How to Effectively Use a Manual Press Machine for Optimal Results

In today's manufacturing landscape, the effective use of a manual press machine has become increasingly crucial for achieving optimal results in production processes. According to a report by the National Association of Manufacturers, over 68% of manufacturers recognize the importance of precision and efficiency in their operations, which can be substantially enhanced through the correct application of manual pressing techniques.

Manual press machines, known for their versatility and reliability, play a vital role in various industries, from metalworking to crafting, enabling operators to create high-quality products with precision. As the demand for customized and intricate designs rises, mastering these machines is essential for professionals aiming to maintain competitive edge and meet client expectations.

This article will explore practical tips and techniques for maximizing the performance of your manual press machine, ensuring you achieve the best results possible in your projects.

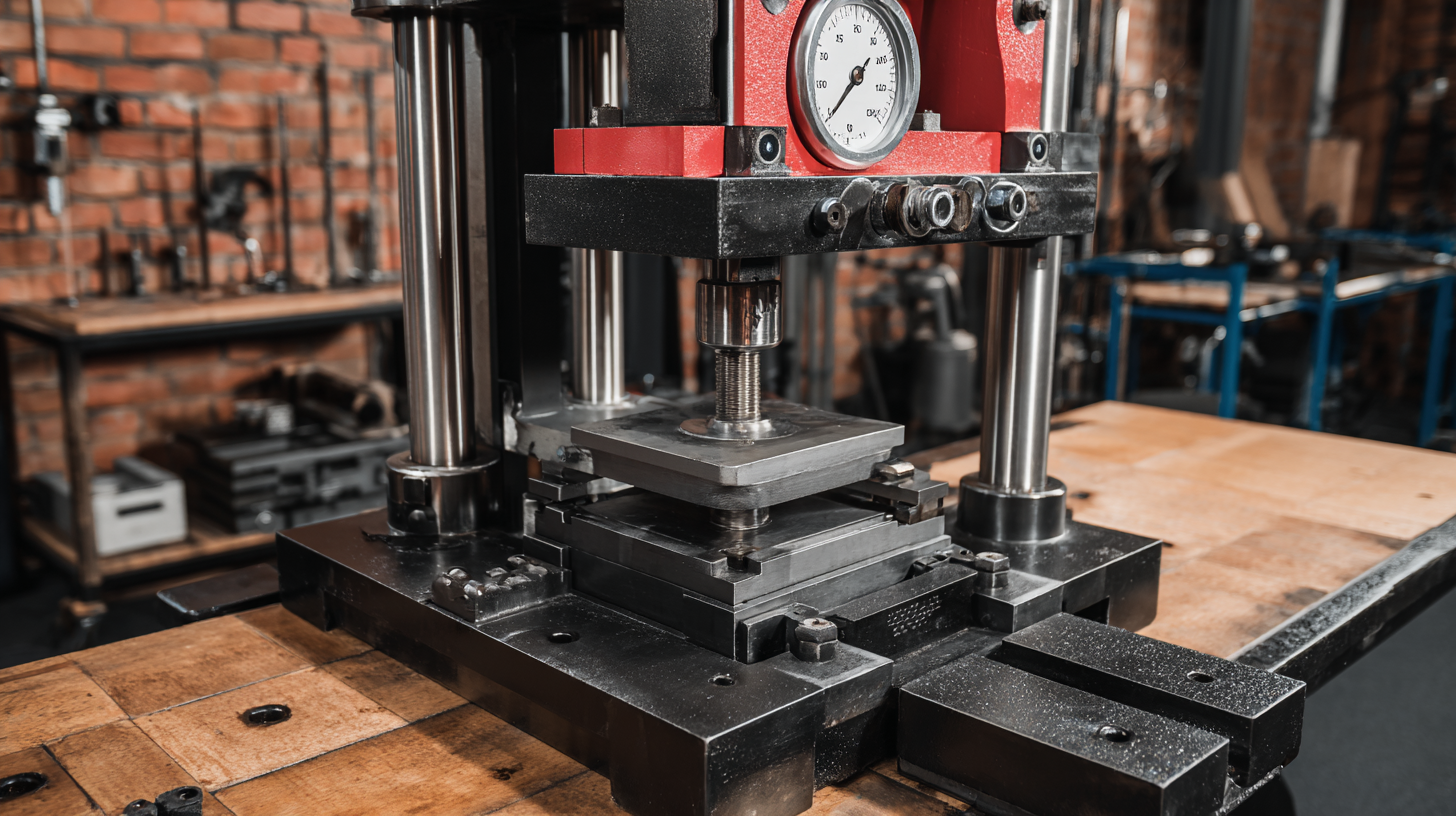

Understanding the Basics of a Manual Press Machine and Its Components

A manual press machine is a versatile tool used in various industries for shaping, cutting, and forming materials. Understanding its fundamental components is essential for maximizing its efficiency and longevity. Key components of a manual press machine include the frame, which provides structural support; the ram, which delivers force to the material; and the die, which defines the shape of the finished product. Each part plays a vital role in the machine's operation, influencing the precision and quality of the output.

