Best Industrial Press Options for Your Manufacturing Needs?

In the ever-evolving world of manufacturing, the choice of an industrial press can make or break production efficiency. Experts like John Smith, a renowned industry consultant, emphasize the importance of selecting the right equipment. He once said, "The wrong industrial press can lead to costly delays and inefficient processes."

Choosing an industrial press involves understanding specific production needs. Factors like capacity, precision, and speed play crucial roles. Many manufacturers overlook these details, leading to suboptimal performance. This oversight can hinder the entire production line.

Moreover, the variety of options available may overwhelm decision-makers. Balancing cost and quality is essential. A cheaper press might seem appealing but could result in frequent malfunctions. Reflecting on past experiences highlights the significance of this choice. Investing time in researching the best press can yield significant long-term benefits.

Overview of Industrial Press Types and Their Applications

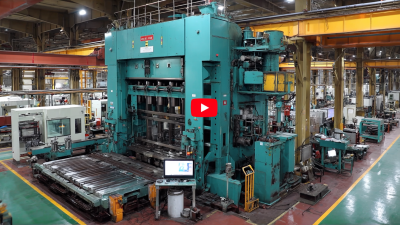

Industrial presses are vital for various manufacturing processes. These machines come in different types and serve multiple applications. Understanding the right press for your needs can significantly enhance productivity.

Hydraulic presses are known for their versatility. They can handle heavy-duty tasks with ease. According to a recent industry report, the demand for hydraulic presses is expected to grow by 6% annually. They are commonly used in metal forming and plastic molding. Their ability to apply uniform pressure makes them ideal for intricate designs.

Mechanical presses, on the other hand, are faster and suitable for mass production. They can achieve high stroke rates and are perfect for stamping and shearing operations. However, they may lack the flexibility of hydraulic presses. Always assess your production volume before choosing a type.

Tips: When evaluating presses, consider the maintenance costs. Budget for both operational and unforeseen expenses. Also, training staff on new equipment is crucial for safety and efficiency. Remember, investing time in proper training can prevent costly mistakes.

