How to Use a Hydraulic Metal Brake Press for Effective Metal Forming

The hydraulic metal brake press is an invaluable tool in the metalworking industry, offering precision and versatility for various metal forming applications. This powerful machine utilizes hydraulic force to bend and shape metal sheets with accuracy and efficiency, making it a preferred choice for fabricators and metalworkers. Understanding how to effectively operate a hydraulic metal brake press is crucial for achieving high-quality results in projects, from simple bends to complex shapes.

In this article, we will explore the essential techniques and best practices for using a hydraulic metal brake press. We will delve into the fundamental components of the machine, the importance of proper setup, and the various bending methods that can be employed. Whether you are a seasoned professional or a newcomer to metalworking, mastering the use of a hydraulic metal brake press will enhance your ability to create intricate designs while minimizing waste and optimizing productivity. Join us as we navigate through the steps to leverage this powerful tool for successful metal forming.

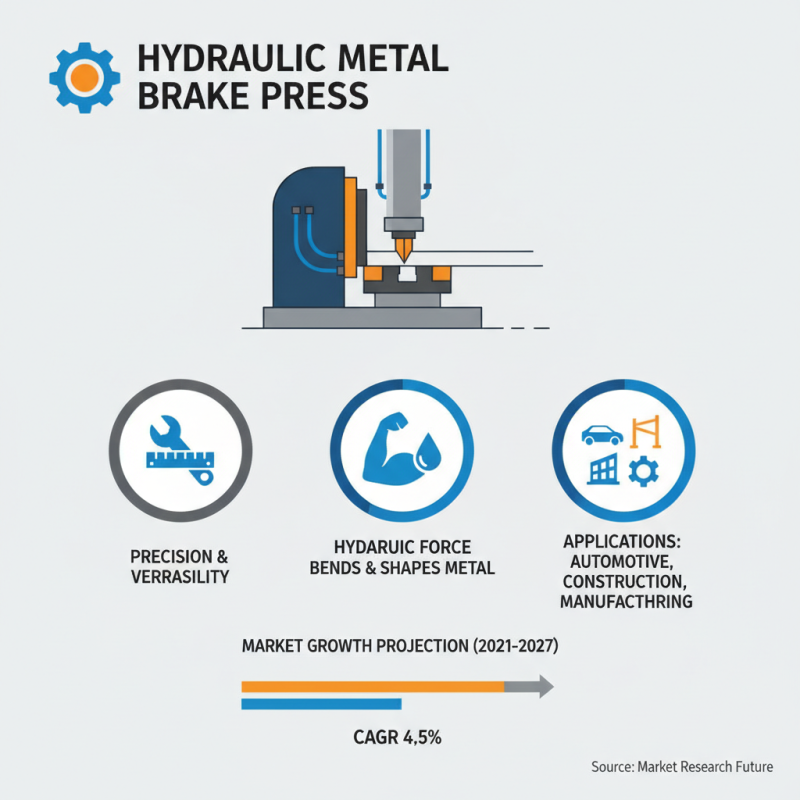

Overview of Hydraulic Metal Brake Press and Its Applications

A hydraulic metal brake press is an essential machine in the metalworking industry, particularly known for its precision and versatility in forming processes. This machinery operates by using hydraulic force to bend and shape sheet metal into specified angles and configurations. Its applications are widespread, ranging from the manufacturing of automotive components to the creation of intricate metal structures in construction. According to a report from Market Research Future, the hydraulic press market is projected to grow at a CAGR of 4.5% between 2021 and 2027, highlighting the increasing demand for such efficient metal forming technologies.

The range of applications for hydraulic metal brake presses is vast, catering to various industries including aerospace, electronics, and heavy machinery. For instance, in the aerospace sector, precision metal components are critical for ensuring safety and performance, and hydraulic presses provide the exacting standards needed. The ability to handle various materials—including aluminum, stainless steel, and carbon steel—adds to the versatility of hydraulic brake presses. Data from the Fabricators and Manufacturers Association reveals that over 75% of fabricators utilize such presses for tasks ranging from simple bends to complex formations, underscoring their indispensable role in modern manufacturing processes.

