Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs

In the rapidly evolving landscape of manufacturing technology, selecting the right equipment is crucial for efficiency and productivity. One such indispensable tool is the hydraulic press brake machine, which plays a vital role in sheet metal forming processes across various industries. As we look towards the trends shaping our industry in 2025, it’s essential to understand what features and specifications to prioritize when choosing a hydraulic press brake machine that meets your specific needs. From advancements in automation and control systems to the importance of precision and safety features, this ultimate guide aims to equip you with the knowledge necessary to make an informed decision. Whether you're a seasoned professional or new to the field, ensuring you select the best hydraulic press brake machine will significantly impact your operational success and bottom line.

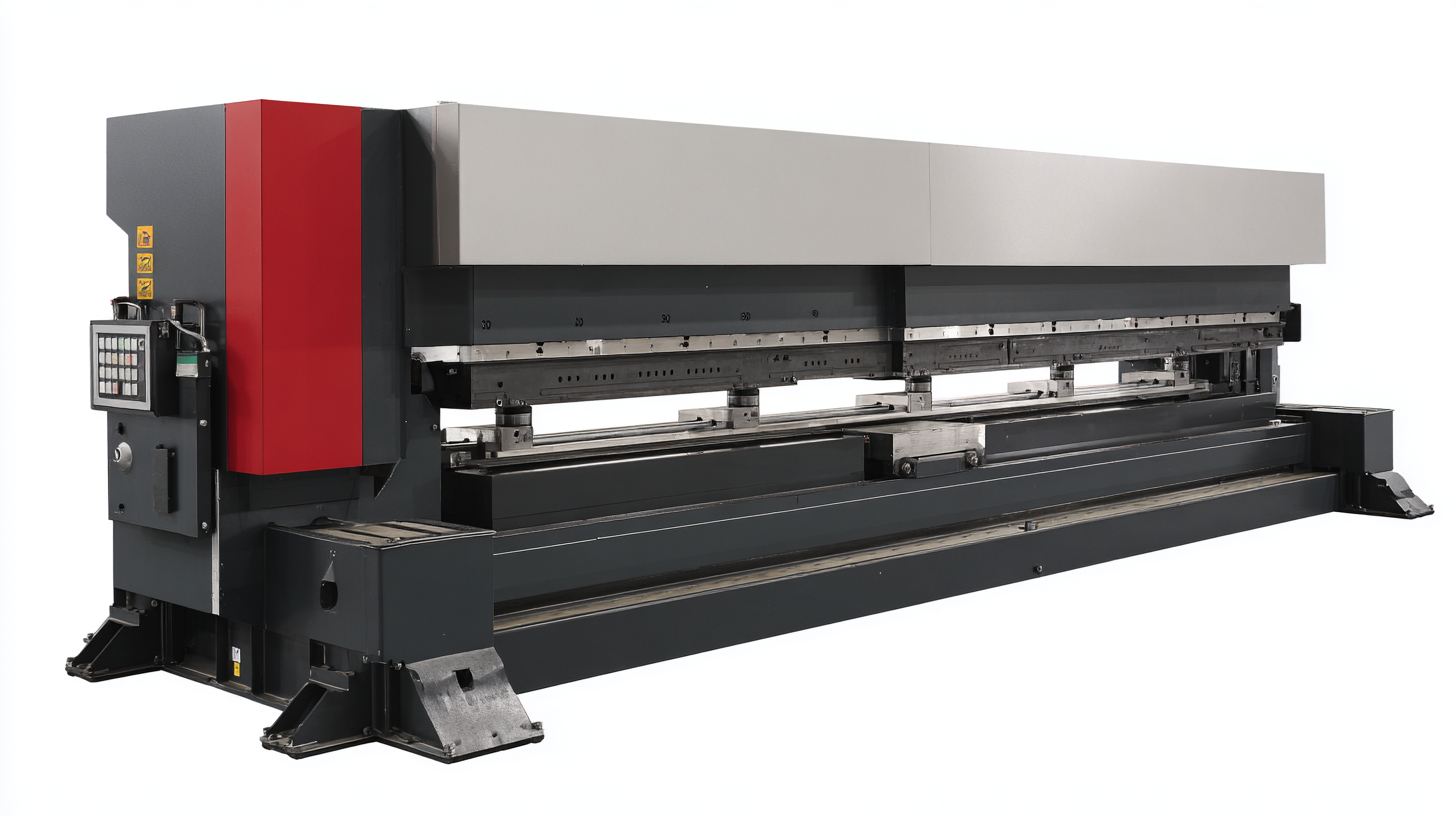

Key Factors to Consider When Selecting a Hydraulic Press Brake Machine

When selecting a hydraulic press brake machine, several key factors should be prioritized to ensure optimal performance and suitability for your specific needs. Firstly, consider the type of material you will be working with, as material type and thickness play a vital role in the bending and folding applications. Different materials, such as steel or aluminum, may require different machine specifications, including force and bending capabilities.

