The Definitive Handbook to Sheet Metal Press Machines: Mastering Efficiency and Innovation

In the realm of manufacturing, the efficiency and effectiveness of production processes are paramount, and a sheet metal press machine stands at the forefront of this evolution. This definitive handbook aims to provide a comprehensive guide to understanding and utilizing sheet metal press machines, focusing on their innovative features and capabilities. As industries strive for higher productivity and precision, mastering the intricacies of these machines becomes essential for engineers and operators alike. This blog will delve into the key components, operational techniques, and maintenance practices that ensure optimal performance of sheet metal press machines. By equipping professionals with the necessary knowledge and skills, we hope to foster a deeper appreciation for these vital tools in the manufacturing sector, ultimately paving the way for increased efficiency and innovation in the production line.

Understanding the Basics: What is a Sheet Metal Press Machine?

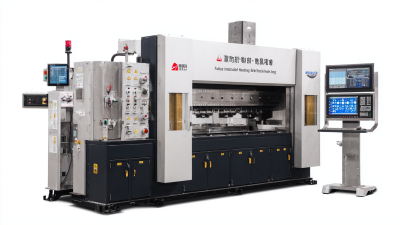

Sheet metal press machines are essential tools in the manufacturing sector, designed to cut, shape, and form metal sheets into various configurations. At their core, these machines use a combination of hydraulic or mechanical force to manipulate metals, enabling the production of complex parts with precision and consistency. The basic operation involves placing a metal sheet between a die and a punch; when the press is activated, the punch descends, forcing the sheet into the die to create the desired shape.

Understanding the fundamental components and operation of a sheet metal press machine is crucial for optimizing efficiency in production. These machines come in various types, including hydraulic, mechanical, and pneumatic presses, each offering unique advantages depending on the application. Mastering the technology behind these machines not only enhances productivity but also drives innovation within manufacturing processes, enabling the creation of more intricate and efficient designs. As industries increasingly rely on automation and advanced materials, having a solid grasp of sheet metal press machines will be vital for engineers and manufacturers alike.

The Definitive Handbook to Sheet Metal Press Machines: Mastering Efficiency and Innovation

| Dimension | Description | Typical Range |

|---|---|---|

| Working Pressure | Pressure applied to the sheet metal during the pressing process. | 30 - 250 tons |

| Stroke Length | Distance the punch travels downwards to press the sheet metal. | 50 - 250 mm |

| Table Size | Dimensions of the area where the workpiece is placed. | 1000 x 500 mm to 3000 x 1500 mm |

| Speed | Rate at which the machine operates during the pressing cycle. | 5 - 20 strokes per minute |

| Power Consumption | Amount of electrical power needed to operate the machine. | 5 - 30 kW |

| Control Type | System used for controlling the machine operations. | Manual, CNC, or PLC |

Key Features: Essential Components of Sheet Metal Press Machines

Sheet metal press machines are essential in the metal forming tools market, which is projected to expand significantly from $29.41 billion in 2025 to $51.67 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.4%. This robust growth underscores the importance of mastering the efficiency and innovation associated with these machines. Central to their operation are key components such as hydraulic systems, tooling, and automation technologies, which collectively enhance the precision and output of manufacturing processes.

The evolution of sheet metal press machines has been driven by advancements in materials science, particularly in the development of sustainable metals and alloys. Research highlights the need to address key scientific bottlenecks in metal synthesis from primary resources. Innovations in this area not only improve the performance and longevity of press machines but also contribute to more environmentally friendly manufacturing practices. The integration of smart technology and advanced materials will be pivotal in meeting the rising demands of the industry while fostering sustainability.

Innovative Technologies: Enhancing Efficiency in Sheet Metal Pressing

In the ever-evolving landscape of metal forming, innovative technologies are key to enhancing efficiency in sheet metal pressing. As industries recognize the benefits of advanced machinery, the global metal forming tools market is projected to grow significantly, reaching $51.67 billion by 2032. This growth highlights the increasing demand for high-performance equipment designed to optimize production processes and reduce operational costs.

The Metal Forming Expo serves as a premier platform for showcasing the latest advancements in sheet metal working technologies. By bringing together industry leaders and innovators, the event highlights the importance of embracing cutting-edge solutions that drive performance and sustainability. From automating processes with AI-driven machinery to utilizing eco-friendly materials, the expo emphasizes that innovation is not just beneficial, but essential for staying competitive in the market. As we look ahead, mastering efficiency through these technologies will be crucial for manufacturers aiming to thrive in a rapidly changing environment.

Best Practices: Optimizing Operations for Maximum Productivity

Optimizing operations in the realm of sheet metal press machines is crucial for maximizing productivity and ensuring efficient workflows. One of the foremost best practices is regular maintenance and calibration of the machines. A well-maintained press can significantly reduce downtime and enhance output quality, leading to both time and cost savings. Implementing a structured maintenance schedule allows manufacturers to anticipate possible issues before they escalate, ensuring that the machines operate at peak performance.

Moreover, proper training for operators plays a vital role in optimizing operations. Skilled operators are more proficient in handling machinery, understanding its intricacies, and troubleshooting minor issues that could disrupt production. Continuous education and training programs not only boost the confidence of operators but also foster an environment of innovation where employees are encouraged to propose improvements in processes and techniques. By focusing on both maintenance and training, companies can establish a robust operational framework that promotes productivity and competitiveness in the market.

Future Trends: The Evolution of Sheet Metal Press Machines in Industry

The evolution of sheet metal press machines is driven by a combination of technological advancements and the demand for increased efficiency in manufacturing processes. According to a report by MarketsandMarkets, the sheet metal fabrication market is projected to reach $251 billion by 2026, with a compound annual growth rate (CAGR) of 4.3%. This growth is largely influenced by the introduction of smart manufacturing technologies, such as IoT integration and AI-based predictive maintenance, which enhance the operational capabilities of sheet metal press machines.

As industries strive for sustainability and cost-effectiveness, the shift towards automation and advanced robotics in sheet metal processing becomes evident. A study from Technavio indicates that the global market for automated sheet metal fabrication is expected to grow at a CAGR of around 7% over the next five years. This integration not only improves production speeds but also minimizes waste, aligning with the growing emphasis on environmentally friendly manufacturing practices. As such, the future of sheet metal press machines lies in their ability to adapt to these technological shifts, ensuring manufacturers can remain competitive while meeting evolving market demands.

Related Posts

-

Understanding the Benefits of the Best Industrial Press Machine in Manufacturing

-

The Ultimate Guide to Choosing the Best CNC Press Brake Machine for Your Manufacturing Needs

-

Innovative Approaches to Selecting the Best Brake Machine for Global Buyers

-

Craftsmanship Redefined Chinese Manufacturing Delivering the Best Press Brake Solutions Worldwide

-

Future Innovations in Small Hydraulic Press Brake Technology for 2025 Global Buyers

-

Unlocking Precision: The Best Press Brake Machines from China’s Premier Manufacturing Factory