The Future of Manufacturing Efficiency with CNC Hydraulic Press Brake Technology Insights and Trends

As manufacturers increasingly seek to optimize production processes, the integration of advanced technologies becomes paramount. One such advancement is the CNC hydraulic press brake, which has revolutionized bending operations across various industries. According to a report by Technavio, the global CNC machine tools market is expected to grow by over $5 billion from 2021 to 2025, with the demand for precision-engineered equipment like CNC hydraulic press brakes driving this growth. This technology not only enhances manufacturing efficiency through automation and accuracy but also reduces material wastage and labor costs. Industry experts predict that incorporating CNC hydraulic press brakes can lead to a 30% increase in productivity and a significant reduction in lead times. As we look to the future, understanding the insights and trends surrounding CNC hydraulic press brake technology is essential for manufacturers aiming to stay competitive in an ever-evolving market.

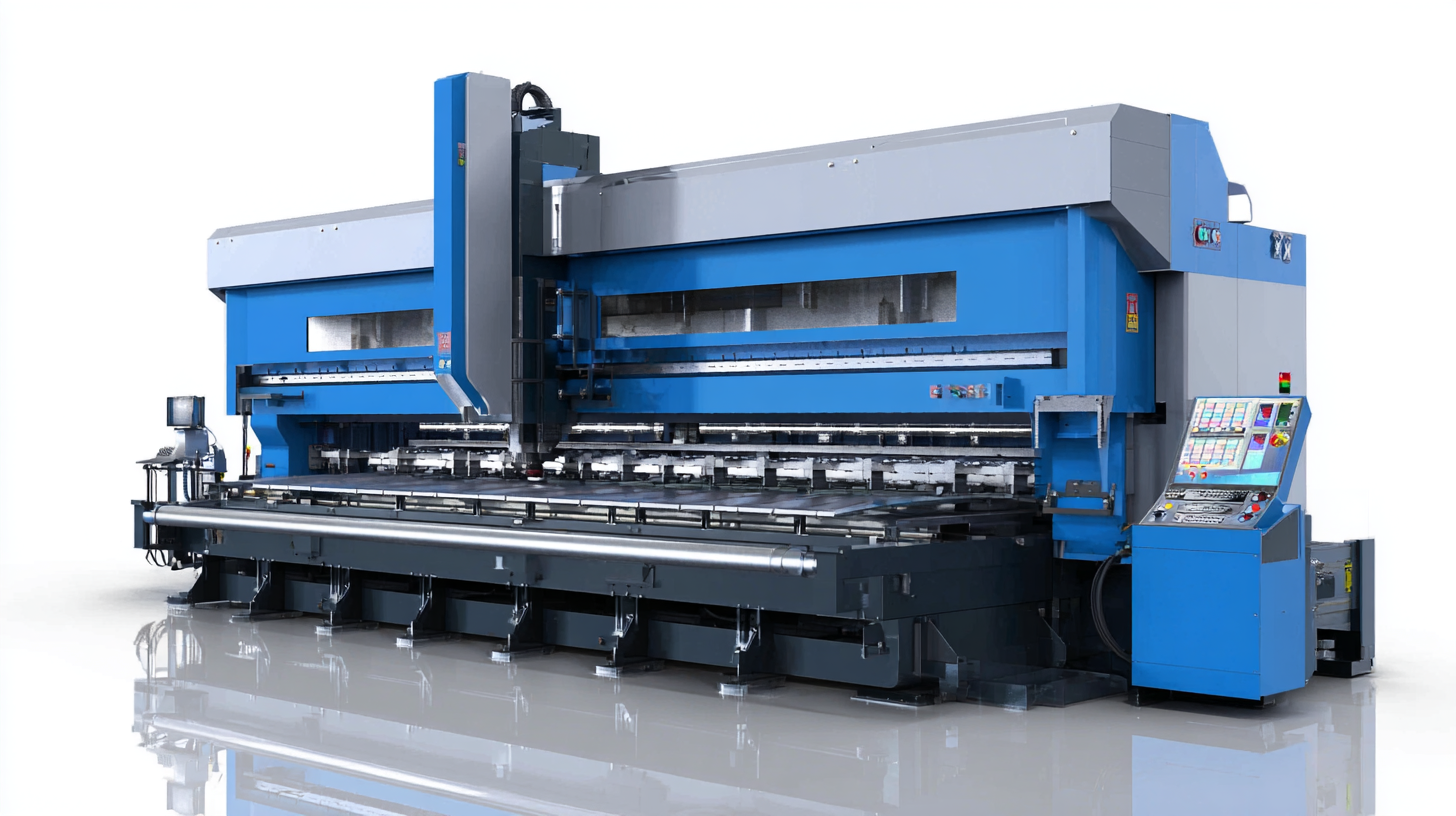

The Evolution of CNC Hydraulic Press Brake Technology in Modern Manufacturing

The evolution of CNC hydraulic press brake technology has significantly reshaped the landscape of modern manufacturing. In the past, metal bending processes often relied on manual methods, which were labor-intensive and prone to errors. However, the advent of CNC (Computer Numerical Control) technology has introduced precision and consistency, allowing manufacturers to achieve intricate designs with minimal waste. This shift not only enhances the speed of production but also elevates the quality of the final products, meeting the demands of an increasingly competitive market.

Moreover, the integration of advanced hydraulic systems has further improved the capabilities of CNC press brakes. Modern machines are equipped with sophisticated control systems that enable real-time monitoring and adjustments during the bending process. This has resulted in higher efficiency rates, reduced downtime, and a significant decrease in production costs. As manufacturers continue to embrace these innovations, the focus will be on sustainable practices and energy efficiency, ensuring that CNC hydraulic press brake technology plays a crucial role in shaping the future of the manufacturing sector.

Key Performance Metrics: Analyzing Efficiency Gains from CNC Hydraulic Press Brakes

