Unlocking Efficiency and Precision: The Advantages of the Best Metal Shear Machine

In today's fast-paced manufacturing environment, the demand for precision and efficiency has never been higher, particularly in the metalworking industry. The global metal shear machine market is projected to reach USD 2.5 billion by 2025, growing at a CAGR of 4.2% from 2020, as reported by Market Research Future. This significant growth underscores the increasing reliance on advanced metal shear machines that enhance operational productivity and ensure precision in cutting metal sheets.

As manufacturers strive to achieve higher standards of quality while reducing production costs, investing in state-of-the-art metal shear technology becomes critical. By harnessing the capabilities of the best metal shear machines, companies can not only streamline their operations but also gain a competitive edge in an increasingly globalized market. "中国优质制造,您的全球合作伙伴" signifies the commitment to quality manufacturing that supports this evolution, catering to businesses worldwide.

Understanding the Fundamentals of Metal Shear Machines: Types and Technologies

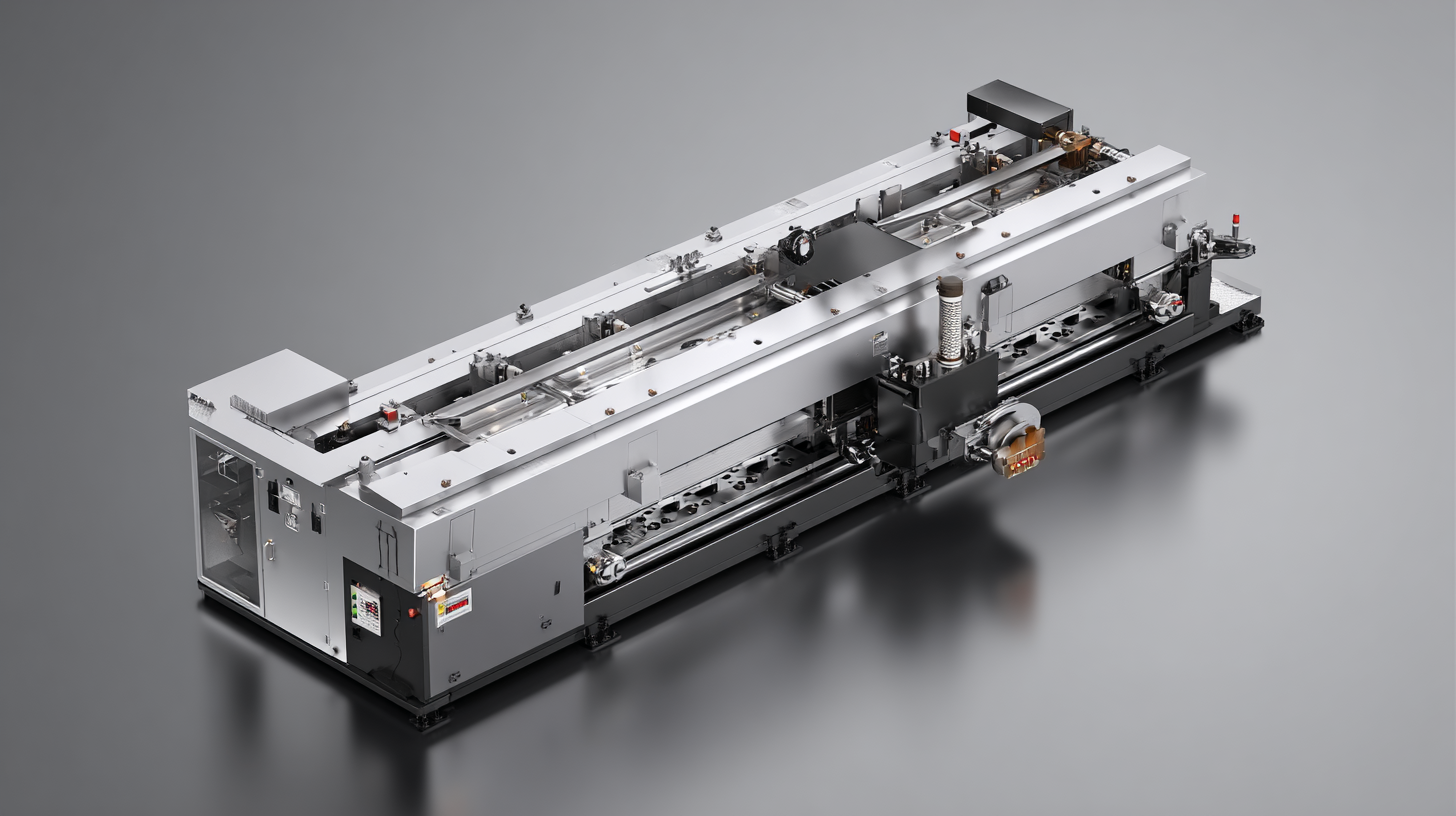

Metal shear machines are essential tools in the metalworking industry, designed to efficiently cut materials with precision. Understanding the fundamentals of these machines, including their types and technologies, is crucial for maximizing their benefits. The primary types of metal shears include mechanical, hydraulic, and pneumatic shear machines, each offering unique advantages. Mechanical shears are known for their speed and are often used in high-volume applications. Hydraulic shears, on the other hand, provide greater cutting force and are ideal for thicker materials, making them suitable for industries that require heavy-duty performance.