To operate a manual press machine effectively, one must familiarize themselves with these components and their functions. The frame should be stable and securely anchored to prevent any wobbling during operation. The ram's movement must be smooth and controlled, allowing for consistent pressure application. Selecting the correct die is crucial, as it directly affects the accuracy of the cut or shape produced. Regular maintenance checks on components, such as lubricating moving parts and inspecting for wear, can further enhance the machine's performance, ensuring optimal results with every use.

Setting Up Your Manual Press Machine for Peak Performance

Setting up your manual press machine for peak performance involves several critical steps that can significantly enhance its efficiency. According to a recent industry report by the National Association of Manufacturers (NAM), ensuring the proper alignment and calibration of your machine can improve output quality by up to 30%. Begin by confirming that the press is situated on a stable, level surface, which reduces vibrations and maintains accurate pressure application during operation.

Additionally, maintaining the ideal temperature and humidity in the workspace is vital. A study published in the Journal of Manufacturing Science and Engineering indicates that fluctuations in environmental conditions can lead to material expansion or contraction, affecting the consistency of the pressing results. Keeping the press in a controlled environment not only prolongs the lifespan of the equipment but also minimizes defects in the finished product.

Regularly inspecting and lubricating the moving parts of the machine will support smooth operation, with research showing that well-maintained machinery performs an average of 15% better than poorly maintained counterparts.

Techniques for Loading and Aligning Materials for Consistent Results

Loading and aligning materials properly in a manual press machine is crucial for achieving consistent results. Start by ensuring that the materials you will be using are clean and free from any debris. This step is essential as dirt or irregularities can lead to uneven pressure during the pressing process. When loading the material, make sure to place it flat and correctly into the press bed, aligning it with the machine's reference points to ensure uniformity.

Next, it's important to check the alignment of the materials. Gently adjust them to ensure that they are centered in relation to the press's surface. This can often be achieved by using guides or positioning tools specific to the press machine. Taking the time to precisely align your materials will significantly reduce the risk of mispressing, which can lead to defects or structural problems in the final product. Consistency in loading and aligning will not only improve the quality but also enhance the efficiency of your pressing operations.

How to Effectively Use a Manual Press Machine for Optimal Results

| Technique | Description | Recommended Material | Expected Outcome |

|---|---|---|---|

| Proper Loading | Load materials evenly to avoid imbalances. | Metal sheets, plastic films | Consistent pressure application |

| Material Alignment | Align materials with the press guide for stability. | Cardboard, composite materials | Reduced waste and improved accuracy |

| Pressure Adjustment | Adjust pressure settings based on material thickness. | Thin sheets, foams | Enhanced material integrity |

| Temperature Control | Monitor temperature for heat-sensitive materials. | Thermoplastics, rubber | Improved bonding and reduced defects |

| Cycle Time Management | Optimize cycle times for efficiency. | Various materials | Maximized production output |

Maintaining Your Manual Press Machine for Long-lasting Efficiency

Maintaining your manual press machine is essential for ensuring long-lasting efficiency and optimal performance. According to industry reports, machines that are properly maintained can last 20-30% longer than those that are neglected. Regular inspection and routine maintenance not only extend the life of the equipment but also enhance productivity, reducing downtime and repair costs.

To maintain your manual press machine, start with routine cleaning. Dust and debris can accumulate and affect the machine's performance. Use a soft cloth to wipe down surfaces and ensure that any moving parts are lubricated according to the manufacturer's guidelines. Additionally, consider checking the alignment and tensioning of components periodically, as misalignment can lead to unnecessary wear and tear.

Tips:

- Schedule regular maintenance checks every 3-6 months to catch potential issues early.

- Keep a maintenance log to track repairs and servicing, which can improve accountability and ensure adherence to schedules.

- Invest in quality lubricants and cleaning supplies, as they can significantly impact the performance and longevity of your machine.

Common Mistakes to Avoid When Operating a Manual Press Machine

When operating a manual press machine, avoiding common mistakes can significantly enhance both safety and efficiency. One prevalent error involves improper alignment of materials. According to a report by the American Society of Mechanical Engineers, misalignment can lead to a safety risk and produce subpar results, with rejection rates soaring to 30% in poorly aligned presses. Ensuring that components are aligned correctly before beginning operations is crucial for achieving optimal performance.

Another frequent mistake is neglecting regular maintenance. The International Journal of Automotive Technology highlights that regular maintenance can extend the lifespan of machinery by up to 50%. This includes routine checks of wear and tear and ensuring that all moving parts are properly lubricated. Failing to maintain your press can lead to costly downtimes and repair expenses, which can be easily avoided with a proactive maintenance schedule.

Tips: Always double-check the alignment of your materials before pressing and establish a clear maintenance routine. Additionally, educating your team about proper operational protocols can significantly reduce errors and enhance productivity. Regular training sessions can keep safety standards high while maximizing the efficacy of your manual press machine.

Related Posts

-

15 Reasons Why the Best Press Machine Can Transform Your Production Process

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

What is the Importance of Manual Press Machines in Modern Manufacturing

-

Comprehensive Manual Press Machine Guide: Everything You Need to Know for Optimal Use

-

Unlocking Efficiency and Precision: The Advantages of the Best Metal Shear Machine

-

Unlocking Precision: The Best Press Brake Machines from China’s Premier Manufacturing Factory