Understanding the Components and Mechanism of Hydraulic Brake Press

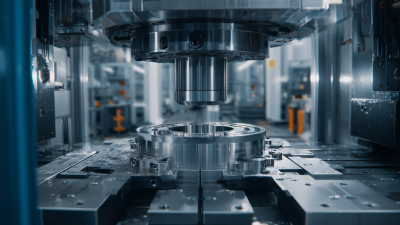

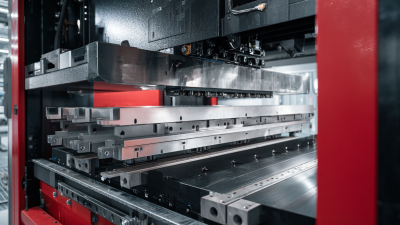

Hydraulic brake presses are essential tools in metal forming processes, characterized by their unique components and mechanisms that allow for precise and effective shaping of metals. At the heart of the hydraulic brake press is a powerful hydraulic system that utilizes pressurized fluid to generate force. This system consists of a hydraulic pump, cylinders, and valves, all working in unison to control the movement of the press's ram. When the operator activates the machine, the hydraulic pump sends fluid to the cylinders, causing the ram to lower and apply pressure on the metal workpiece. This mechanism ensures that the press can handle a variety of metal types and thicknesses, accommodating different forming needs.

Another critical component of the hydraulic brake press is the die set, which consists of the upper die and lower die. These dies determine the shape and angle of the bend produced in the metal. The precision of the bend is influenced not just by the configuration of the dies but also by the control of the ram's descent speed and pressure application. Operators can adjust these variables to achieve the desired bend radius and angle, ensuring accuracy in production. Additionally, the frame of the brake press must be robust enough to withstand the forces generated during bending, making the overall design pivotal for efficiency and safety in metal forming tasks. Understanding these components and their interactions is essential for anyone looking to utilize hydraulic brake presses effectively in their projects.

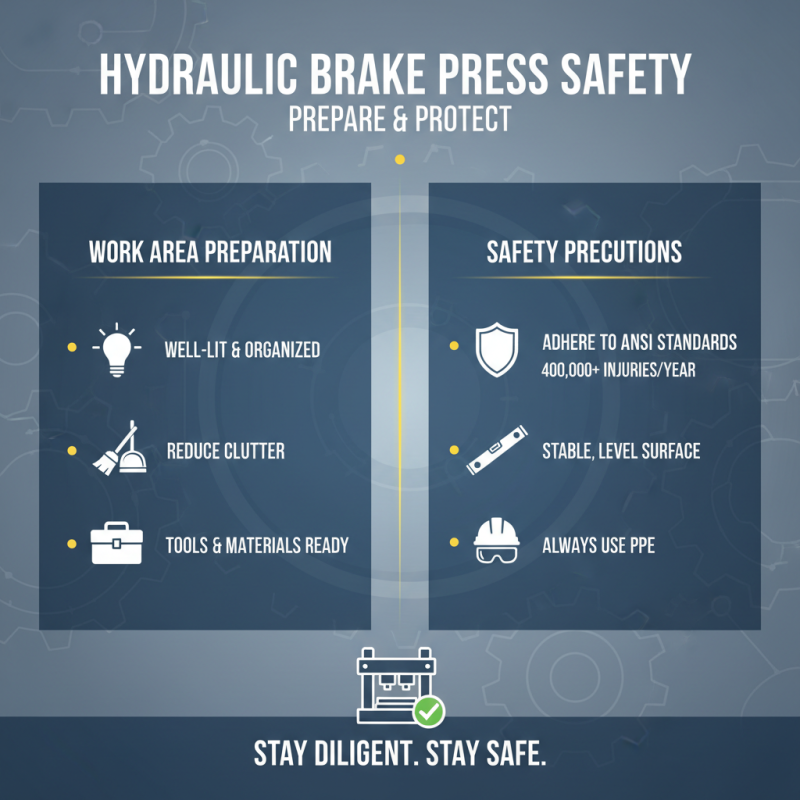

Preparing the Work Area and Safety Precautions for Metal Forming

When working with a hydraulic metal brake press, it is crucial to prepare the work area effectively and adhere to safety precautions. As per the American National Standards Institute (ANSI), safety in the metalworking industry is paramount, with over 400,000 reported injuries annually, showcasing the need for diligence when operating machinery. To create a safe work environment, ensure that the area is well-lit and organized, reducing clutter that can lead to accidents. All tools and materials should be within easy reach, and the machine should be placed on a stable, level surface to prevent tipping or movement during operation.

