What is a Ball Screw and Where to Find It for Sale?

A ball screw is an essential component in various machinery. It converts rotational motion into linear motion with high efficiency. Many businesses rely on ball screws for precise movement in their applications.

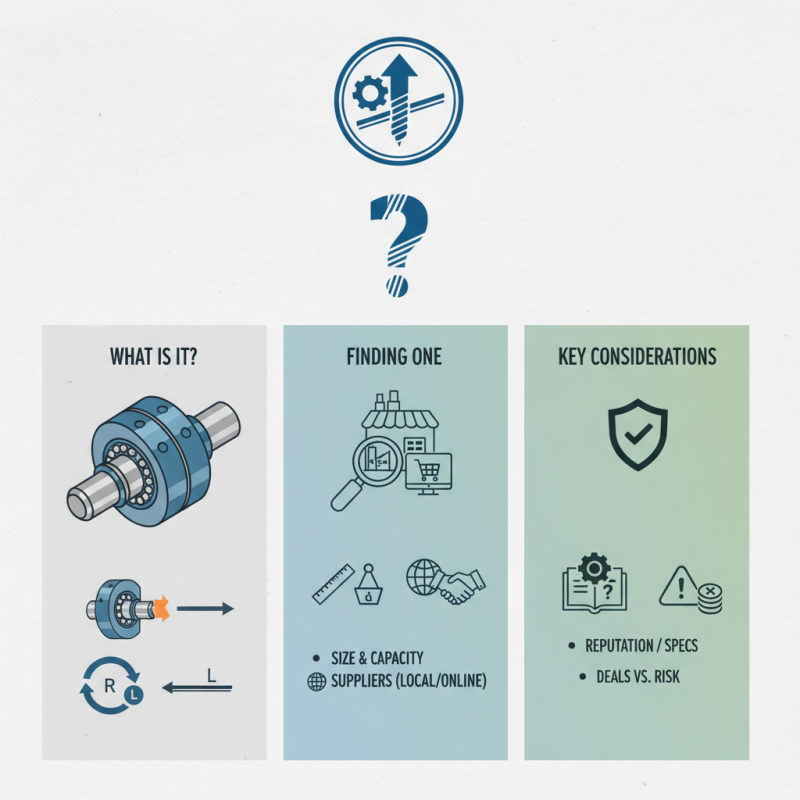

If you're exploring options, you might be looking for a ball screw for sale. The market offers a range of sizes and specifications. It can be overwhelming to choose the right one. Pay attention to details such as load capacity and dimensions.

Consider the suppliers available to you. Research both local and online sources. It's crucial to find a reputable dealer. Sometimes, you may find great deals, but there's a risk involved. Make sure to review product specifications thoroughly.

What is a Ball Screw and Its Basic Components?

A ball screw is a mechanical device that converts rotary motion into linear motion. This mechanism uses ball bearings that roll between screw threads. Its design allows for high efficiency and low friction. The primary components of a ball screw include the screw shaft, ball nut, and a series of precision balls. Each of these elements works together to ensure smooth movement.

The screw shaft is typically made from high-strength steel. This material offers durability and longevity. Meanwhile, the ball nut houses the balls and is responsible for translating the rotary movement of the screw into linear motion. It is often the most complex part, featuring precision threads designed for specific applications.

Understanding these components can help in selecting the right ball screw for various machinery. However, it’s essential to consider factors like load capacity and speed requirements. Not every ball screw fits every situation. One might underestimate the importance of precision. Choosing the wrong dimensions can lead to inefficiencies or even equipment failure. Always assess your specific needs before purchasing.

Understanding the Mechanism of Ball Screws: How They Work

Ball screws play a vital role in various mechanical systems. They convert rotary motion into linear motion. This mechanism is widely used in machines and CNC equipment. Understanding how they work can simplify many design processes. The ball screw has a threaded shaft and ball bearings. These bearings reduce friction and allow for smooth movement.

