15 Best Shear Press Machines for Maximum Efficiency in Manufacturing

In today's manufacturing landscape, efficiency is paramount, and the choice of machinery plays a crucial role in achieving optimal productivity. Among the most essential tools in this domain is the shear press, renowned for its ability to precisely cut metals and other materials with minimal waste.

According to a recent report by MarketsandMarkets, the global metal fabrication machinery market is expected to grow to USD 115 billion by 2025, driven by the increasing demand for automation and efficiency in production processes. As manufacturers strive to maximize output while reducing costs, investing in high-performance shear press machines becomes vital.

According to a recent report by MarketsandMarkets, the global metal fabrication machinery market is expected to grow to USD 115 billion by 2025, driven by the increasing demand for automation and efficiency in production processes. As manufacturers strive to maximize output while reducing costs, investing in high-performance shear press machines becomes vital.

This blog will provide an insightful guide to the 15 best shear press machines available today, focusing on key features, specifications, and tips to enhance operational efficiency, ultimately elevating manufacturing standards across various industries.

Key Features to Consider When Choosing a Shear Press Machine

When selecting the ideal shear press machine for your manufacturing needs, it's crucial to consider several key features that can significantly impact efficiency and productivity. First, the machine's capacity, measured in tons, should align with the material thickness and type you frequently work with. A shear press with adjustable capacity can provide flexibility, allowing for a broader range of applications.

Additionally, the speed of the machine plays a vital role; faster operation can lead to increased output, making it essential to find a balance between speed and precision.

Another critical feature to consider is the type of control system. Modern shear press machines often come equipped with advanced CNC (Computer Numerical Control) systems that enhance precision and repeatability. These systems allow for programming of complex cuts and significantly reduce the potential for human error.

Furthermore, it's important to examine the overall build quality and durability of the machine. Choosing a robust design can lead to lower maintenance costs and longer lifespans, ultimately providing better value over time. Prioritizing these features will help ensure you select a shear press machine that meets your production demands efficiently.

Top 5 Brands of Shear Press Machines for Manufacturing Excellence

When it comes to maximizing manufacturing efficiency, investing in high-quality shear press machines is crucial. Among the myriad of options available, a few brands stand out for their exceptional performance and reliability.

One of the leading names in this industry is AMADA. Known for their innovative technology and robust design, AMADA shear presses are engineered to ensure precision and speed, making them a favorite for metalworking professionals.

Another renowned brand is TRUMPF, which combines advanced software solutions with their machines, allowing for seamless integration into existing manufacturing processes. Their shear press machines are celebrated for their energy efficiency and low maintenance requirements.

Similarly, JIER, a prominent player in the market, offers machines that emphasize durability and user-friendliness, catering to both small and large-scale manufacturing needs.

These top brands not only enhance production capabilities but also contribute to manufacturing excellence with their cutting-edge shear press technology.

How to Maintain Your Shear Press Machine for Long-lasting Performance

Maintaining your shear press machine is crucial for ensuring its longevity and optimal performance in the manufacturing sector. According to a report by the American National Standards Institute (ANSI), regular maintenance can extend the lifespan of industrial machines by as much as 30%, reducing downtime and increasing overall productivity. This is particularly important for shear press machines, which require precise alignment and functionality to deliver consistent results in cutting and forming operations.

To maintain your shear press machine effectively, it is essential to adhere to a rigorous maintenance schedule that includes regular inspections, lubrication, and calibration checks. Data from the International Journal of Machine Tools and Manufacture highlights that machines that undergo routine maintenance have a 50% lower rate of unexpected failures compared to those that do not. Additionally, operators should be trained to identify early signs of wear and tear, ensuring that any issues are addressed before they lead to critical breakdowns. By investing time and resources in maintaining shear press machines, manufacturers can achieve maximum efficiency and minimize costly repairs.

