Understanding the Benefits of the Best Industrial Press Machine in Manufacturing

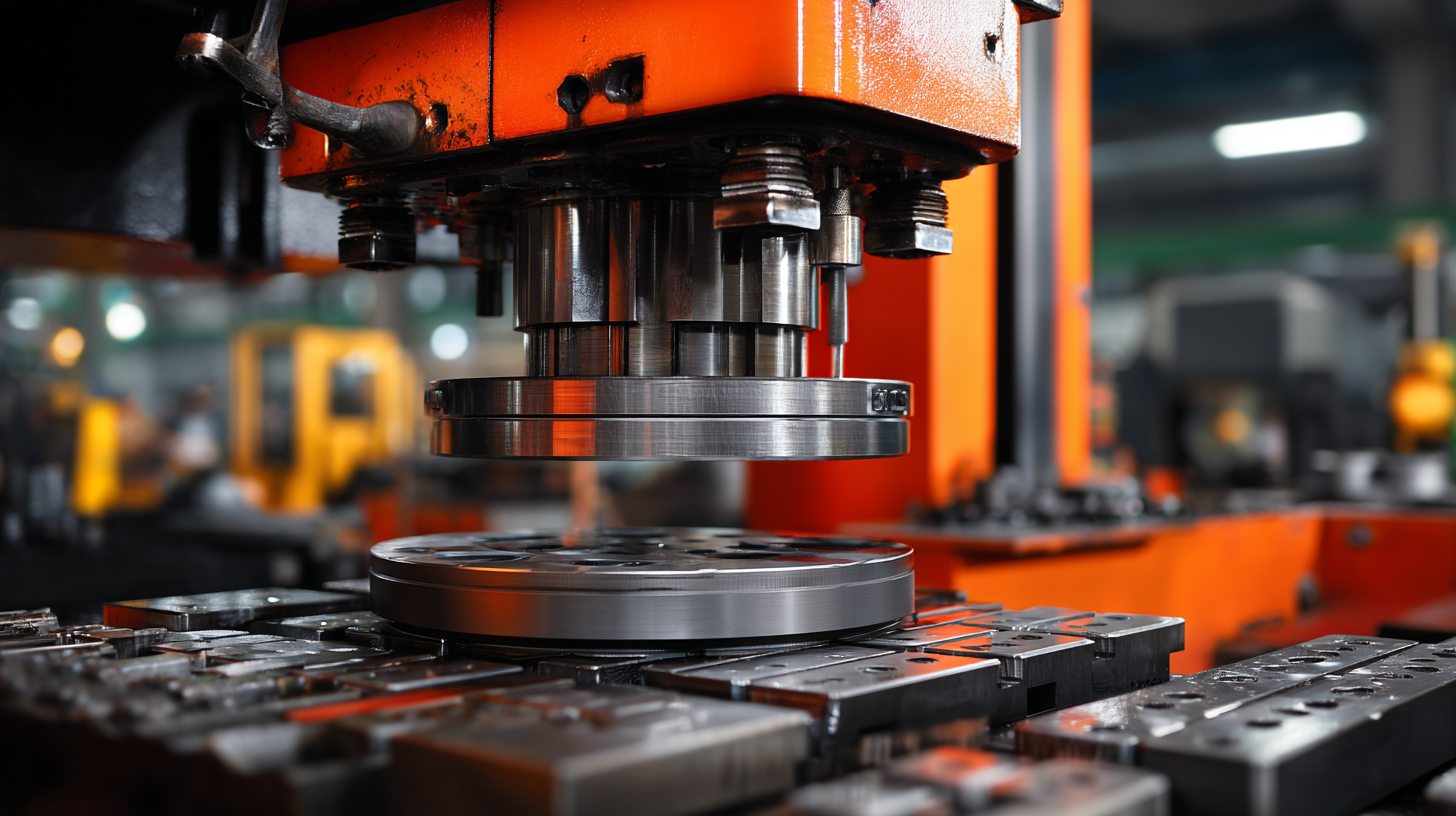

In today's competitive manufacturing landscape, understanding the capabilities and advantages of the best industrial press machine is crucial for optimizing production processes and enhancing product quality. According to a report by Grand View Research, the global industrial press market is expected to reach USD 26.23 billion by 2025, driven by increasing demand for high-efficiency machinery in various sectors. These machines play a vital role in stamping, molding, and forming materials, making them indispensable in industries such as automotive, aerospace, and electronics. A well-chosen industrial press machine not only improves operational efficiency but also contributes to cost reduction and waste minimization. As manufacturers seek to adopt cutting-edge technology to stay ahead in their fields, it becomes imperative to assess the benefits of different types of industrial press machines to meet specific production needs and sustainability goals.

Benefits of Industrial Press Machines in Streamlining Production Processes

Industrial press machines play a vital role in modern manufacturing, serving as the backbone of many production processes. One of the primary benefits of these machines is their ability to streamline operations, significantly reducing the time and effort required to produce high-quality components. By automating tasks like stamping, punching, and forming, industrial press machines eliminate manual intervention, which not only accelerates production but also minimizes human error. This efficiency is especially crucial in industries where precision and consistency are paramount.

Additionally, industrial press machines contribute to cost savings by optimizing material usage and reducing waste. With advanced features like programmable settings and precise controls, manufacturers can achieve intricate designs and shapes, ensuring that every piece of material is utilized effectively. This not only lowers raw material costs but also enhances overall output quality. As businesses strive to remain competitive, investing in the best industrial press machines becomes essential for improving productivity and maintaining high standards in manufacturing processes.

