The Future of Manufacturing Efficiency with Innovative Press Machine Technology Insights and Trends

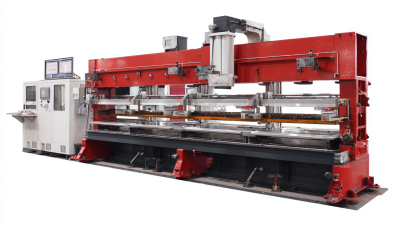

In the rapidly evolving landscape of manufacturing, the integration of innovative press machine technology is set to revolutionize efficiency and productivity across various sectors. According to a recent report by MarketsandMarkets, the global press machine market is expected to reach $34.3 billion by 2025, driven by increasing automation and demand for high precision in manufacturing processes.

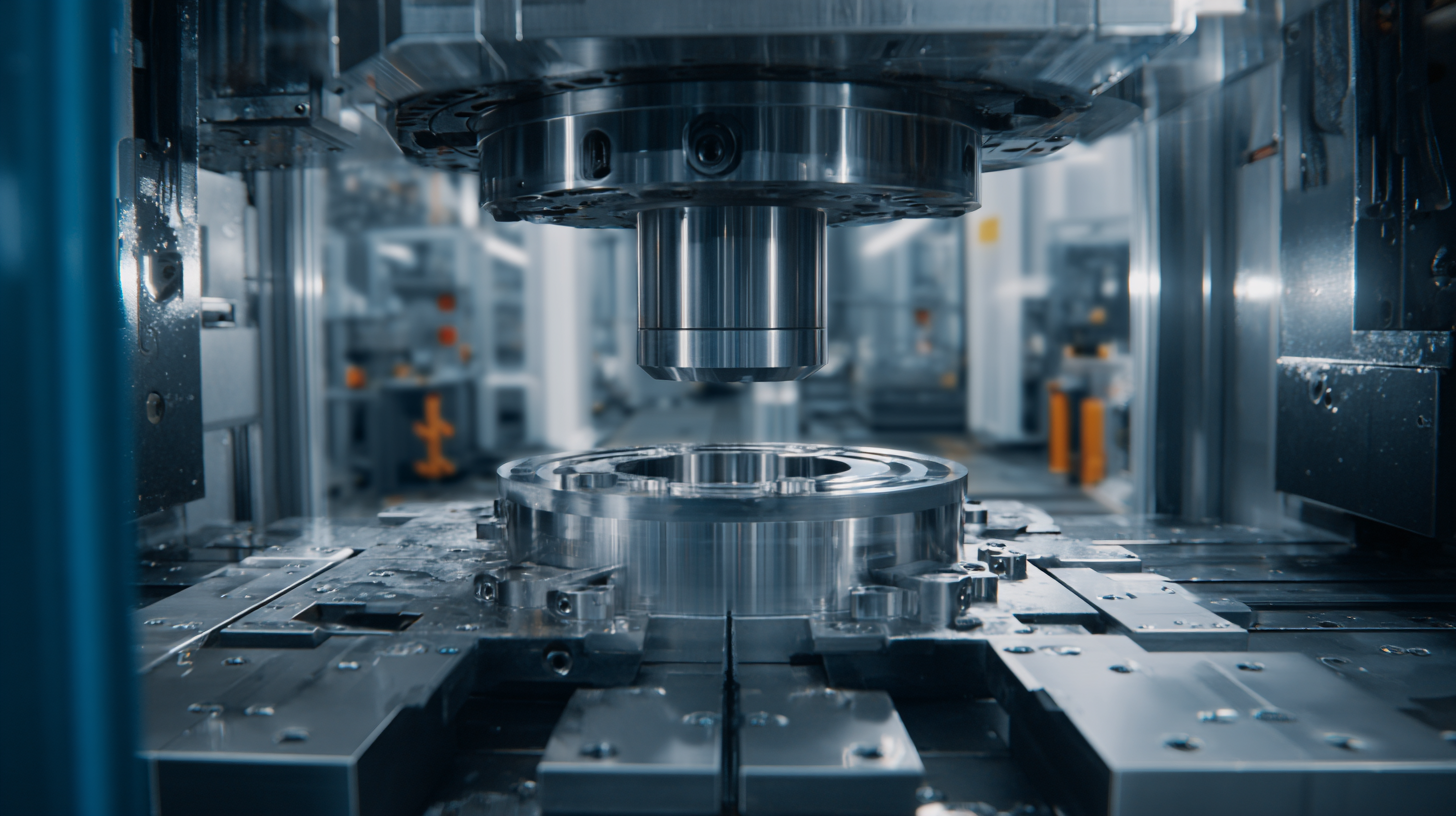

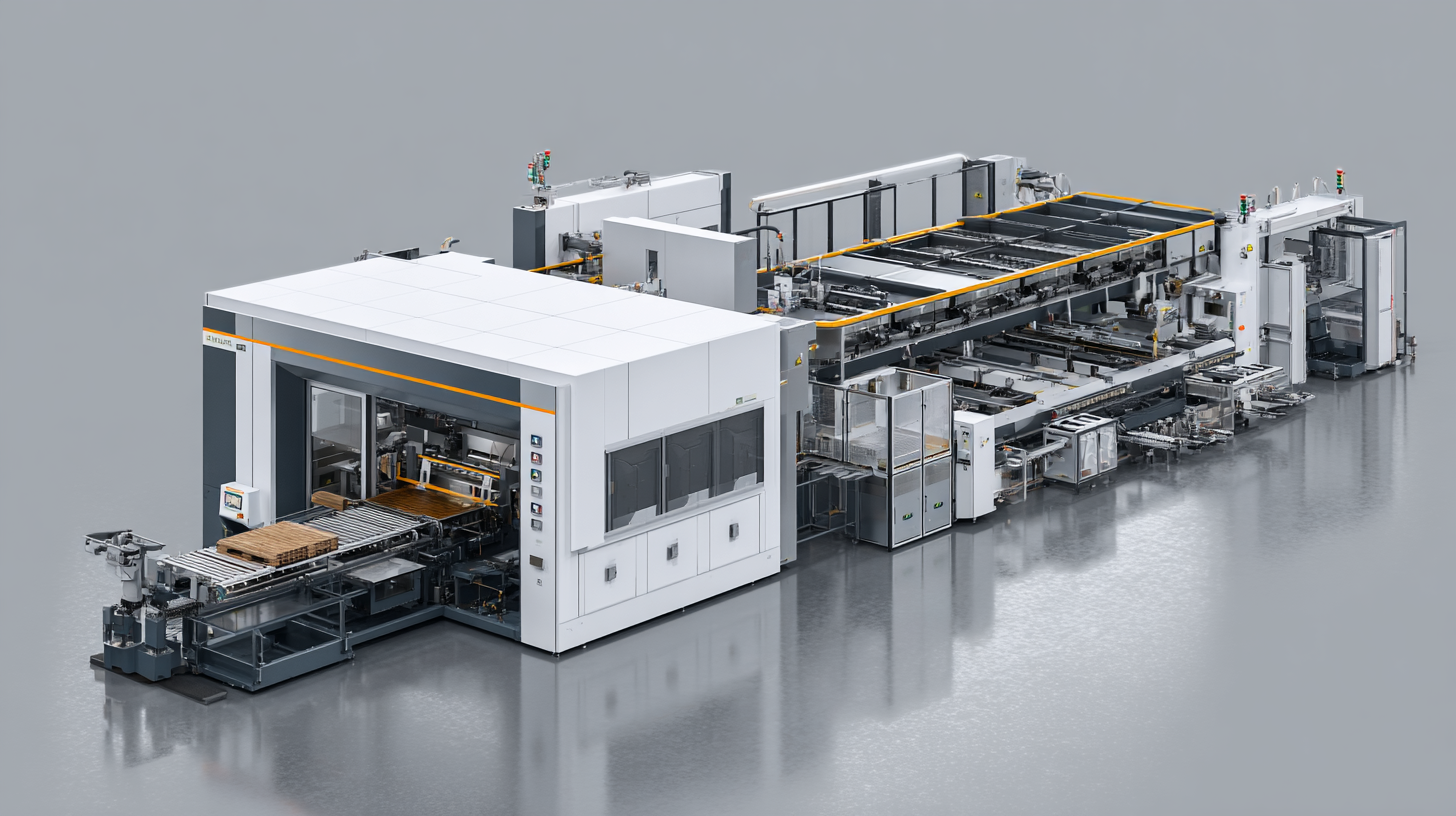

The advent of advanced features such as servo-driven press machines and smart manufacturing solutions is enhancing operational efficiencies, reducing cycle times and minimizing material waste. As industries seek to optimize their production capabilities, understanding the latest trends and insights in press machine technology becomes crucial for maintaining a competitive edge.

This article will explore pivotal strategies and innovations shaping the future of manufacturing efficiency through state-of-the-art press machine applications.

Emerging Trends in Press Machine Technology: Harnessing Digital Innovations for Efficiency

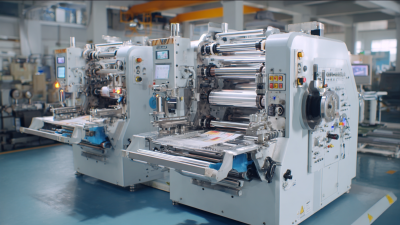

The manufacturing sector is experiencing a significant transformation, driven largely by advancements in press machine technology and the integration of digital innovations. Emerging trends emphasize the importance of artificial intelligence (AI), which is reshaping operational efficiencies through enhanced predictive maintenance and autonomous processes. By harnessing AI capabilities, manufacturers can optimize their workflows, reduce downtime, and improve overall production quality. This integration not only streamlines processes but also fosters an adaptable manufacturing environment capable of responding to market dynamics swiftly.