Best Industrial Press Options for Your Manufacturing Needs

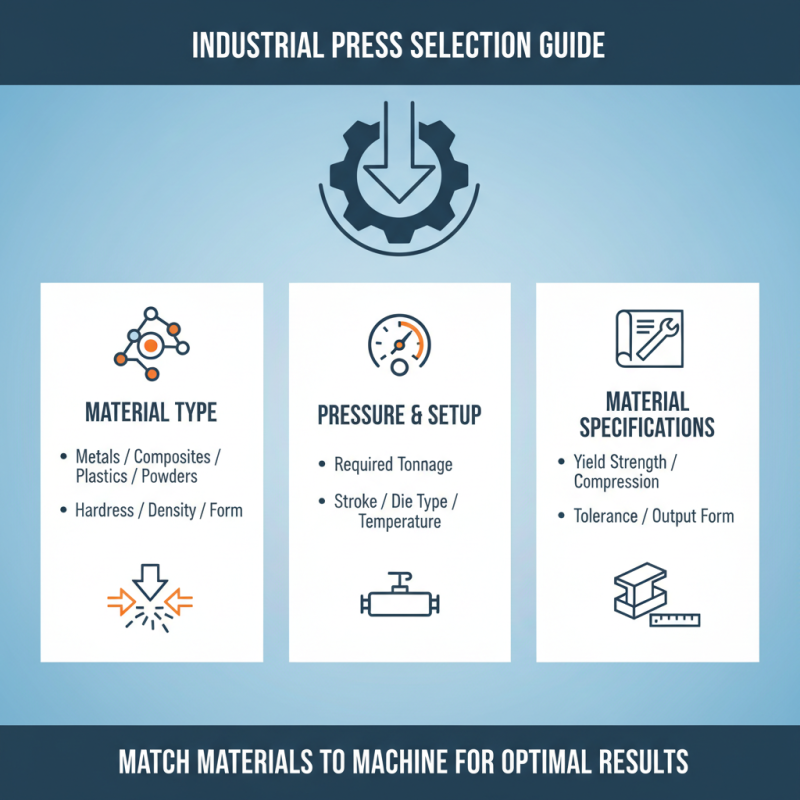

Key Factors to Consider When Selecting an Industrial Press

When selecting an industrial press, several key factors come into play. The type of materials you’ll be pressing is crucial. Different materials require different pressures and setups. Consider the specifications of your materials. This knowledge guides you toward the right machine. A mismatch can lead to subpar results or even equipment failure.

The press's capacity is another essential element. This refers to the maximum size of the material it can handle. If the capacity is too small, it can limit production. You might find yourself needing additional machinery down the road. Economic implications of this can be significant. Analyze your current production needs alongside potential future demands. It's a delicate balance to strike.

Moreover, think about operational safety. Industrial presses can be dangerous without proper safeguards. Look for features that enhance safety, like automatic shut-off systems. These are not just nice-to-haves; they are critical. Training staff on proper handling is also necessary. Neglecting safety measures can lead to serious consequences, not only legally but also morally. Each of these factors demands thoughtful consideration to ensure you make a responsible choice.

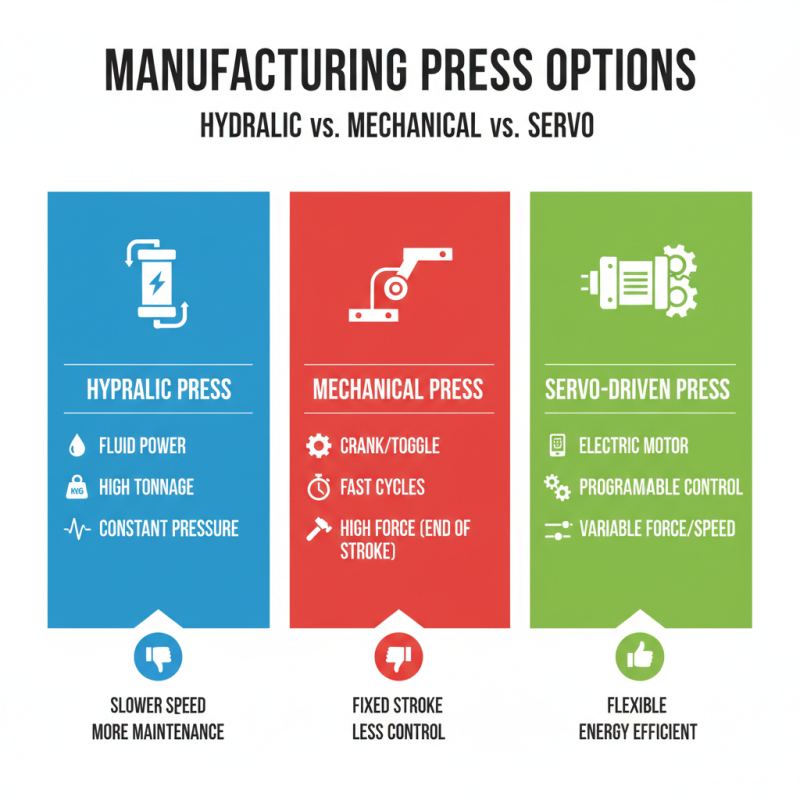

Comparison of Hydraulic, Mechanical, and Servo-Driven Press Options

When considering press options for manufacturing, it's essential to understand the differences between hydraulic, mechanical, and servo-driven presses. Hydraulic presses utilize fluid power to generate force. This option excels in tasks requiring high tonnage. They can produce constant pressure throughout the stroke. However, these presses may lack speed for rapid operations. The maintenance of hydraulic systems can also be more demanding.