The advent of CNC hydraulic press brakes has revolutionized the manufacturing landscape by significantly enhancing efficiency and precision in metal fabrication processes. Key performance metrics reveal the extent of these efficiency gains, particularly in terms of cycle time reduction and improved accuracy. With CNC technology, manufacturers can automate complex bending operations, thereby minimizing human error and ensuring consistent results across multiple production runs. This level of reliability is critical in maintaining quality standards while increasing output.

The advent of CNC hydraulic press brakes has revolutionized the manufacturing landscape by significantly enhancing efficiency and precision in metal fabrication processes. Key performance metrics reveal the extent of these efficiency gains, particularly in terms of cycle time reduction and improved accuracy. With CNC technology, manufacturers can automate complex bending operations, thereby minimizing human error and ensuring consistent results across multiple production runs. This level of reliability is critical in maintaining quality standards while increasing output.

Moreover, the integration of advanced software and real-time data analytics in CNC hydraulic press brakes allows manufacturers to optimize their workflows further. By monitoring key indicators such as throughput, energy consumption, and maintenance schedules, businesses can make informed decisions that lead to continuous improvement. The ability to swiftly adapt to changing production demands without compromising on quality provides a distinct competitive advantage in today's fast-paced market. As manufacturers continue to embrace CNC hydraulic press brake technology, the focus on these performance metrics will be crucial for driving ongoing efficiency gains and operational excellence.

Integrating IoT and AI: Transforming CNC Hydraulic Press Brake Operations

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into CNC hydraulic press brake operations marks a significant transformation in the manufacturing landscape. These advanced technologies enable real-time monitoring and data analysis, enhancing operational efficiency and precision. By equipping hydraulic press brakes with IoT sensors, manufacturers can gather crucial data on machine performance, material usage, and maintenance needs. This data-driven approach allows for predictive maintenance, reducing downtime and ensuring seamless production flows.