Another essential factor is the drive system of the press brake. Research indicates that modifying a constant speed-driven hydraulic press brake machine into a variable speed drive system can enhance electricity savings while maintaining performance efficiency. This transition could significantly impact your operational costs over time, making it a crucial element in your decision-making process. Understanding the machine's mechanisms, including hydraulic circuit designs, can also aid in assessing its potential sustainability in your production environment. By thoughtfully evaluating these factors, you can choose a hydraulic press brake machine that aligns perfectly with your manufacturing goals.

Understanding Different Types of Hydraulic Press Brake Machines

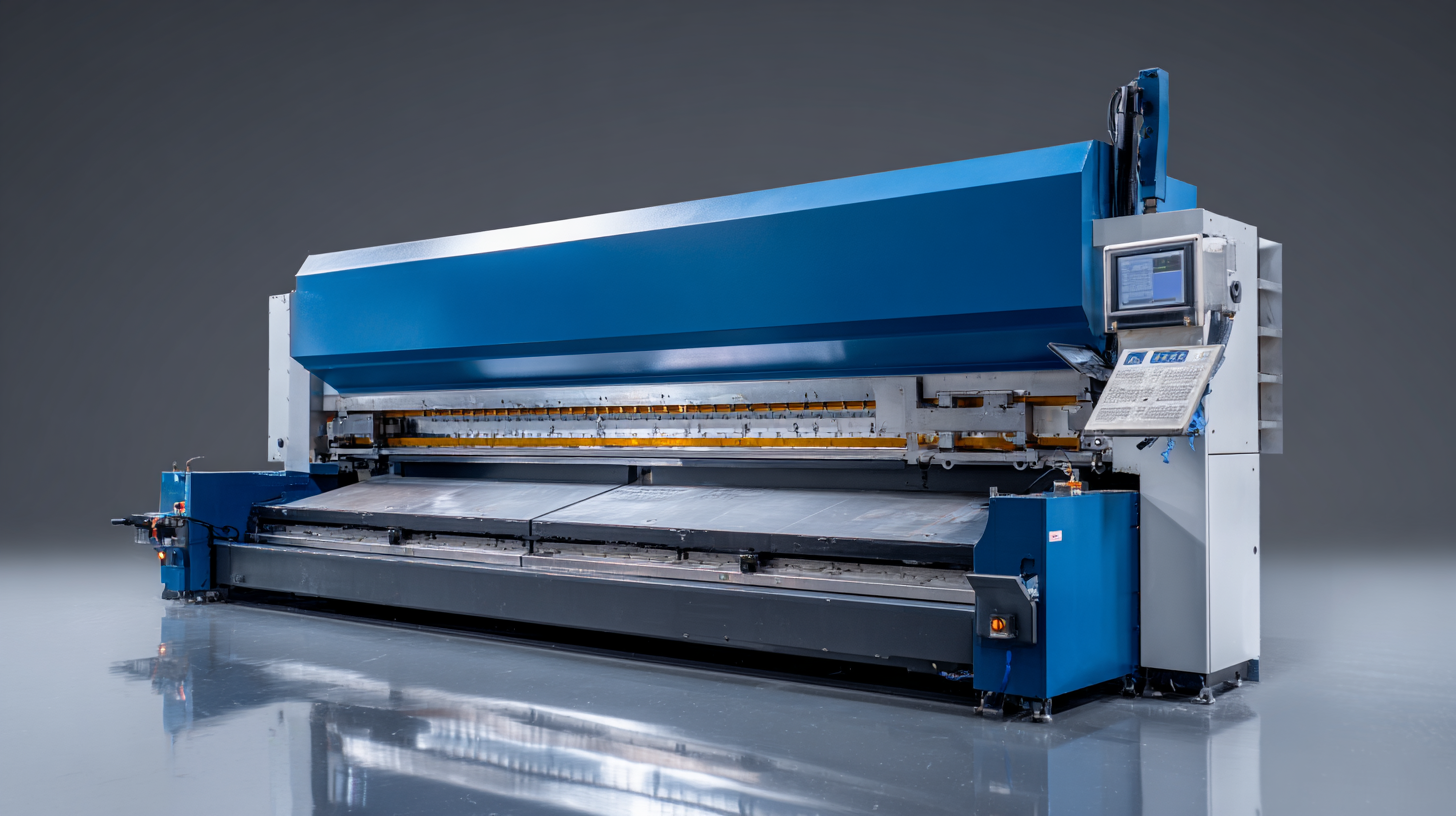

When selecting a hydraulic press brake machine, it's essential to understand the various types available on the market. Each type serves different purposes and comes with unique features that cater to specific applications. The most common types include the mechanical, hydraulic, and servo-electric press brakes. Mechanical press brakes use a flywheel and are known for their speed and precision, making them suitable for lighter materials and thinner sheets. However, they may not be ideal for heavier-duty jobs where more force is required.