On the other hand, mechanical presses rely on a flywheel mechanism. They are favored for their speed and efficiency in high-volume production. These presses can achieve higher production rates. Yet, they may suffer from variation in force throughout the stroke. This inconsistency can lead to flaws in precision tasks. Workers must be vigilant about these variations during operation.

Servo-driven presses are a modern alternative, providing flexibility and control. They combine speed and efficiency with adaptability to various tasks. This option allows for programming of different stroke profiles. However, initial costs may deter some manufacturers. It's crucial to weigh these factors carefully based on specific production needs. Each press type presents its own strengths and weaknesses. Understanding these can lead to better manufacturing outcomes.

Maintenance and Safety Practices for Industrial Press Equipment

Industrial presses play a crucial role in manufacturing. However, improper maintenance can lead to accidents and inefficiency. A study by the National Institute for Occupational Safety and Health (NIOSH) indicates that inadequate maintenance contributes to 29% of industrial accidents. Regular checks on equipment can help reduce these risks.

Safety practices are vital in operating industrial presses. Ensure all operators are trained in proper safety protocols. Implementing checklists for daily inspections is essential. These checklists can help catch potential issues early. Moreover, the American Society of Safety Professionals (ASSP) recommends conducting routine safety drills. This keeps workers aware and prepared for possible accidents.

Visual cues can also enhance safety practices. Clearly mark danger zones around press machines. Use bright colors and signs to alert workers. Regularly review these safety measures, as work environments change. Over time, even small neglects can lead to significant safety concerns. Maintenance isn't just about machinery; it's about ensuring a safe workplace for everyone.

Best Industrial Press Options for Your Manufacturing Needs

| Press Type | Capacity (Tons) | Stroke Length (inches) | Speed (Strokes/min) | Power (HP) | Safety Features |

|---|---|---|---|---|---|

| Hydraulic Press | 100 | 10 | 15 | 10 | Emergency Stop, Safety Guards |

| Mechanical Press | 50 | 8 | 30 | 7.5 | Light Curtains, Two-Hand Control |

| Pneumatic Press | 20 | 6 | 60 | 5 | Pressure Sensors, Automatic Shutoff |

| Servo Press | 75 | 12 | 25 | 15 | Force Control, Safety Shields |

Innovative Technologies Shaping the Future of Industrial Presses

The landscape of industrial presses is rapidly evolving. Innovative technologies are driving efficiencies and redefining manufacturing processes. Automation plays a critical role here. It reduces manual labor while increasing precision. Smart sensors and data analytics allow real-time monitoring, enhancing decision-making and improving output quality.

Additive manufacturing is another game-changer. It enables the creation of complex components that traditional methods struggle with. However, not all industrial presses are adapting. Some may resist these changes, fearing disruption. They must reflect on their stance. Embracing new technologies can lead to long-term benefits.

Moreover, sustainability is becoming paramount. Using energy-efficient presses can lower operational costs. Yet, some facilities still rely on outdated equipment. This creates an opportunity gap in competitive markets. Companies need to evaluate their current strategies. Staying relevant means recognizing the need for transformation.

Related Posts

-

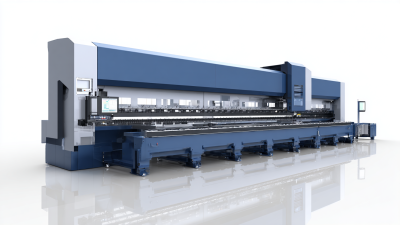

Maximize Your Metalworking Efficiency with the Latest Press Brake Innovations

-

2025 Top Hydraulic Press Brake Buying Guide for Efficient Metalwork

-

Comprehensive Manual Press Machine Guide: Everything You Need to Know for Optimal Use

-

Global Reach with China's Top Hydraulic Metal Shear Machines: Precision Engineering Redefined

-

Unmatched Quality in China Delivering the Best Press Machine for Global Buyers

-

Meeting Industry Production Standards with the Best Hydraulic Press Brake Machine for Optimal Efficiency