Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

The metalworking industry is witnessing unprecedented growth, with forecasts indicating a significant expansion in demand for advanced manufacturing equipment. According to a report by MarketsandMarkets, the global hydraulic press market is predicted to reach USD 8.2 billion by 2026, growing at a CAGR of 4.3%. This surge underscores the critical role of hydraulic metal brake press solutions, particularly those developed by China's leading manufacturers. By integrating cutting-edge technology and engineering precision, these solutions not only enhance operational efficiency but also ensure unparalleled quality in sheet metal fabrication. As companies seek to remain competitive in an increasingly demanding market, the adoption of state-of-the-art hydraulic brake presses stands out as a pivotal strategy for unleashing excellence in metalworking processes.

Innovative Design and Technology in China's Hydraulic Brake Press Solutions

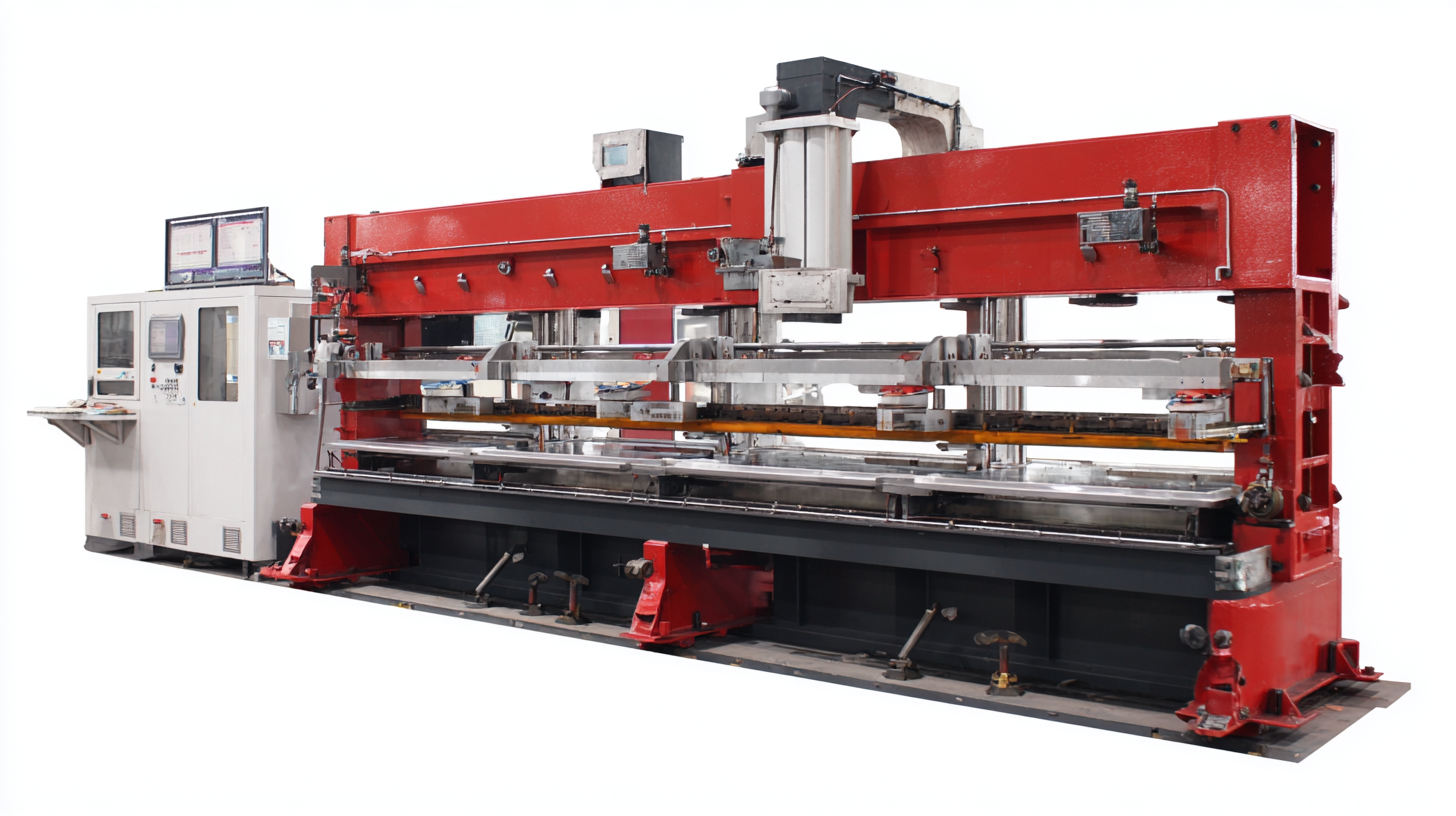

In the realm of metalworking, precision and efficiency are paramount, and China's premier hydraulic brake press solutions are at the forefront of innovative design and technology. These machines are engineered to deliver unrivaled performance, combining advanced hydraulic systems with user-friendly interfaces. Innovative features like programmable control systems enable operators to achieve precise bends and formations, elevating the standards of craftsmanship in metal manufacturing.