On the other hand, hydraulic press brakes deliver a significant amount of bending force and are versatile enough to handle various materials, including thicker sheets. They operate using fluid power, allowing for uniform force distribution, which results in precise bends. Servo-electric press brakes, while less common, combine the benefits of electric and hydraulic systems, providing exceptional energy efficiency and precision. Understanding these differences will help you select the most appropriate hydraulic press brake machine that meets your specific production needs.

Essential Features to Look for in a Quality Hydraulic Press Brake

When selecting a quality hydraulic press brake machine, it’s essential to focus on its key features that will meet your specific needs. First and foremost, consider the machine's tonnage capacity, as it determines the maximum weight it can bend. For heavier materials, a higher tonnage is crucial, while lighter materials may require less. Additionally, look for a machine that offers adjustable bending speeds and stroke length, ensuring flexibility and efficiency for different projects.

Another critical aspect is the control system. Modern hydraulic press brakes often come with CNC (Computer Numerical Control) technology, enhancing precision and repeatability in operations. A user-friendly interface will allow operators to program complex bends with ease. Moreover, pay attention to the construction quality and safety features, such as an emergency stop function and protective guards, which are vital for a safe working environment. By prioritizing these essential features, you can choose a hydraulic press brake that enhances productivity and delivers reliable performance for various applications.

Top Brands and Manufacturers of Hydraulic Press Brake Machines

When it comes to selecting a hydraulic press brake machine, understanding the top brands and manufacturers can significantly impact your decision. Renowned companies like Amada, Trumpf, and Bystronic are known for their innovative technology and reliability. These brands offer a range of models catering to various production needs, from small workshops to large manufacturing plants. Amada, for instance, is recognized for its precision engineering and user-friendly interfaces, while Trumpf stands out for its automation capabilities.

Tip: Before making a purchase, research each brand's customer service support and warranty options. A strong after-sales service can ensure that any technical issues are addressed promptly, minimizing downtime.

Additionally, consider the specific features each manufacturer offers. For example, Bystronic machines are often praised for their energy efficiency and advanced safety features. Determine the essential functionalities you need—like bending capacity or programmable controls—to help narrow down your choices.

Tip: Visit trade shows or expos to see these machines in action. Direct interaction with the equipment can provide valuable insights into their performance and usability, enabling you to make a more informed choice.

Ultimate Guide to Choosing the Best Hydraulic Press Brake Machine for Your Needs

| Feature | Details |

|---|---|

| Type | CNC, Mechanical, Hydraulic |

| Tonnage | 20 to 1000 tons |

| Bending Capacity | Up to 12 feet |

| Control System | Standard Manual, NC, or PC |

| Weight | Varies by model: 2000 to 8000 kg |

| Overall Dimensions | Standard dimensions around 3000x1500x2000 mm |

| Power Supply | 220V, 380V or custom based on region |

| Accessories | Die sets, Back gauge, Foot pedal |

| Warranty | 1-3 years depending on the manufacturer |

| Price Range | $5,000 - $200,000 |

Tips for Budgeting and Cost-Effective Purchasing of Hydraulic Press Brakes

When considering the purchase of a hydraulic press brake machine, budgeting effectively is essential for making a cost-effective choice. Begin by determining the specific needs of your operations, as different models come with varying features and price tags. Identify the key specifications you require—such as bending capacity, size, and versatility—while keeping in mind that investing in a machine that offers the best value for your intended workload can lead to significant long-term savings.

To maximize your budget, explore second-hand options or consider machines that are known for their reliability and long-lasting performance. Just like the affordable full-suspension bikes that offer great entry-level features for mountain biking, there are hydraulic press brakes designed to deliver efficient performance without breaking the bank. Take the time to compare prices, read reviews, and seek advice from industry peers to ensure you find a model that meets your needs without compromising on quality. Emphasizing a balance between cost and functionality will ultimately allow you to invest wisely while ensuring efficient operations for your business.