What is the Importance of Manual Press Machines in Modern Manufacturing

In the evolving landscape of modern manufacturing, the manual press machine stands as a crucial component that marries traditional craftsmanship with contemporary production demands. According to a report by ResearchAndMarkets, the global manufacturing market is projected to reach $5.7 trillion by 2026, emphasizing the need for efficient and flexible production methods. Manual press machines, which allow for hands-on control and precision, play a vital role in industries that require fine-tuning and customization, such as automotive and electronics. Furthermore, a study by the National Association of Manufacturers (NAM) reveals that 85% of manufacturers believe machinery upgrades are essential to maintaining competitiveness. With the ability to adapt to various materials and production techniques, manual press machines not only enhance productivity but also ensure quality in output, making them indispensable in today's manufacturing ecosystem.

The Role of Manual Press Machines in Enhancing Precision in Manufacturing Processes

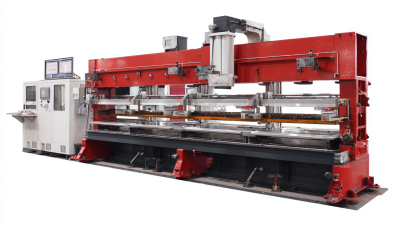

Manual press machines play a crucial role in enhancing precision within modern manufacturing processes. Unlike automated systems, manual presses allow operators to have direct control over each step, enabling them to make real-time adjustments that significantly improve the accuracy of dimensional measurements and geometric tolerances. This hands-on approach is particularly beneficial during the finishing process of large-size and high-precision components, where minute discrepancies can lead to substantial quality issues.

Tips: When operating manual press machines, it is essential to maintain an ergonomic workspace to reduce the risk of injury. Positioning tools and materials within easy reach can enhance efficiency and precision. Additionally, conducting regular maintenance checks on the machines ensures consistent performance and accuracy, which is vital when integrating digital technologies into the manufacturing process.

The advancements in digital twin technology also complement manual presses by providing a framework for real-time data analysis. This integration allows manufacturers to visualize and control their processes more effectively, tackling challenges related to data flow management. By leveraging such technologies, operations can pivot towards a more precise and quality-centric approach, aligning with the best practices established in lean manufacturing.

The Importance of Manual Press Machines in Modern Manufacturing

This chart illustrates the significance of manual press machines in enhancing precision across various manufacturing process dimensions such as production speed, cost efficiency, and accuracy levels.

Impact of Manual Press Machines on Production Efficiency and Cost-Effectiveness

The significance of manual press machines in modern manufacturing cannot be overstated, particularly when considering their impact on production efficiency and cost-effectiveness. As the global metal forming tools market is set to expand significantly, reaching an estimated $51.67 billion by 2032, it’s clear that the demand for efficient production methods is growing. Manual press machines play a pivotal role in this landscape by allowing manufacturers to carry out precise metal forming processes without the high initial investment required for automated systems.

Moreover, the adoption of manual press machines enhances production flexibility, enabling manufacturers to respond swiftly to changing market demands. These machines require less maintenance and operational oversight compared to automated alternatives, which reduces overall operational costs. This makes manual press machines an appealing option for small to medium-sized enterprises looking to improve their manufacturing capabilities without incurring substantial financial burdens.

As advancements in lean manufacturing continue to emerge, integrating manual press machines can further streamline production processes, ensuring manufacturers remain competitive in a rapidly evolving market.

Challenges Faced by Manufacturers Utilizing Manual Press Technology Today

In the modern manufacturing landscape, manual press machines hold a unique yet challenging position. One of the primary struggles faced by manufacturers utilizing this technology today is the need for consistent quality control. Manual presses rely heavily on operator skill and experience, which can lead to variations in product precision. As manufacturers strive for higher standards and faster production rates, this inconsistency can become a notable bottleneck. Implementing rigorous training and quality assurance protocols is essential to mitigate these issues, but they demand time and resources that not all manufacturers can easily afford.

Another challenge is the integration of manual press machines within increasingly automated environments. As factories move toward automation, the role of manual machines can often conflict with advanced technologies like CNC and robotic systems. Manufacturers must find effective ways to either modernize their manual presses or determine how to best leverage them in conjunction with automated processes. This balancing act requires strategic planning and can result in significant operational hurdles, forcing manufacturers to rethink their production strategies and workflows to ensure efficiency while still utilizing the valuable capabilities of manual presses.

Comparative Analysis: Manual vs. Automated Press Machines in Manufacturing

The debate between manual and automated press machines continues to shape the landscape of modern manufacturing. While automated press machines boast enhanced speed and precision, manual press machines hold considerable value, particularly for small to medium-sized enterprises. According to a report by Grand View Research, the global manual press machine market is expected to reach approximately $2 billion by 2028, highlighting its enduring relevance in niche manufacturing sectors. Manual presses provide flexibility, allowing operators to make quick adjustments and cater to custom orders, which can be a significant advantage in today’s fast-paced market.

When considering which type of press machine is best for your operation, it’s essential to evaluate your production needs. Automated machines can achieve up to 90% efficiency for high-volume tasks, but they may come with higher upfront costs and maintenance challenges. Conversely, manual machines often cost less and require fewer resources, making them ideal for businesses where production scales are variable.

Tips: Always conduct a thorough cost-benefit analysis when investing in press machines. If your production includes intricate, small-batch parts, manual presses may offer the precision needed without the complexities of automation. Additionally, consider the skill level of your workforce; investing in training for manual press operation can significantly enhance productivity and reduce errors.

Industry Trends: The Future of Manual Press Machines in Smart Manufacturing Systems

In the rapidly evolving landscape of smart manufacturing, manual press machines are undergoing a significant transformation, becoming increasingly essential in streamlined production processes. As industries embrace automation and digital technologies, the integration of manual press machines into smart systems allows for enhanced flexibility and operational efficiency. These machines can be easily adapted to various tasks, making them valuable for small-batch production or customized manufacturing needs, where agility is paramount.

Moreover, the future of manual press machines in smart manufacturing lies in their ability to complement automated systems. While automation handles high-volume tasks, manual presses can offer precision and craftsmanship for intricate projects that require human oversight. This hybrid approach not only optimizes productivity but also preserves the artisanal skills that are vital in certain industries. As manufacturers continue to seek balance between automation and human expertise, the role of manual press machines will be pivotal in developing a more resilient and adaptive manufacturing ecosystem.

What is the Importance of Manual Press Machines in Modern Manufacturing

| Dimension | Details |

|---|---|

| Application Areas | Automotive, Aerospace, Electronics, Metalworking |

| Key Benefits | High Precision, Flexibility, Cost-Effectiveness, Space Efficiency |

| Current Trends | Integration with IoT, Automation, Enhanced User Interfaces |

| Future Prospects | Adaptation to Smart Factories, Improved Energy Efficiency, Advanced Manufacturing Techniques |

| Challenges | Workforce Training, Integration Costs, Maintenance of Equipment |

Related Posts

-

Solutions for Optimizing Efficiency with the Best Manual Press Machine

-

Maximize Productivity: How Our After-Sales Services and Low Maintenance Costs Elevate Your CNC Hydraulic Press Brake Experience

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

The Ultimate Checklist for Sourcing the Best Steel Press Machine for Your Manufacturing Needs

-

Unwavering Quality from Trusted Chinese Manufacturers Best Shear Press Solutions