Technological advancements have significantly enhanced the capabilities of metal shear machines. Modern models often incorporate computer numerical control (CNC) technology, allowing for automated precision cutting and reducing human error. Additionally, innovations in blade design and materials have improved cutting efficiency, extending the lifespan of the blades and reducing maintenance needs. Understanding these types and technologies empowers manufacturers to select the best metal shear machine that aligns with their production requirements, ultimately enhancing operational efficiency and cutting accuracy in their processes.

Key Benefits of Using Advanced Metal Shear Machines in Manufacturing Processes

In the manufacturing landscape, advanced metal shear machines play a pivotal role in enhancing both efficiency and precision. These machines provide unparalleled cutting capabilities that are essential for producing high-quality components, particularly in industries such as automotive and aerospace. By integrating state-of-the-art technology, these shears reduce production time and waste while maintaining exact material dimensions, which is crucial for meeting stringent industry standards.

Moreover, the current shift towards advanced manufacturing techniques, including the incorporation of automation and smart technologies, is reinforcing the value of using sophisticated metal shear machines. Innovations in combined punching and shearing systems demonstrate how modern machinery can effectively optimize workflow, allowing manufacturers to achieve higher productivity levels. The ability to accurately process complex geometries and materials not only streamlines operations but also supports sustainable practices by minimizing scrap rates and resource consumption. As manufacturing processes evolve, the benefits of investing in advanced metal shear technology become increasingly apparent, laying the groundwork for a more efficient and precise future.

Analyzing Industry Statistics: Increased Efficiency Metrics with Modern Shear Machines

In today's fast-paced manufacturing industry, the introduction of modern shear machines has revolutionized metal processing. Industry statistics reveal significant improvements in efficiency metrics, showcasing the transformative impact of these machines. From reducing cutting time to minimizing material waste, advancements in technology allow for precision that was once unattainable. Businesses leveraging modern shear machines report up to 30% increase in operational productivity, directly contributing to their bottom line.

To maximize the benefits of these machines, consider implementing regular maintenance checks to ensure optimal performance. A well-maintained shear machine not only functions smoothly but also extends its longevity, preventing costly downtimes. Additionally, invest in training for your operators to familiarize them with the latest technologies and techniques. This not only enhances safety but also empowers your team to achieve higher quality outputs.

Moreover, integrating automation with shear machines can further enhance efficiency. Automated systems reduce human error and allow for consistent cuts, resulting in more precise outcomes. By keeping abreast of industry advancements and continually optimizing your processes, your business can stay competitive while reaping the rewards of modern manufacturing technologies.

Precision Cutting: How Top Metal Shear Machines Improve Product Quality and Reduce Waste

When it comes to metal fabrication,

precision cutting

is paramount in ensuring that the final product meets quality standards. The best

metal shear machines are designed to deliver immaculate cuts, significantly enhancing the overall product quality.

With features like adjustable blade gaps and advanced cutting technology, these machines minimize discrepancies and

ensure uniform dimensions, which is critical for projects requiring high accuracy.

Tip 1:

Regular maintenance of your shear machine is key to preserving its cutting precision.

Ensure that blades are sharpened frequently and check alignment to avoid any potential cutting errors.

Moreover, using top-tier metal shear machines can significantly reduce material waste.

With enhanced cutting capabilities, less scrap material is produced during the cutting process.

This not only saves costs but also contributes to a more sustainable operation

by reducing wasted resources.

Tip 2:

Optimize your cutting plans by using nesting software, which can help you arrange pieces efficiently

to maximize material usage and minimize waste. This clever method can drastically improve productivity

and resource management.

Best Practices for Selecting the Right Metal Shear Machine for Your Business Needs

When selecting a metal shear machine for your business, it’s crucial to assess your specific needs before making a decision. Start by evaluating the types and thicknesses of materials you work with. Different machines are designed for varying levels of hardness and thickness; therefore, understanding your material's requirements will help you narrow down options and avoid investing in a machine that is either underpowered or overly complex for your tasks.

Another important consideration is the machine's capacity and size. Ensure that the shear machine you choose fits seamlessly into your workspace and has the capability to handle the volume of work you expect to produce. Additionally, look for features that enhance precision and efficiency, such as adjustable cutting angles and automated feed systems. This attention to detail will not only increase productivity but also minimize waste, making your operation more cost-effective in the long run.

Lastly, don’t overlook the importance of manufacturer support and warranty options. A reputable supplier will provide not only high-quality equipment but also ongoing maintenance and training resources. Consider reading customer reviews and seeking recommendations to ensure that you choose a machine that comes with solid backing and a good reputation in the industry. These best practices will guide you toward selecting the right metal shear machine that aligns with your operational goals.

Unlocking Efficiency and Precision: The Advantages of the Best Metal Shear Machine

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Cutting Capacity | Maximum thickness and material type the shear can cut. | Ensures the machine meets production needs. | Match cutting capacity with the materials used in your business. |

| Blade Type | Types of blades available (e.g., straight, rotary, guillotine). | Improved cutting quality and longevity. | Choose a blade compatible with your specific metal types. |

| Automation Features | Presence of automated controls and features. | Increased productivity and reduced labor costs. | Evaluate the trade-off between cost and efficiency. |

| Portability | Size and weight of the machine for mobility. | Flexibility to move the machine as needed. | Consider workspace layout and future needs. |

| Safety Features | Incorporation of guards, emergency stops, and safety locks. | Reduction of workplace accidents. | Ensure compliance with industry safety standards. |