How to Choose the Best Laser Cutting Machine for Your Needs?

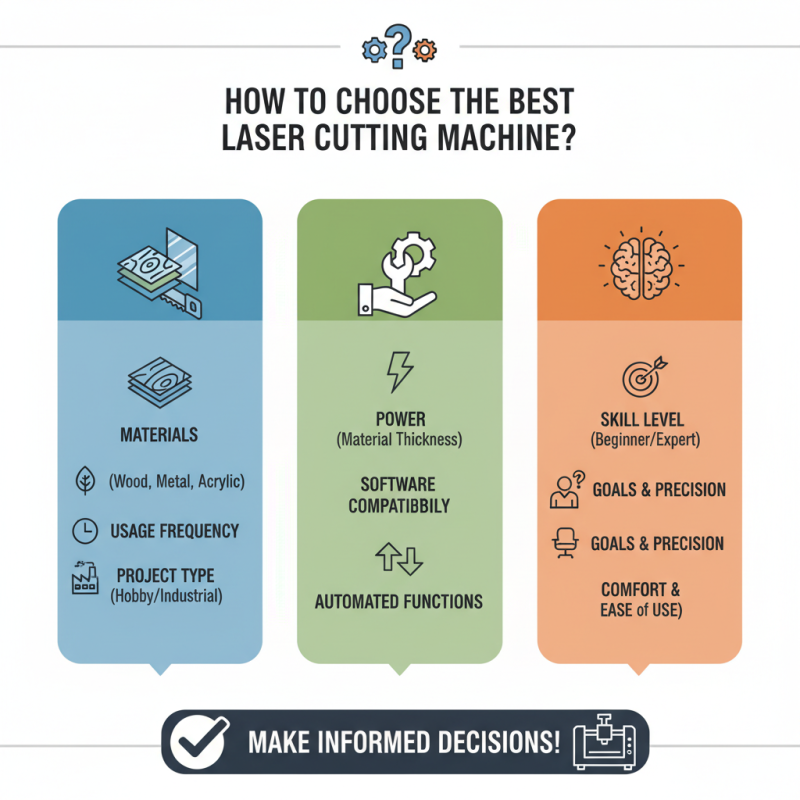

Choosing the right laser cutting machine can be a daunting task. With numerous options available, it's easy to feel overwhelmed. The right machine can elevate your projects, enhance precision, and improve workflows. However, it's crucial to understand your specific needs before making a decision.

Different materials require different settings and capabilities. For instance, wood, metal, and acrylic each have unique cutting requirements. Consider how often you’ll use the machine and the materials you’ll work with. These factors can greatly influence your final choice. A more powerful machine may be needed for metalwork, while simpler versions suffice for hobby projects.

Also, reflect on additional features. Some machines offer advanced technology, like software compatibility or automated functions. While these can be beneficial, they may also complicate usage for beginners. Evaluate your skill level and whether the extra features are truly necessary. Ultimately, selecting a laser cutting machine should align with your goals and comfort level.

Understanding the Basics of Laser Cutting Technology

Laser cutting technology has revolutionized various industries, offering precision and efficiency. The process uses focused laser beams to cut materials such as metal, wood, and plastics. According to industry reports, the global laser cutting market is expected to reach $5.5 billion by 2027, demonstrating a compound annual growth rate of 6.4%. This growth reflects the increasing adoption of laser technology across sectors, from automotive to manufacturing.

Understanding how laser cutting works is essential for making informed decisions. The technology involves the conversion of electrical energy into a laser beam. This beam melts or vaporizes the material at a targeted spot. Factors like power, speed, and wavelength impact the cutting quality. For instance, a higher wattage results in faster cutting. However, this may compromise edge quality. Many users find it challenging to balance speed and precision. This can lead to potential waste or defective products if not carefully monitored.

It is vital to evaluate your specific needs when selecting a machine. Consider the materials you'll work with and the required thickness. Customization options may enhance performance for unique applications. However, these can also complicate the operation. Misunderstanding machine capabilities can lead to underutilization or excessive overspending. Identifying your priorities is key to achieving optimal results in laser cutting projects.

Laser Cutting Machine Power Comparison

This chart compares the cutting speed of laser cutting machines with varying power levels. As the power increases, the cutting speed also tends to increase, which can significantly affect production efficiency.

