Global Reach with China's Top Hydraulic Metal Shear Machines: Precision Engineering Redefined

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher, especially in the metal fabrication sector. The hydraulic metal shear machine stands out as a pivotal tool, combining advanced engineering with reliability to meet the rigorous standards of modern industries. According to a recent report by Global Industry Analysts, the global metal fabrication machinery market is projected to reach USD 129 billion by 2026, growing significantly due to the rising demand for precision-engineered products across various sectors. This growth is largely fueled by the adoption of advanced machinery, particularly hydraulic shears, which offer unparalleled cutting accuracy and volume. As China continues to lead the way in manufacturing innovation, its top hydraulic metal shear machines not only enhance production capabilities but also redefine precision engineering, setting a benchmark for quality and efficiency on a global scale.

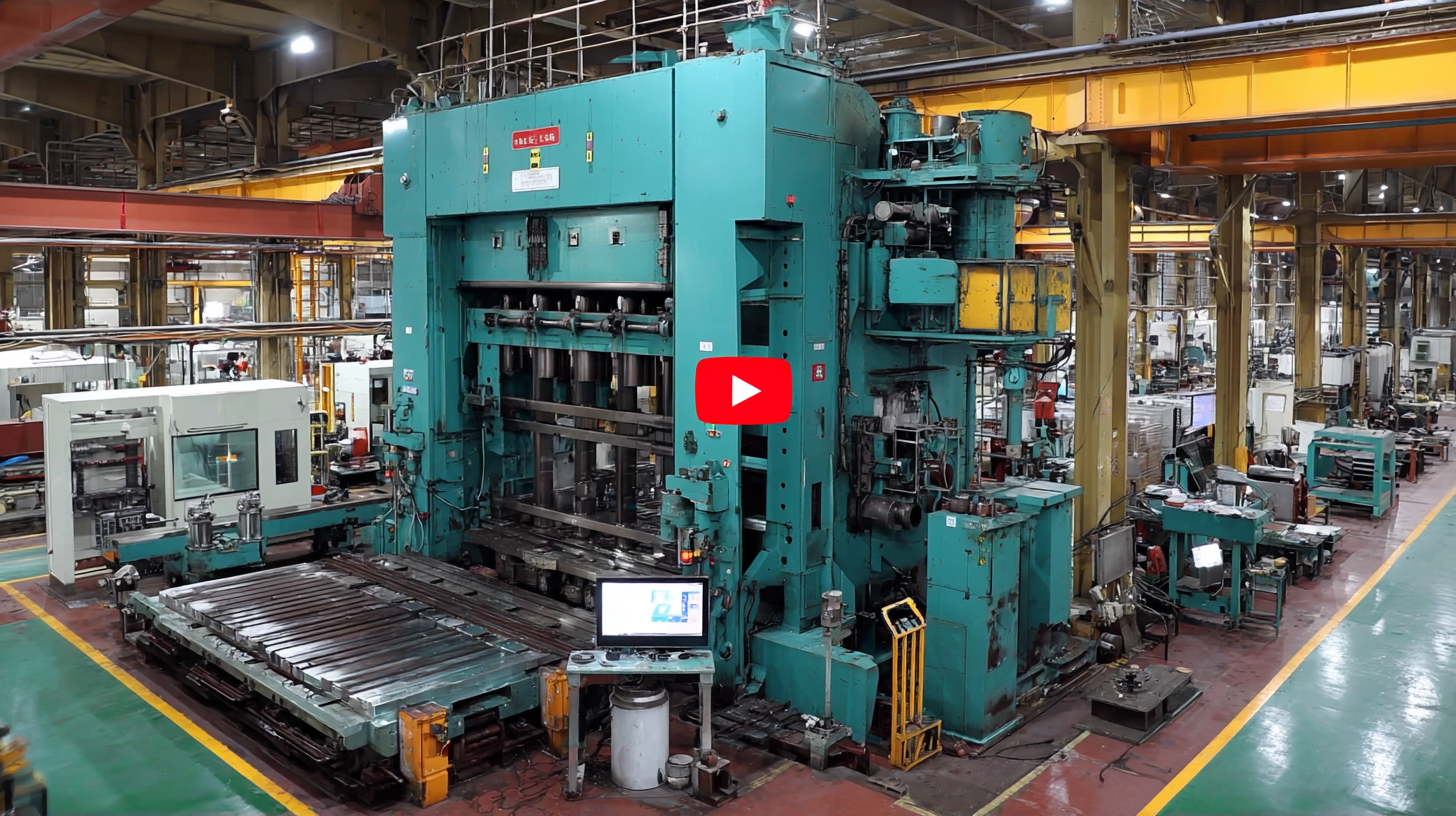

The Rise of China's Hydraulic Metal Shear Machines in Global Markets

The rise of China's hydraulic metal shear machines has marked a significant shift in the global machinery market. With increasing precision engineering capabilities, these machines are not only enhancing productivity but are also redefining industry standards worldwide. As manufacturers seek to optimize their metal fabrication processes, the demand for advanced hydraulic shear technologies has surged, leading China to become a prominent player on the international stage.