When the screw rotates, the balls travel along the screw's grooves. This design enables precise positioning. However, the efficiency can vary based on quality. Regular maintenance is essential. Without it, wear and tear can lead to failure. In addition, ensuring the alignment is crucial for optimal performance. A misaligned ball screw can cause binding or excessive wear.

Finding a ball screw for sale is straightforward. Many suppliers offer a range of sizes and specifications. It’s important to research before purchasing. Consider the application and specific requirements. Not every ball screw is suitable for every task. This selection process can be daunting. But taking the time to analyze will yield better results.

Applications of Ball Screws in Various Industries

Ball screws are essential components in many industries. They convert rotary motion into linear motion with high efficiency. This mechanism is widely used in applications such as CNC machinery, robotics, and aerospace equipment. Each application relies on the accuracy and smooth motion provided by ball screws.

In the automotive sector, ball screws help in precision steering systems. They enable quick and accurate adjustments, enhancing vehicle performance. In automation, they are crucial in robotic arms, allowing for precise movement and positioning. In the medical field, they power various devices that require high precision, improving patient outcomes.

**Tips:** Choosing the right ball screw involves considering load capacity and efficiency. Look for options that suit specific needs and applications. Regular maintenance is vital for their longevity and effectiveness.

In manufacturing, ball screws support conveyor systems. They ensure smooth transport of materials, increasing productivity. Yet, not all systems adapt easily; some may require modifications. Balancing the benefits of ball screws with system compatibility is essential.

What is a Ball Screw and Where to Find It for Sale? - Applications of Ball Screws in Various Industries

| Industry | Application | Ball Screw Size (mm) | Load Capacity (N) | Purchase Source |

|---|---|---|---|---|

| Manufacturing | CNC Machines | 16 | 3000 | Online Retailers |

| Aerospace | Landing Gear Actuation | 20 | 5000 | Specialty Suppliers |

| Automotive | Electric Vehicle Steering | 25 | 4000 | Industrial Distributors |

| Medical | Surgical Robots | 10 | 800 | Direct Manufacturers |

| Robotics | Automated Assembly Lines | 30 | 6000 | Engineering Firms |

Where to Buy Ball Screws: Top Retailers and Online Options

Ball screws are essential components in various machinery, providing precise linear motion. For those looking to purchase ball screws, several options are available. Online platforms, such as specialized machinery websites and marketplaces, are popular. These sites often offer a wide range of sizes and specifications. You can find ball screws tailored to your different applications.

Local suppliers also carry ball screws. Visiting a local distributor can provide immediate access to products. Many distributors have knowledgeable staff. They can help you choose the right ball screw for your needs. Retailers often provide custom solutions as well. It's an excellent option if you require specific dimensions or features.

Tip: Always check the technical specifications of the ball screw. Perform a compatibility check with your machinery. Ensuring accurate sizing can save time and resources.

While purchasing, consider reading customer reviews. They offer valuable insights into the product quality. Some buyers report discrepancies between expectations and actual performance. Being aware of potential issues helps refine your choices. Make informed decisions based on thorough research.

Factors to Consider When Purchasing a Ball Screw

When considering the purchase of a ball screw, several factors come into play. The lead screw's diameter and pitch are crucial. A larger diameter often means greater load capacity. However, this also leads to increased weight and space requirements. Choose the lead screw's pitch wisely to optimize speed and efficiency. A higher pitch allows for faster movement but may reduce precision.

Additionally, it's important to evaluate the material and surface treatment. Ball screws are typically made of steel or stainless steel. The right surface finish can enhance durability and reduce friction. As you shop, pay attention to the specifications. A mismatch might lead to operational issues later. Sometimes, the ideal choice may not be readily available.

Lastly, assess the supplier's reputation and support. Reliable suppliers often provide better warranties and customer service. It's essential to ask questions and clarify doubts. Don't rush into a decision; take time to reflect on your needs. A thoughtful choice can lead to better performance in the long run.