Future Innovations in Small Hydraulic Press Brake Technology for 2025 Global Buyers

As we look ahead to 2025, the manufacturing industry is poised for a technological transformation, particularly in the realm of small hydraulic press brakes. According to a recent report by MarketsandMarkets, the global press brake market is projected to reach USD 3.5 billion by 2025, with a significant segment driven by the growing demand for precision and efficiency in metal forming processes. Small hydraulic press brakes, known for their versatility and capability to handle various materials, are gaining popularity among manufacturers aiming to optimize their production lines. With advancements in automation, software integration, and energy efficiency, the innovations in small hydraulic press brake technology promise to enhance operational efficiency while reducing environmental impact. As global buyers prepare to navigate these changes, understanding the future trends and technologies in this niche will be crucial for maintaining competitive advantage.

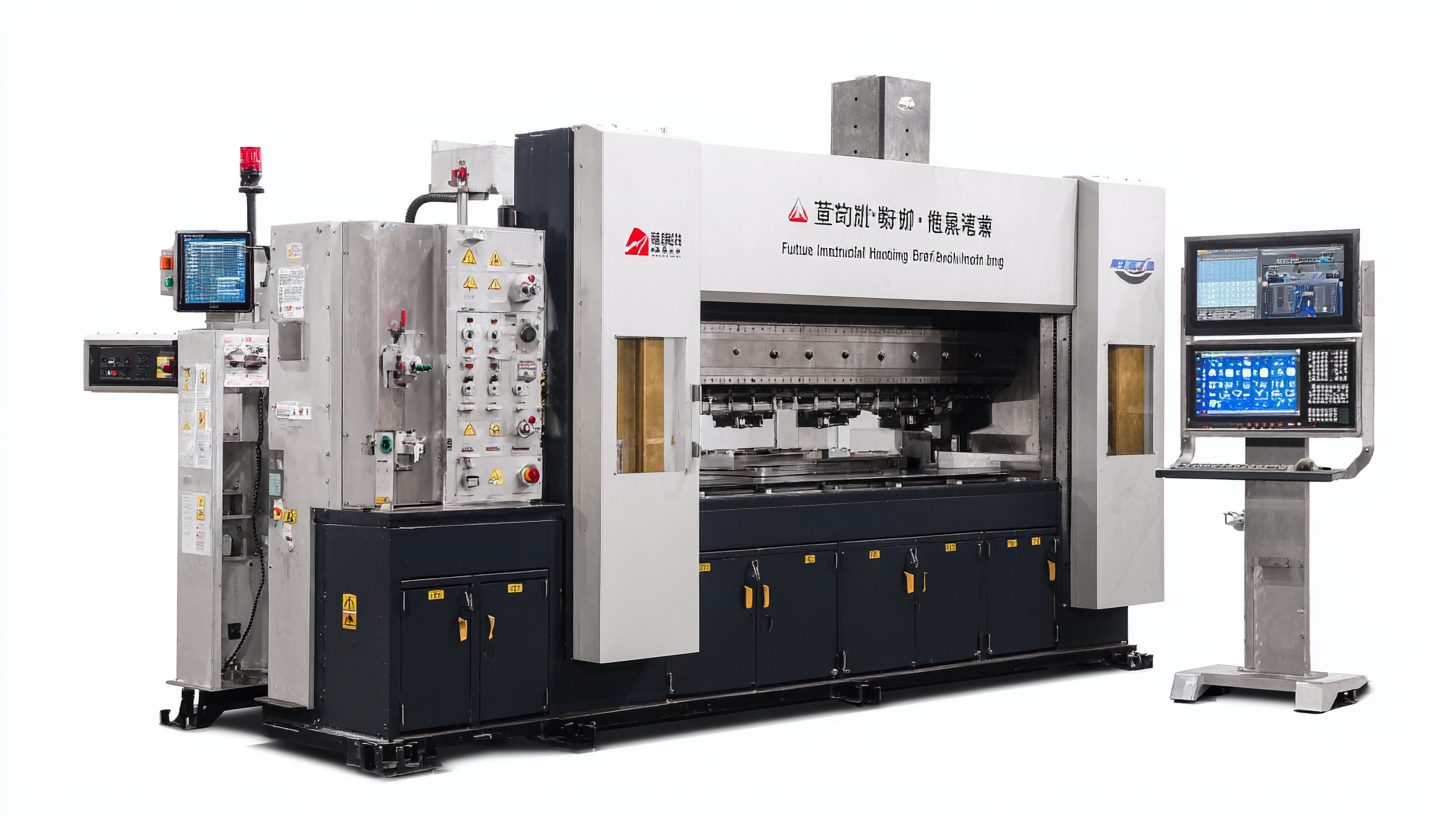

Emerging Trends in Hydraulic Press Brake Design for Enhanced Efficiency

The landscape of hydraulic press brake technology is poised for significant advancements by 2025, particularly in the context of the automotive and metal fabrication industries. With the global automotive brake systems market projected to grow from $45.57 billion in 2024 to $64.01 billion by 2032, a notable CAGR of 4.3%, there is a strong push for innovations that enhance efficiency and performance in braking systems. As manufacturers strive to meet increasing demands, emerging trends in hydraulic press brake design focus on optimizing energy consumption and operational efficacy.