According to a recent market research study, the global hydraulic press machine market is poised for substantial growth, expected to increase by USD 4.37 billion from 2024 to 2028. This surge is primarily driven by the automotive sector's need for fabricated metal components, where precision and efficiency are critical. As China continues to innovate and improve the quality of its machinery, its hydraulic metal shear machines are set to capture a larger share of these emerging markets, showcasing the nation's significant role in the evolution of industrial manufacturing on a global scale.

Precision Engineering: The Key Features of China's Hydraulic Shears

China has emerged as a leader in the global metal forming tools market, particularly with its hydraulic metal shear machines, which are redefining precision engineering. The global market for these tools was valued at $32.29 billion in 2018 and is projected to reach $66.91 billion by 2032, growing at a CAGR of 4.9%. This demonstrates the increasing demand for high-quality, efficient cutting tools that enhance productivity in metal processing industries.

Hydraulic shear machines from China are engineered with several key features that stand out in the competitive landscape. They offer enhanced cutting accuracy and speed, making them essential for industries that require high precision. Advanced blade designs, automated features, and robust construction contribute to their reliability and longevity. These innovations not only improve operational efficiency but also reduce waste and operational costs.

**Tips for Selecting Hydraulic Shears:**

1. Evaluate the machine’s cutting capacity to ensure it meets your specific material thickness requirements.

2. Consider automation features that can streamline operations and improve safety.

3. Look for machines with adjustable shear angles to provide versatility for different applications.

Global Reach: Key Features of China's Hydraulic Shears

This chart illustrates the key features of China's hydraulic metal shear machines, highlighting their cutting capacity, blade width, stroke length, weight, and power. These parameters redefine precision engineering in the metal processing industry.

Statistics Show China's Hydraulic Shears Lead in Efficiency and Durability

The hydraulic metal shear machines produced in China have emerged as frontrunners in the global manufacturing landscape, particularly in terms of efficiency and durability. Statistics indicate that these machines significantly outperform their competitors in various key performance metrics. For instance, advanced hydraulics technology and robust construction materials allow these shears to endure prolonged use without compromising cutting precision or operational efficiency. As production demands escalate, the resilience of China’s hydraulic shears becomes even more critical, ensuring they remain effective under continuous pressure.

Moreover, the efficiency of these machines is manifest in their ability to reduce processing times and minimize energy consumption. Manufacturers utilizing Chinese hydraulic shears report substantial gains in productivity, translating to lower operating costs and improved output. This combination of durability and efficiency not only positions China as a leader in the hydraulic shear market but also sets a new standard for precision engineering. With ongoing innovations and an unwavering commitment to quality, China's hydraulic shears are redefining what businesses can expect from metal cutting equipment.

Environmental Impact: How China's Shear Machines Promote Sustainable Practices

China's hydraulic metal shear machines have not only revolutionized precision engineering but also play a crucial role in sustainable industrial practices. These advanced machines are designed with efficiency in mind, significantly reducing waste during the cutting process. By utilizing high-quality materials and innovative technology, they enhance the overall performance while minimizing energy consumption. This commitment to excellence leads to a decrease in greenhouse gas emissions, supporting a shift towards environmentally friendly manufacturing.

Moreover, China's shear machines are often equipped with features that promote recycling and resource conservation. Many models integrate advanced sensor technology and automation, ensuring that materials are cut with maximum efficiency, thus reducing scrap metal. Additionally, these machines help industries adhere to stricter environmental regulations by ensuring that production waste is kept to a minimum. As global demand for sustainable practices increases, the impact of China's hydraulic metal shear machines demonstrates how advancing technology can align industrial growth with ecological responsibility, shaping a greener future for the manufacturing sector.

Global Reach with China's Top Hydraulic Metal Shear Machines: Precision Engineering Redefined - Environmental Impact: How China's Shear Machines Promote Sustainable Practices

| Model | Shearing Capacity (mm) | Cutting Speed (m/min) | Energy Efficiency (%) | Recyclable Materials (%) | Noise Level (dB) |

|---|---|---|---|---|---|

| Model A | 6 | 12 | 85 | 90 | 75 |

| Model B | 8 | 10 | 82 | 85 | 77 |

| Model C | 10 | 15 | 90 | 92 | 70 |

Case Studies: Success Stories from Industries Utilizing Chinese Shear Technology

In the realm of modern manufacturing, China's hydraulic metal shear machines have gained remarkable recognition for their precision engineering and efficiency. Industries around the globe are implementing these advanced shear technologies, leading to enhanced production capabilities and streamlined operations. Case studies from various sectors highlight successful applications of this technology, showcasing its adaptability to different manufacturing environments and its role in elevating operational standards.

Tips: When integrating hydraulic shear machines into your production line, consider factors such as the specific material types and thicknesses you will be working with. This understanding will help you select the right machine configuration that maximizes performance. Furthermore, regular maintenance and operator training are crucial to maintaining precision and prolonging the life of your equipment.

Several industries report significant improvements in operational efficiency and product quality after adopting these cutting-edge machines. The automotive sector, for instance, has utilized Chinese shear technology to achieve cleaner cuts and faster processing times, reducing waste and overall costs. As more companies embrace these innovations, they continue to redefine the standards of precision engineering on a global scale.