Moreover, AI algorithms can optimize the programming and operational parameters of CNC hydraulic press brakes, creating highly adaptive systems that can learn from past performance. This adaptability translates into improved accuracy in bending processes, reducing the likelihood of errors and material wastage. As companies embrace these innovations, the result is a more streamlined manufacturing process, fostering higher productivity levels and improved product quality. The synergy between IoT and AI not only drives efficiency but also empowers manufacturers to respond swiftly to market demands, ultimately revolutionizing the future of manufacturing.

The Future of Manufacturing Efficiency with CNC Hydraulic Press Brake Technology Insights and Trends - Integrating IoT and AI: Transforming CNC Hydraulic Press Brake Operations

| Dimension | Value |

|---|---|

| CNC Press Brake Efficiency Improvement (%) | 25% |

| Reduction in Setup Time (%) | 30% |

| Increase in Production Rate (%) | 20% |

| Cost Reduction in Operations (%) | 15% |

| IoT Adoption Rate (%) | 70% |

| AI Integration Rate (%) | 50% |

| Predictive Maintenance Impact (%) | 35% |

| Overall Equipment Effectiveness Improvement (%) | 18% |

Sustainability Trends: The Role of CNC Hydraulic Press Brakes in Eco-Friendly Manufacturing

The increasing emphasis on sustainability in manufacturing has made CNC hydraulic press brakes pivotal in promoting eco-friendly practices. These advanced machines not only enhance manufacturing efficiency but also contribute significantly to reducing environmental impact. By precisely bending metal sheets with minimal waste, CNC hydraulic press brakes allow manufacturers to optimize material use and increase recycling rates. This capability aligns with the global trend towards sustainable production, where reducing carbon footprints and resource consumption are paramount.

Projected growth in the metal sheet bending machine market from USD 1.04 billion in 2025 to USD 1.37 billion by 2035 signals a growing recognition of these technologies' benefits. As manufacturers seek to adopt greener practices, CNC hydraulic press brakes offer an effective solution for achieving sustainability goals. Their role in facilitating precise manufacturing processes helps users meet the increasing demand for eco-friendly products, ultimately helping the industry transition towards more responsible and sustainable operations. The comprehensive improvements in efficiency and sustainability offered by CNC technology make it an essential component of modern manufacturing strategies.

Future Innovations: Predictive Maintenance and Smart Features in CNC Technology

The advancements in CNC technology are paving the way for a significant transformation in manufacturing efficiency, primarily through the incorporation of predictive maintenance and smart features. As industries increasingly look to optimize operations, predictive maintenance is becoming a cornerstone of CNC machinery management. By leveraging real-time data and artificial intelligence, manufacturers can anticipate equipment failures before they occur, reducing downtime and ensuring continuous production flow. This shift from traditional time-based maintenance to a more dynamic, data-driven approach enhances overall productivity.

In addition to predictive maintenance, the integration of smart features into CNC technologies is driving the evolution of manufacturing processes. These features often include automated adjustments, remote monitoring, and advanced analytics that allow operators to make informed decisions quickly. As a result, manufacturers can not only improve the precision and quality of their outputs but also respond swiftly to changing market demands. The global CNC machine market is expected to grow significantly in the coming years, reflecting the ongoing trend toward automation and smarter manufacturing solutions that promise higher efficiency and lower operational costs.

The Future of Manufacturing Efficiency with CNC Hydraulic Press Brake Technology

This chart illustrates the projected efficiency improvements in CNC hydraulic press brake technology over the next five years, focusing on predictive maintenance and smart features. The data reflects estimated efficiency gains in percentage terms, based on industry trends and technological advancements.

Related Posts

-

Maximize Productivity: How Our After-Sales Services and Low Maintenance Costs Elevate Your CNC Hydraulic Press Brake Experience

-

Unlock Precision and Reliability: Partner with China's Finest for Hydraulic Press Brake Solutions

-

Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs

-

Why Small Press Brakes Are Essential for Precision Metal Bending in Modern Manufacturing

-

Discover the Excellence of China's Leading Factory for the Best Small Press Brake Solutions Worldwide

-

Craftsmanship Redefined Chinese Manufacturing Delivering the Best Press Brake Solutions Worldwide