while handling the machine.

Moreover, it is essential to familiarize oneself with the equipment's operating manual before use. Understanding the specific safety features and emergency procedures can make a significant difference in preventing accidents. Always perform a thorough check of the machine before starting any work. Look for worn or damaged parts and ensure that all safety guards are in place. Operators should also be mindful of their hand placement during operation, keeping fingers clear of pinch points to avoid severe injuries. By adhering to these essential safety protocols, you can enjoy a safer, more efficient experience with manual press machines.

Top 5 Maintenance Tips for Maximizing Efficiency and Longevity of Your Press Machine

When it comes to maintaining the efficiency and longevity of press machines, regular upkeep is essential. According to a report by the Association of Manufacturing Technology, proper maintenance can reduce downtime by up to 30%, significantly impacting production efficiency. To achieve optimal performance, it is crucial to adopt a regular cleaning schedule. Dust and debris can accumulate in the machine’s components, leading to increased wear and tear. A bi-weekly cleaning routine can prolong the life of critical elements, ensuring uninterrupted operations.

Additionally, lubrication plays a vital role in minimizing friction and heat generation, which can otherwise damage machinery. The Machinery Lubrication magazine emphasizes that using the right lubricant can enhance machine life by 50%. It's advisable to follow the manufacturer’s guidelines for lubrication intervals and types. Monitoring the fluid levels and replacing worn lubricants can significantly impact the machine's performance and reliability. Adopting these maintenance tips not only maximizes the efficiency of the press machine but also helps in achieving a high return on investment over time.

Press Machine Efficiency and Maintenance Analysis

This chart illustrates the impact of different maintenance frequencies on the overall efficiency of a press machine. Regular daily maintenance yields the highest efficiency, while annual maintenance shows a significant drop, highlighting the importance of consistent care.

Common Troubleshooting Techniques for Manual Press Machine Issues

When using a manual press machine, encountering issues can be a frustrating experience. However, understanding some common troubleshooting techniques can help you resolve these problems quickly and efficiently. One of the first steps in troubleshooting is to identify the source of the issue. Common problems include uneven pressure, jammed materials, or misalignment of the press. Inspecting the machine for any visible signs of wear or damage can often reveal the underlying cause.

Another effective technique is to check the adjustments and settings of the machine. Ensure that the pressure is properly calibrated and that the materials are correctly positioned. If you notice that the press is not applying uniform pressure, it may be necessary to make adjustments to the pressure settings or to check the alignment of the die.

Regular maintenance is also crucial; lubricating moving parts and cleaning the machine can prevent many common issues from arising in the first place. By being proactive and employing these troubleshooting techniques, you can ensure optimal performance from your manual press machine.

Performance Metrics: How to Measure the Effectiveness of Your Manual Press Operations

When it comes to optimizing manual press operations, establishing effective performance metrics is crucial. Performance metrics help businesses identify areas for improvement, streamline processes, and enhance overall productivity. Key indicators such as cycle time, defect rates, and operator efficiency can provide valuable insights into the effectiveness of manual press usage. By systematically tracking these metrics, operators can make informed decisions that lead to better outcomes.

**Tips for Measuring Effectiveness:**

1. Track Cycle Time: Monitor the time taken for each cycle to identify bottlenecks in the process. Reducing cycle time can lead to increased throughput.

2. Analyze Defect Rates: Regularly evaluate the quality of output. Keeping a close watch on defect rates allows for immediate adjustments to maintain high standards.

3. Assess Operator Performance: Encourage operators to self-assess their efficiency and provide feedback. Empowering them in this way fosters better practices and enhances overall team performance.

By implementing these measures, companies can leverage data to refine manual press operations, ensuring optimal use and maximizing performance.

Related Posts

-

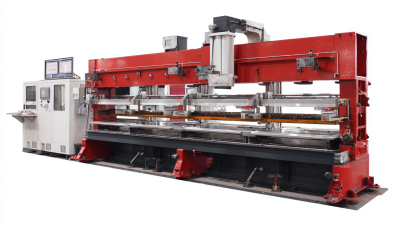

15 Reasons Why the Best Press Machine Can Transform Your Production Process

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

Solutions for Optimizing Efficiency with the Best Manual Press Machine

-

Exploring the Unique Features and Applications of Various Best Press Machine Types

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

Maximize Productivity: How Our After-Sales Services and Low Maintenance Costs Elevate Your CNC Hydraulic Press Brake Experience