Personal protective equipment (PPE) is essential when working with machinery like a hydraulic metal brake press. According to the National Safety Council (NSC), protective gear reduces the risk of injury by approximately 70%. Operators should wear safety glasses to protect against flying debris, gloves to handle sharp edges, and steel-toed boots to safeguard against heavy materials. Furthermore, training in machine operation and safety protocols should be prioritized, as studies show that proper training can mitigate up to 60% of workplace accidents related to machinery. Regular maintenance checks on the brake press itself can prevent malfunctions and enhance both safety and efficiency during metal forming tasks.

Step-by-Step Guide to Setting Up and Operating a Brake Press

Setting up a hydraulic metal brake press involves several critical steps to ensure safety and efficiency during operation. Begin by thoroughly reviewing the manufacturer's manual to understand the specifications and capabilities of the machine. It's essential to select the right tooling for your specific metal forming needs; this includes choosing the proper die and punch to achieve the desired bend angle and radius. Next, ensure the press is located on a stable and level surface to prevent any instability while in use, and make sure that all safety guards are in place.

Once the brake press is set up, the actual operation requires careful attention to detail. Begin by adjusting the back gauge to the appropriate size for your workpiece. This ensures accurate cuts and bends. It’s also crucial to load the metal sheet securely in the machine, aligning it properly with the tooling. As you operate the press, maintain a steady and controlled motion to prevent sudden jarring of the machine. Regularly check for any signs of wear or malfunction, and always have safety gear on hand. By following these steps diligently, you can achieve effective metal forming with your hydraulic brake press.

How to Use a Hydraulic Metal Brake Press for Effective Metal Forming

| Step | Description | Tools Needed | Time Required |

|---|---|---|---|

| 1 | Set up the metal brake press securely on a stable surface. | Leveling Tool | 15 minutes |

| 2 | Install the appropriate die and punch for the metal thickness. | Wrench Set | 10 minutes |

| 3 | Adjust the back gauge to set the desired bend length. | Measuring Tape | 5 minutes |

| 4 | Position the metal sheet securely under the die. | Clamps | 5 minutes |

| 5 | Engage the hydraulic press to begin the forming process. | Hydraulic Control | 2 minutes |

| 6 | Release the pressure and inspect the bend accuracy. | Caliper | 3 minutes |

Techniques for Effective Metal Forming and Common Troubleshooting Tips

Hydraulic metal brake presses are essential tools in metal forming, providing precision and efficiency for various applications. To achieve effective metal forming, it's crucial to understand several techniques. One of the most effective methods is to utilize a progressive bending approach, which involves bending the material in stages rather than making a single, deep bend. According to recent industry reports, this technique can lead to a reduction in material stress and an improvement in the overall strength of the formed component, increasing the lifespan of the final product by up to 30%. Additionally, maintaining optimal pressure settings is vital. Too much pressure can lead to material cracking, while too little may result in insufficient forming.

Common troubleshooting tips can significantly enhance the effectiveness of your metal forming processes. For instance, if you notice uneven bends, it may indicate that the tooling is misaligned or worn out. Regular inspection and maintenance of tools can prevent these issues, ensuring consistent quality. Furthermore, varying the speed of the press during operation can help achieve more uniform results. Research shows that adjusting the bending speed can affect the microstructure of the metal, leading to better consistency in the final product. Monitoring the cooling times between bends is also key, as rapid cooling can induce unwanted stress and warping. Implementing these techniques and troubleshooting tips will not only improve the quality of the formed parts but also enhance productivity in the workshop.

Related Posts

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

Innovative Solutions for Efficient Metal Forming with the Best Small Press Brake

-

15 Reasons Why the Best Press Machine Can Transform Your Production Process

-

Mastering Sheet Metal Fabrication: Essential Tips for Choosing the Right Press Brake

-

The Future of Manufacturing Efficiency with Innovative Press Machine Technology Insights and Trends

-

Maximizing Precision and Efficiency in Fabrication with Advanced Sheet Metal Press Brake Technology