At the forefront of these innovations is the integration of advanced hydraulics. The bauma 2025 exhibition is expected to showcase the latest technologies that not only comply with but exceed industry standards for efficiency and performance. In parallel, the global metal sheet bending machine market is anticipated to rise from $1.04 billion in 2025 to $1.37 billion by 2035, highlighting the growing need for more sophisticated and efficient machinery. As industries adapt to these trends, the emphasis on energy-efficient and low-pollutant hydraulic systems is paramount, enabling manufacturers to tackle both productivity and sustainability challenges head-on.

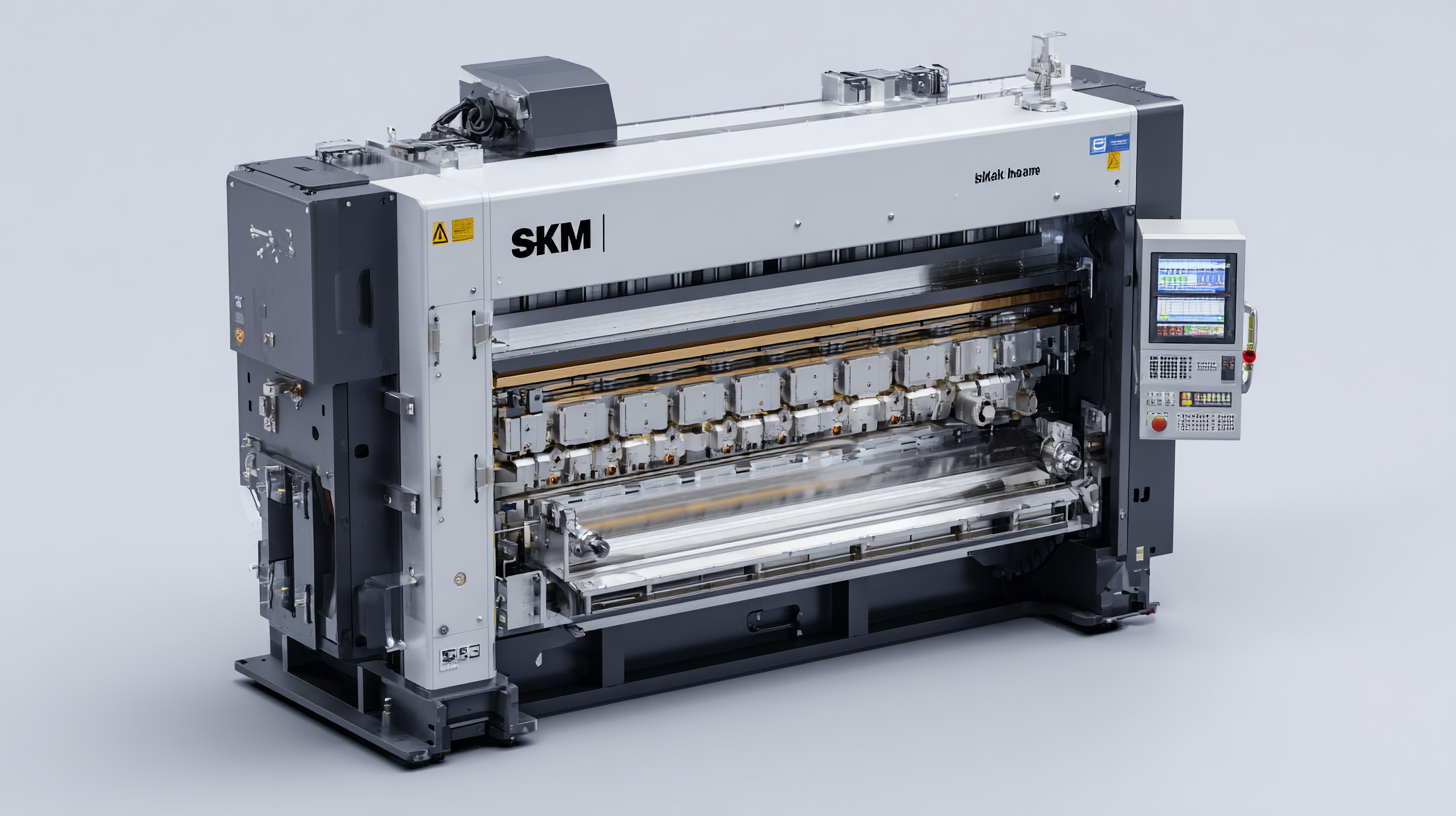

Integrating Smart Technology: AI and Automation in Press Brake Operations

As the industry steers towards 2025, the integration of artificial intelligence (AI) and automation into small hydraulic press brake technology is set to redefine manufacturing processes. With advancements in in-process monitoring methods, manufacturers can achieve enhanced precision in metal forming operations. This technology enables real-time measurement of force, geometry, and temperature, significantly improving the quality control and efficiency of production workflows.