Exploring Different Types of Industrial Press Machines and Their Applications

Industrial press machines are vital components in modern manufacturing, offering a range of applications across various industries. One common type is the hydraulic press, which utilizes hydraulic force to shape or mold materials. Its ability to generate immense pressure makes it ideal for forging, molding plastics, and compressing metal components. In industries like automotive and aerospace, hydraulic presses are indispensable for ensuring precision and strength in the final products.

Industrial press machines are vital components in modern manufacturing, offering a range of applications across various industries. One common type is the hydraulic press, which utilizes hydraulic force to shape or mold materials. Its ability to generate immense pressure makes it ideal for forging, molding plastics, and compressing metal components. In industries like automotive and aerospace, hydraulic presses are indispensable for ensuring precision and strength in the final products.

Another popular category is the mechanical press, which operates using a flywheel mechanism to deliver consistent pressure. Mechanical presses are commonly used for stamping, blanking, and forming sheet metal. Their high speed and efficiency make them suitable for high-volume production runs, where accuracy and repeatability are crucial. Additionally, there are servo presses, which combine the benefits of mechanical and hydraulic presses, offering flexibility in speed and force control, making them suitable for complex applications in the electronics and appliance sectors. Each type of industrial press machine plays a crucial role in enhancing productivity, quality, and innovation in manufacturing processes.

Key Features to Consider When Choosing an Industrial Press Machine

When choosing an industrial press machine, several key features should be meticulously evaluated to maximize efficiency and productivity in manufacturing processes. First and foremost, consider the machine's tonnage capability. This determines the amount of force the press can apply, making it crucial for processing different materials. For instance, a higher tonnage is required for harder materials, while lower tonnage suffices for softer ones. Additionally, assess the machine's stroke length and speed, as these factors can significantly affect the cycle time and overall throughput.

Another important aspect to consider is the construction quality and durability of the press machine. Machines built with high-quality materials tend to withstand the rigors of industrial use better, leading to lower maintenance costs and longer service life. Furthermore, operators should look for features such as advanced safety mechanisms, user-friendly control systems, and versatility in applications. These elements not only enhance the safety and operational efficiency of the press but also provide flexibility to adapt to various manufacturing needs, ensuring that businesses can stay competitive in a rapidly evolving market.

Comparative Analysis of Traditional vs. Modern Press Machines

The landscape of industrial press machines has undergone a significant transformation in recent years, with traditional machines now facing competition from advanced modern alternatives. Traditional press machines, often characterized by their mechanical operation and limited capabilities, have been a staple in manufacturing for decades. However, modern press machines leverage automation, precision engineering, and enhanced efficiency, offering substantial advantages. According to a report by MarketsandMarkets, the global industrial press market is expected to reach USD 20 billion by 2025, fueled by the growing demand for high-quality manufacturing processes.

When comparing these two types of machines, one must consider factors such as production speed, energy efficiency, and the flexibility of operation. Modern press machines frequently outperform traditional counterparts, reducing cycle times by up to 30% and significantly lowering energy consumption—saving companies an estimated 20% on operational costs, as noted by a study from the Association for Manufacturing Technology.

**Tip**: When evaluating press machines for your operations, assess the specific needs of your production line. Consider the long-term costs and benefits associated with upgrading to modern technology, including potential increases in output and savings in energy bills. Also, ensure that you factor in the training required for your workforce to adapt to new machinery. Embracing innovation can ultimately enhance the competitiveness of your manufacturing processes.

Understanding the Benefits of the Best Industrial Press Machine in Manufacturing - Comparative Analysis of Traditional vs. Modern Press Machines

| Feature | Traditional Press Machines | Modern Press Machines |

|---|---|---|

| Operation Mode | Manual or semi-automated | Fully automated with sensors |

| Production Speed | Slower due to manual intervention | Higher speed with less downtime |

| Energy Efficiency | Lower efficiency, higher energy costs | Higher efficiency with advanced technologies |

| Initial Investment | Lower initial costs | Higher initial costs but long-term savings |

| Maintenance | Regular maintenance, higher labor costs | Reduced maintenance due to advanced design |

| Versatility | Limited to specific tasks | Highly versatile, can adapt to various processes |

| Operator Skill Level | Requires skilled operators | Less skill required due to automation |

Cost-Effectiveness and Efficiency: The Bottom Line for Manufacturers

In the competitive landscape of manufacturing, the integration of advanced industrial press machines is crucial not only for enhancing operational efficiency but also for ensuring cost-effectiveness. According to a report by Mordor Intelligence, the industrial machinery market is projected to grow at a CAGR of over 5% from 2021 to 2026. This growth is largely attributed to the increasing demand for precision, reliability, and productivity, with manufacturers seeking solutions that optimize their processes while reducing operational costs.

Cost-effectiveness is primarily achieved through reduced material waste and minimization of downtime. A study by the National Institute of Standards and Technology (NIST) found that manufacturers leveraging advanced press technology can decrease production costs by up to 30%. Additionally, modern industrial press machines incorporate automation and smart technology, which not only streamline operations but also enhance output quality.

As a result, manufacturers who invest in the best industrial press machines are not just saving money; they are also positioning themselves to meet evolving industry standards and consumer expectations.