Moreover, the continuous improvement in hydraulic technology has paved the way for machines that not only enhance productivity but also promote sustainability. Modern hydraulic brake presses in China are designed with energy-efficient mechanisms that reduce consumption during operation, aligning with global trends towards eco-friendliness. The integration of smart technology, such as real-time monitoring and automated adjustments, ensures that manufacturers can achieve high levels of accuracy while minimizing material waste, further underscoring the industry's commitment to excellence in metalworking.

Unleashing Excellence in Metalworking with China's Premier Hydraulic Brake Press Solutions

| Specification | Value |

|---|---|

| Model Type | C-Frame Hydraulic Press |

| Max Pressure | 200 tons |

| Stroke Length | 500 mm |

| Table Size | 1000 x 600 mm |

| Weight | 2500 kg |

| Operation Type | Automatic |

| Control System | CNC |

| Power Supply | 380V, 50Hz |

The Role of Precision in Achieving Metalworking Excellence

In the competitive landscape of metalworking, precision is not just an advantage; it is a necessity. According to the latest industry report by MarketsandMarkets, the global hydraulic press market is expected to reach USD 6.4 billion by 2026, driven by the demand for accurate and efficient metal forming processes. These statistics reinforce the importance of investing in advanced hydraulic brake press solutions that enable manufacturers to achieve high levels of precision, ensuring tighter tolerances and superior product quality.

Tip: Regular calibration and maintenance of hydraulic brake presses are crucial for maintaining precision. Setting a schedule for routine checks can help in identifying potential issues before they affect production quality.

Moreover, precision in metalworking not only enhances production efficiency but also reduces material waste. A study by Deloitte Insights found that enhancing precision can lead to a 25% decrease in scrap rates, significantly lowering operational costs. As manufacturers adopt China's premier hydraulic brake press solutions, they are better positioned to capitalize on these benefits and meet the rigorous demands of today’s market.

Tip: Implementing a robust quality control system can further improve precision rates. Employing tools such as statistical process control (SPC) can help monitor variations and maintain consistent quality throughout the production cycle.

Exporting Quality: How Chinese Manufacturers Compete Globally

Chinese manufacturers have long been at the forefront of the global metalworking industry, and their

advanced hydraulic brake press solutions exemplify this trend. By leveraging

state-of-the-art technology and rigorous quality control measures, they not only meet domestic

demands but also excel in international markets. The integration of precision engineering with robust

manufacturing processes enables these companies to produce machines that enhance productivity and drive

down operational costs for their global clients.

In the competitive landscape of metalworking, the ability to export high-quality

hydraulic brake presses is crucial. Chinese manufacturers focus on innovation and

customer-centric designs, ensuring that their products cater to a

diverse range of industries. By securing certifications and adhering to international standards, they build

trust with global partners. This commitment to quality and excellence

not only boosts their reputation but also positions Chinese manufacturers as key players in the global

supply chain, ready to meet the evolving needs of the markets they serve.

Sustainability and Efficiency in Modern Metalworking Practices

In today’s rapidly evolving metalworking industry, sustainability and efficiency are no longer luxuries but necessities. As manufacturers seek to reduce their carbon footprints, China’s premier hydraulic brake press solutions have emerged as pivotal tools in achieving these goals. These modern machines integrate advanced technologies that optimize energy consumption while delivering unparalleled precision and power. By utilizing hydraulic systems that minimize waste and enhance performance, metalworkers can produce high-quality components with significantly lower environmental impact.

Moreover, the implementation of sustainable practices through advanced hydraulic brake presses fosters a culture of resource conservation. These presses are designed to utilize recyclable materials and reduce manufacturing waste, aligning perfectly with global sustainability initiatives. The efficiency gained from these machines not only streamlines production processes but also ensures that operations remain competitive in the ever-challenging market. As metalworking continues to focus on sustainable practices, hydraulic brake presses represent a transformative shift towards a greener future in the industry.

Case Studies: Success Stories of Hydraulic Brake Press Users Worldwide

In the competitive landscape of metalworking, hydraulic brake presses have emerged as essential tools for achieving precision and efficiency. Case studies from users around the globe reveal significant success stories enabled by these premier solutions. From the automotive industry to heavy machinery manufacturing, companies leveraging hydraulic brake presses report enhanced productivity, reduced operational costs, and improved product quality.

For instance, in Europe, a leading automotive manufacturer integrated advanced hydraulic brake presses into their production line, resulting in a 30% increase in output and a dramatic decrease in material waste. Similarly, a metal fabrication company in Asia tailored its hydraulic solutions to accommodate varying project specifications, thus allowing for greater flexibility and responsiveness to market demands.

These success stories highlight the pivotal role hydraulic brake presses play in empowering manufacturers to achieve excellence, adapt to industry shifts, and meet the rigorous standards expected in today’s market.