Moreover, the evolution of automated bending machines has made programming more user-friendly, thereby allowing contract manufacturers to adopt these systems with ease. The growing trend of smart maintenance, powered by AI, will further streamline operations by predicting equipment failures and optimizing maintenance schedules. This capability not only minimizes downtime but also ensures that machinery operates at peak performance, ultimately driving productivity in press brake operations.

These innovations signal a shift toward more intelligent and interconnected manufacturing environments, where data-driven insights combined with automation propel businesses forward in a competitive global landscape. As we approach 2025, the adoption of these smart technologies in press brake applications is not just a possibility but a necessity for success in the evolving market.

Future Innovations in Small Hydraulic Press Brake Technology for 2025 Global Buyers

| Feature | Description | Benefits | Expected Launch Year |

|---|---|---|---|

| AI Integration | Utilizing artificial intelligence for enhanced precision in bending operations. | Improved accuracy, reduced waste, and higher efficiency. | 2025 |

| Remote Monitoring | Capability to monitor operations and performance remotely via IoT. | Real-time feedback and troubleshooting, leading to reduced downtime. | 2025 |

| Automated Tool Change | Automatic tool changing mechanisms to streamline production processes. | Increased productivity, reduced manual labor, and shorter cycle times. | 2025 |

| Energy Efficiency | New designs focused on reducing energy consumption during operations. | Lower operational costs and reduced environmental impact. | 2025 |

| User-Friendly Interfaces | Intuitive touchscreen controls and advanced software for operators. | Enhanced usability and reduced training time for new operators. | 2025 |

Sustainability in Hydraulic Press Brake Manufacturing: Green Innovations for 2025

As the demand for sustainable manufacturing practices increases, the small hydraulic press brake technology niche is also adopting greener innovations by 2025. Recent reports indicate that the market for eco-friendly machinery is expected to grow by over 15% annually, driven by both regulatory standards and consumer preferences for sustainable products. Manufacturers are now focusing on reducing their carbon footprint through the use of renewable materials and energy-efficient designs, ensuring that their hydraulic press brakes align with global sustainability goals.

One significant innovation is the integration of smart technologies that optimize energy consumption during operations. By utilizing advanced software that monitors hydraulic systems, manufacturers can significantly reduce hydraulic fluid use and energy wastage. A study noted that machines equipped with such technologies can save up to 30% in operational energy costs over conventional systems.

Tip: To enhance sustainability in your operations, consider investing in hydraulic press brakes with advanced energy-saving features and recycling capabilities. Always evaluate the lifecycle impact of machines before purchasing to align with your environmental goals. Another point to consider is the interest in using biodegradable hydraulic fluids, which can minimize environmental hazards without compromising performance.

Future Material Use: Advancements in Fabrication for Press Brake Components

The future of small hydraulic press brake technology is poised for significant advancements, particularly in the materials used for fabrication. As manufacturers strive for increased efficiency and durability, the emphasis will shift toward lightweight, high-strength materials such as advanced alloys and composites. These innovations not only enhance the operational capabilities of press brakes but also contribute to energy savings and reduced operational costs. The use of such materials can lead to more compact designs, allowing for better space utilization in manufacturing facilities.

Additionally, advancements in fabrication techniques will revolutionize the production process of press brake components. Techniques such as additive manufacturing and precision machining are becoming more prevalent, allowing for complex geometries that were previously unattainable. These methods enable manufacturers to produce parts that are not only lighter but also tailored to specific performance requirements, improving the overall functionality of the press brakes. As the industry moves toward sustainability, eco-friendly materials and processes will also gain traction, aligning with global goals for reduced environmental impact. Embracing these innovations will undoubtedly shape the future landscape of small hydraulic press brake technology for global buyers in 2025 and beyond.

Future Innovations in Small Hydraulic Press Brake Technology: Material Advancements

This chart illustrates the projected advancements in the material use for press brake components by 2025. The data reflects the anticipated percentage of use for different materials in the fabrication of press brake parts.

The Role of User Experience in Redefining Press Brake Interfaces and Controls

As we look toward 2025, the landscape of small hydraulic press brakes is evolving, particularly in how user experience shapes their interfaces and controls. The integration of smart technology in press brakes not only amplifies precision but also enhances usability, making machines more accessible to operators of varying skill levels. By focusing on intuitive design and streamlined interfaces, manufacturers can significantly reduce the learning curve associated with these complex machines.

Tip 1: When selecting a press brake, prioritize models that feature user-friendly control panels. Look for touchscreen interfaces and programmable options that allow for quick setup and adjustments, saving time during operations.

Incorporating feedback directly from users is essential for driving innovation. By understanding the pain points experienced by operators, engineers can design interfaces that respond to real-world challenges, such as reducing repetitive movements or simplifying complex tasks. Enhanced visual displays and ergonomic controls not only boost operator comfort but also improve overall productivity.

Tip 2: Always consider the ergonomics of the machine controls. An efficient layout can minimize fatigue and maximize accuracy, ensuring that operators can maintain focus and efficiency throughout lengthy production runs.