The Role of Shear Press Machines in Streamlining Production Processes

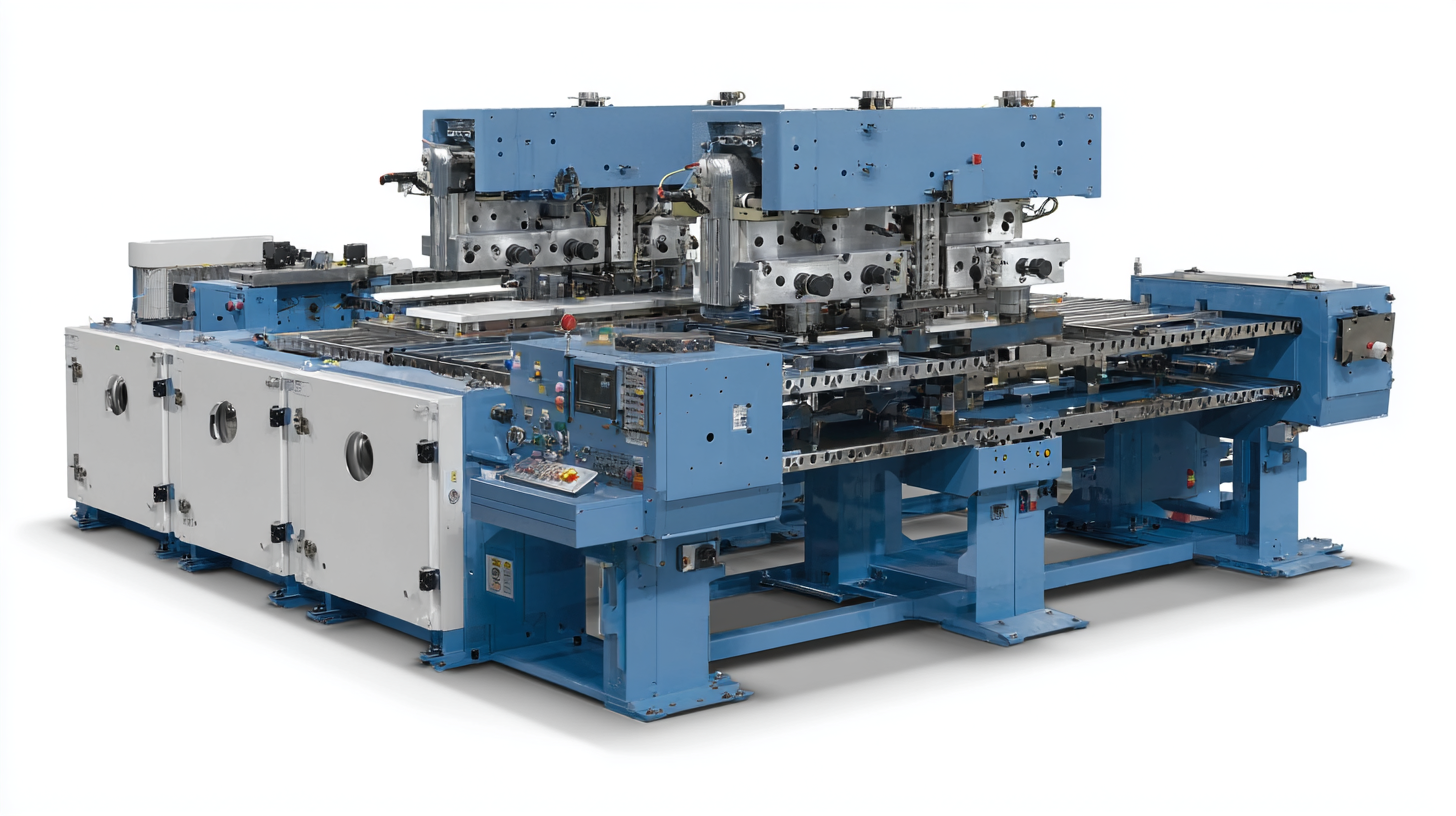

Shear press machines play a pivotal role in modern manufacturing, acting as essential tools that streamline production processes. By utilizing significant force to cut or shape materials, these machines enhance efficiency and accuracy in industries ranging from automotive to aerospace. Their ability to deliver high precision while reducing material waste makes them indispensable for companies aiming to optimize their manufacturing workflows.

When selecting a shear press machine, consider the material type and thickness you'll be working with. This ensures you choose a machine capable of handling the specific demands of your production line. Additionally, regular maintenance is crucial. Keeping the equipment in top condition not only prolongs its lifespan but also ensures consistent performance, which is vital for maintaining production speed and quality.

For manufacturers looking to maximize their operational efficiency, investing in automation technology can also be beneficial. Automated shear press machines can significantly speed up the cutting process while minimizing human error. Incorporating such innovations will help streamline your production processes further and enhance overall productivity.

Comparative Analysis: Hydraulic vs. Mechanical Shear Press Machines

When it comes to shear press machines, a critical decision manufacturers face is choosing between hydraulic and mechanical options. Hydraulic shear press machines utilize fluid power to deliver force, which offers several advantages. They provide smoother operation, better load distribution, and more precision in handling varying materials. This versatility is particularly beneficial for complex cutting tasks, allowing for intricate shapes and designs without compromising the quality of the finish. Additionally, hydraulic machines can easily adjust the pressure, accommodating materials of different thicknesses and hardness.

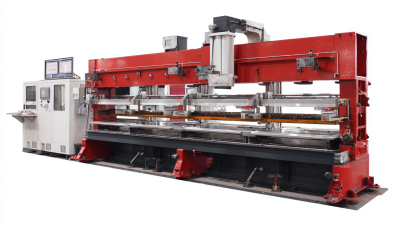

On the other hand, mechanical shear press machines are known for their speed and efficiency. These machines use a direct mechanical mechanism to produce rapid movements, making them more suitable for high-speed production environments. With fewer operational components, mechanical shear presses tend to require less maintenance and provide a more cost-effective solution for straightforward cutting tasks. While they may not offer the same level of adaptability as hydraulic machines, their simplicity often translates into greater reliability in high-volume production scenarios. Ultimately, the choice between hydraulic and mechanical shear press machines will depend on the specific requirements of the manufacturing process, such as the complexity of the cuts, production speed, and operational budget.

Efficiency Comparison of Hydraulic vs. Mechanical Shear Press Machines

Related Posts

-

Unwavering Quality from Trusted Chinese Manufacturers Best Shear Press Solutions

-

Ultimate Shear Press Guide: Mastering Efficiency and Precision in Your Production Line

-

Unleashing Excellence in Metalworking with Chinas Premier Hydraulic Brake Press Solutions

-

Discover the Advantages of Choosing the Best Press Brake for Your Manufacturing Needs

-

Unlocking Global Trade with Best Hydraulic Metal Shear Machine Import and Export Certification Guide

-

Discover the Trustworthy Quality of China's Best CNC Press Brakes for Global Manufacturing Needs