Assessing Your Specific Cutting Needs and Applications

When choosing a laser cutting machine, understanding your specific cutting needs is crucial. A report by MarketsandMarkets indicates that the laser cutting market is projected to reach $4.5 billion by 2026. This growth highlights diverse applications in industries such as automotive, aerospace, and electronics. Each sector has unique requirements. For instance, the automotive industry often needs precise cuts in various materials like metals and plastics.

Assessing your materials is essential. Different lasers, such as CO2 or fiber lasers, excel in cutting specific materials. CO2 lasers work well with non-metals like wood and acrylics, while fiber lasers are ideal for metals. According to a study by Research and Markets, 35% of manufacturers report challenges in selecting the right machine. This data emphasizes the need for careful consideration.

It’s vital to reflect on future needs, too. A machine that meets current demands may not support future expansions. Investing in a machine without evaluating long-term objectives can lead to limitations. Industrial advancements may quickly outdate your purchase, prompting another investment soon after.

Key Features to Consider in a Laser Cutting Machine

When choosing a laser cutting machine, consider the power and speed. Higher wattage means faster cutting, especially in thicker materials. A machine with adjustable speed allows for precision work. While speed is essential, an overly fast machine may sacrifice quality. It's crucial to find a balance that suits your projects.

Another important feature is the bed size. Larger beds accommodate bigger materials. However, a smaller machine may suit hobbyists better. If you plan to cut various sizes, ensure the bed can handle different dimensions. Also, note the type of optics used. Better optics can improve cutting accuracy but may come at a higher cost.

Lastly, software compatibility cannot be overlooked. User-friendly software enhances productivity. Some machines come with proprietary software, which limits flexibility. A versatile machine should support multiple design formats. Don’t forget to consider customer support as well; it can make a difference in your operational efficiency.

Comparison of Different Types of Laser Cutting Machines

When selecting a laser cutting machine, understanding the types available is crucial. CO2 lasers are popular for cutting non-metal materials like wood or acrylic. They offer high precision and are often user-friendly. Reports indicate that CO2 lasers comprise about 40% of the laser cutting market in 2022. Their effectiveness in engraving and cutting thin materials makes them a go-to option for small businesses and artisans.

On the other hand, fiber lasers are growing in popularity, especially for metal cutting. Their ability to cut through thick metals quickly has attracted industries seeking efficiency. According to industry data, fiber lasers have seen a growth rate of 15% per year. However, they may not perform as well with non-metal materials. This limitation could pose challenges for users who need versatility.

Before making a choice, reflect on your specific needs. Consider the materials you'll work with and the types of projects you plan. Finding a perfect fit isn't always straightforward. Many users report struggling with machine specifications that don’t meet their long-term goals. Balancing initial costs with efficiency and capability is often a complex decision.

Budgeting for Your Laser Cutting Machine Investment

Budgeting for a laser cutting machine can be challenging. It's essential to start with a realistic budget that considers not just the purchase price but also additional costs. Think about maintenance, software, and consumables. These can add up quickly and impact your overall investment.

When determining your budget, consider the materials you plan to cut. Different machines work better with specific substrates. For example, some excel at cutting wood, while others handle metals better. If you find your needs expanding, a higher upfront cost may actually save money in the long run.

Don't forget to factor in your space and electrical requirements. A powerful machine may need a dedicated circuit. Sometimes, these factors can lead to unexpected expenses. If you need to redesign your workspace, it could strain your budget further. Keep all these aspects in mind to create a thorough and realistic plan.

How to Choose the Best Laser Cutting Machine for Your Needs? - Budgeting for Your Laser Cutting Machine Investment

| Feature | Entry-Level Machine | Mid-Range Machine | High-End Machine |

|---|---|---|---|

| Price Range | $2,000 - $5,000 | $5,000 - $15,000 | $15,000+ |

| Cutting Area (mm) | 300 x 200 | 600 x 400 | 1200 x 800 |

| Laser Power (W) | 40W | 80W | 150W |

| Materials Supported | Wood, Acrylic | Wood, Acrylic, Fabric, Leather | Wood, Acrylic, Fabric, Leather, Metal |

| Software Compatibility | Basic CAD Software | Advanced CAD & CAM Software | Professional CAD & CAM Software |

| Support & Warranty | 1 Year Limited | 2 Years Limited | 3 Years Limited + On-Site Support |