Moreover, the adoption of digital dynamic capabilities allows organizations to enhance their sustainability performance while driving operational efficiencies. The synergy of green technology and innovative practices enables companies to minimize waste and energy consumption, aligning with modern sustainability goals. Smart technology solutions are increasingly being integrated into press machines, leading to a more intelligent manufacturing ecosystem that maximizes productivity without compromising environmental responsibility. As these trends continue to evolve, the future of manufacturing looks increasingly promising, emphasizing efficiency through innovation.

The Role of IoT in Enhancing the Performance of Manufacturing Press Machines

The integration of the Internet of Things (IoT) into manufacturing processes has revolutionized the performance of press machines, leading to unprecedented levels of efficiency and productivity. IoT technology enables real-time data collection and analysis, allowing manufacturers to monitor machine operations and identify potential issues before they escalate. Sensors embedded in press machines collect critical metrics such as temperature, pressure, and material flow, which are then transmitted to centralized systems for assessment. This immediate feedback loop ensures that adjustments can be made quickly, reducing downtime and optimizing the production cycle.

Moreover, IoT enhances predictive maintenance capabilities, which is essential for the longevity and reliability of manufacturing equipment. By leveraging algorithms that analyze historical performance data, manufacturers can predict when parts are likely to fail and schedule maintenance accordingly. This proactive approach minimizes unplanned outages and allows for more strategic resource allocation. As manufacturers continue to adopt IoT-integrated press machines, we expect to see significant improvements in production quality and overall operational efficiency, paving the way for smarter, more agile manufacturing environments.

Data-Driven Insights: How AI is Transforming Press Machine Operations

The manufacturing industry is undergoing a remarkable transformation, driven by the integration of artificial intelligence (AI) into press machine operations. This shift is not only enhancing efficiency but also optimizing production processes. AI-powered analytics provide real-time insights, enabling manufacturers to make data-driven decisions that can significantly reduce downtime and improve overall productivity.

To leverage AI effectively, manufacturers should consider implementing predictive maintenance strategies. By analyzing historical performance data and machine conditions, AI can forecast potential failures before they occur. This proactive approach minimizes disruptions and ensures seamless operations.

Furthermore, investing in smart press machines equipped with IoT connectivity can enhance data collection and sharing. These machines can communicate operational metrics in real-time, allowing for quick adjustments and better resource allocation. Manufacturers looking to improve their operational efficiency should prioritize these technologies to stay competitive in the evolving landscape. Embracing this data-driven approach is crucial for shaping the future of manufacturing efficiency.

Sustainability in Manufacturing: The Impact of Eco-Friendly Press Technologies

The manufacturing industry is undergoing a significant transformation as the demand for sustainability grows. Eco-friendly press technologies are at the forefront of this change, enabling manufacturers to reduce their environmental footprint. These innovative machines utilize advanced materials and processes that consume less energy and generate lower emissions compared to traditional methods. By implementing sustainable practices, companies not only comply with regulatory standards but also attract environmentally conscious consumers, enhancing their market competitiveness.

Moreover, the integration of smart technology into press machines amplifies their eco-friendly benefits. With features such as real-time monitoring and automation, manufacturers can optimize their production processes, minimize waste, and conserve resources. This aligns with the global trend towards sustainable manufacturing, where efficiency and eco-friendliness are not mutually exclusive but rather complementary.

As this technology continues to evolve, it paves the way for a greener future in manufacturing, urging industries to embrace these innovations for both economic and environmental gains.

Measuring Efficiency: Key Performance Indicators for Modern Press Machine Systems

In the realm of modern manufacturing, measuring efficiency is paramount to maintaining competitive advantage. Key Performance Indicators (KPIs) play a crucial role in assessing the effectiveness of press machine systems. By focusing on metrics such as production rate, downtime, and energy consumption, manufacturers can gain insights into the operational performance of their machinery.

High production rates signal optimal efficiency, while analyzing downtime can help identify bottlenecks in the workflow that need to be addressed.

Energy consumption is another vital KPI that reflects both operational efficiency and sustainability efforts. With increasing pressure to reduce carbon footprints, manufacturers are investing in press machines equipped with advanced technologies that minimize energy usage while maximizing output.

Furthermore, real-time monitoring systems allow for continuous assessment of these KPIs, enabling quick adjustments to improve overall efficiency. As innovative press machine technology evolves, these metrics will become even more sophisticated, empowering manufacturers to streamline operations and enhance productivity in a rapidly changing industrial landscape.

Related Posts

-

15 Reasons Why the Best Press Machine Can Transform Your Production Process

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

Solutions for Optimizing Efficiency with the Best Manual Press Machine

-

Exploring the Unique Features and Applications of Various Best Press Machine Types

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

Comprehensive Manual Press Machine Guide: Everything You Need to Know for Optimal Use