Unlocking Precision: The Best Press Brake Machines from China’s Premier Manufacturing Factory

As industries continue to evolve with the increasing demand for precision and efficiency in metal fabrication, the press brake machine has emerged as a critical component in manufacturing processes worldwide. According to a recent market report by Research and Markets, the global press brake machine market is projected to grow at a CAGR of 4.2%, reaching USD 3.5 billion by 2026. This growth underscores not only the importance of advancements in technology but also the competitive edge provided by manufacturers, particularly from China. China's premier manufacturing factories have become synonymous with high-quality press brake machines, offering innovative features and superior performance tailored to meet diverse industrial needs. In this blog, we will explore the best press brake machines sourced from China's leading factories, showcasing their top-tier capabilities and the beneficial impact they can have on production efficiency.

Key Features to Evaluate When Selecting a Press Brake Machine

When selecting a press brake machine, several key features should be evaluated to ensure optimal performance and longevity. First, precision is critical; the machine must deliver accurate bends to meet demanding specifications. Features such as advanced control systems, including CNC technology, can significantly improve precision in operations. Additionally, pay attention to the machine’s capacities—different models offer varying tonnage and working length, which will impact the types of materials and thicknesses that can be processed.

Another essential aspect is the machine's versatility. A good press brake should support multiple tooling options and configurations to accommodate a wide range of bending applications. Look for machines that offer easy tool changes and adaptability to different projects. Durability and build quality are also vital, as investing in a well-constructed machine will reduce maintenance costs and downtime in the long run. By considering these key features, manufacturers can ensure they select the best press brake machine to enhance their operational efficiency and productivity.

Unlocking Precision: Performance Comparison of Press Brake Machines

Top Chinese Manufacturing Factories for High-Quality Press Brakes

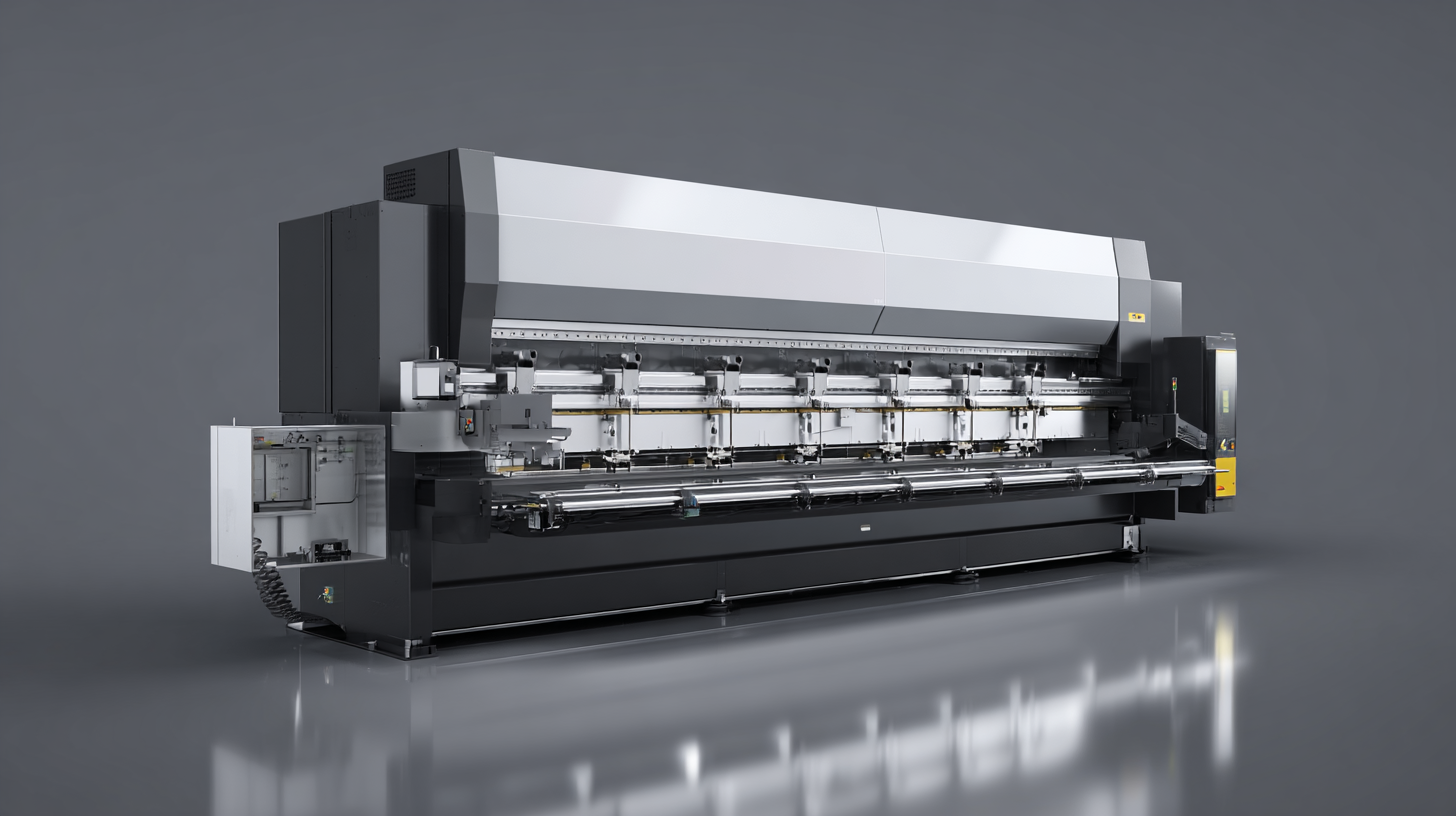

When it comes to precision engineering, selecting a high-quality press brake machine is crucial for manufacturers who seek to enhance their metal forming processes. China has emerged as a powerhouse in the manufacturing of such machinery, with several premier factories leading the way in innovation and quality. These factories utilize cutting-edge technology and adhere to international standards to produce press brakes that meet the diverse needs of their customers. For companies looking for reliability and durability, the top Chinese manufacturing factories offer a wide range of options that combine advanced features with cost-effectiveness.

The commitment of these leading factories to research and development ensures that their press brake machines are equipped with the latest advancements in hydraulics, control systems, and materials. Additionally, many of these manufacturers provide customizable solutions, allowing clients to specify unique features tailored to their production requirements. By leveraging local expertise and global insights, these factories not only enhance operational efficiency but also contribute to the rising standards of quality in the metalworking industry. For companies seeking a competitive edge, investing in press brakes from China's top manufacturers can unlock new levels of precision and productivity.

Comparative Analysis of Press Brake Technologies: Benefits & Limitations

The evolution of press brake technology has ushered in significant advancements in the manufacturing sector, particularly in China. According to a recent report by the International Press Brake Association (IPBA), the demand for precision metal forming machinery has surged by 20% in the last five years, driven largely by industries such as automotive and aerospace.

The modern press brakes, equipped with CNC technology, offer enhanced accuracy increases that can reach up to 0.01mm, minimizing material waste and improving overall production efficiency. Companies leveraging these machines can expect to see reductions in lead times by approximately 30%.

The modern press brakes, equipped with CNC technology, offer enhanced accuracy increases that can reach up to 0.01mm, minimizing material waste and improving overall production efficiency. Companies leveraging these machines can expect to see reductions in lead times by approximately 30%.

However, embracing this technology comes with its own set of limitations. While CNC press brakes provide unparalleled precision, they are significantly more expensive than their mechanical counterparts, with initial investment costs that can exceed $100,000. Additionally, complex programming requirements necessitate skilled labor, which can be a bottleneck for some manufacturers.

Reports indicate that skilled workforce shortages in the metal fabrication industry could impact productivity, with more than 40% of companies citing challenges in sourcing skilled operators. Understanding these benefits and limitations is crucial for manufacturers to make informed decisions in their production processes as they seek to enhance their capabilities.

Essential Maintenance Tips for Longevity of Press Brake Machines

Proper maintenance is crucial for ensuring the longevity and optimal performance of press brake machines. Just like summer maintenance for fire trucks or tractors, these machines require attention to detail to operate efficiently over time. Regular checks on essential components such as hydraulic systems, electrical connections, and mechanical parts can prevent costly breakdowns and extend the life of the equipment.

One key aspect of maintenance is the lubrication of moving parts. Keeping all joints and pivots well-greased will reduce friction and wear, enabling smoother operation. Additionally, checking and replacing filters and hydraulic oil at recommended intervals is vital to maintain system efficiency. Ignoring these simple steps can lead to major issues down the road, impacting productivity and increasing repair costs. By implementing these maintenance tips, operators can unlock the full potential of their press brake machines and ensure they serve their intended purpose for many years to come.

Cost Considerations: Budgeting for Your Press Brake Investment

When investing in press brake machines, it's crucial to consider your budget carefully. The initial purchase price is only one aspect of the total cost of ownership, which includes installation, maintenance, and operational costs. Recent industry reports indicate that the average price range for a reliable press brake machine from premier Chinese manufacturers can vary significantly, with basic models starting around $10,000 and advanced systems reaching upwards of $100,000. Additionally, efficiency improvements from modern machines can lead to a decrease in operational costs, potentially offsetting higher upfront expenses.

Here are some tips to keep in mind when budgeting for your press brake investment:

1. **Assess Your Needs:** Before purchasing, evaluate your production requirements. This includes material types, thickness, and volume of production. This assessment helps in selecting the right machine, which can save costs in the long run.

2. **Consider Total Cost of Ownership:** Beyond the purchase price, think about energy consumption, maintenance schedules, and potential downtime. Machines with better energy efficiency can lead to significant savings on utility bills while advanced robotics features can enhance productivity.

3. **Explore Financing Options:** Many manufacturers and suppliers offer financing solutions. Investigating leasing or installment payment plans can help in managing cash flow while acquiring high-quality press brake machines necessary for your operations.

Investing wisely in press brake technology will not only bolster production quality but also ensure long-term financial sustainability in an evolving market.